A Japanese startup claims to be developing a machine that can make its own materials.

The company is SUN METALON, launched only in 2021. Their vision is quite unique:

“SUN METALON aims to create a world where metal products can be produced from local ores anywhere in the world.”

This is a bold vision that is quite different from any other metal 3D printer manufacturer. Typically today’s high performance metal 3D printers require third parties to develop highly refined metal powders. Often the print quality is quite dependent on the quality of the input powder, so the notion of a machine making its own metal materials is certainly radical.

The mystery is how, exactly, they intend on doing this. It’s likely they’re thinking of a separate device that could accompany the 3D printer that would prepare the printable materials from raw ores. They also say:

“Nowadays, iron ore is melted in blast furnaces of large steel mills to produce iron.

Can you imagine a world in which it is possible to create the necessary metal parts using materials available on the spot?”

However, there are a number of clues in their less-than-detailed technology webpage that hint at how all this is to work.

The device will 3D print entire layers at once, similar as does MSLA, which should lead to far faster print speeds. SUN METALON said the print speed is “500 times faster than conventional 3D printing methods”.

They say the device will achieve prints at 10X less cost, which might have something to do with the material preparation. Typical metal powders are extraordinarily expensive, and they drive up the price of today’s metal prints.

SUN METALON said their “secure production platform” is scalable and is able to “integrate” into a manufacturing environment.

The machine specifications are brief and describe three machines:

| SUN METALON 1.0 | SUN METALON 2.0 | SUN METALON 3.0 | |

| Release | 2023 1H | 2024 2H | 2026 1H |

| Productivity | 20 parts / day | 50 parts / day | 250 parts / day |

| Part Density | 98% | 98% | 98+% |

| Print Size | 150*150*400mm | 500*500*500mm | 1000*1000*1000mm |

The first machine to emerge is notably smaller, likely in order to prove the concept and figure out many of the non-machine details of their business.

I’m very curious about how the machine works. In the sole concept image of the device they provide, there are some very intriguing clues.

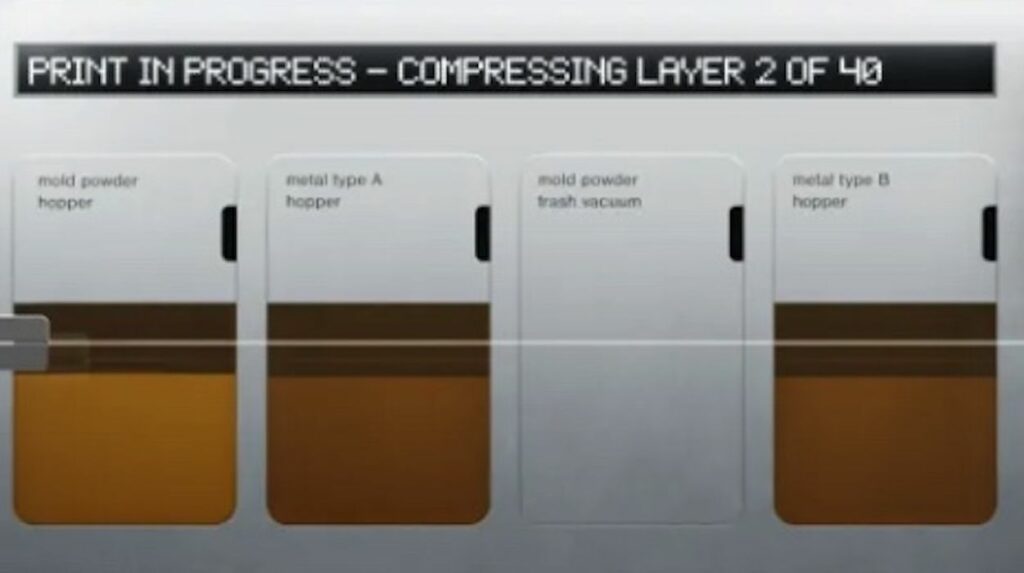

The machine’s display says “PRINT IN PROGRESS – COMPRESSING LAYER 2 OF 40”.

This tells us that the machine does print layer by layer, and that there is a “compression” sequence that is being done to each layer. I’ve seen a compression technique previously (most notably with Thermwood’s polymer process), but on metal it could be unique.

The component labels are also interesting:

- Mold powder hopper

- Metal type A hopper

- Mold powder trash vacuum

- Metal type B hopper

What does all this mean? Honestly, I have no idea. This is VERY different from the information you’d see on typical metal 3D printers. But let’s do some speculation.

There is clearly molding going on, which could be a way to speed up printing, as casting is far faster. What if the machine 3D printed molds, and then raw ore was somehow smelted down and poured into the mold? That would certainly be fast, once the metal was sufficiently heated. It may also require compression on layers to force out air pockets.

There’s also the two “types” of metal hoppers. Does this mean the device can handle two types of metals? Note that the labels don’t say “storage bin 1 and 2”, but instead refer to “types” of metals.

At the bottom of the machine, there appears to be two removable drawers with handles. Could these be removable build chambers? With the likely high heat involved in this process, the builds would almost certainly require considerable time to cool down. By making the chambers removable, the printer could proceed on subsequent prints while the first run cools down.

There are other elements to this image that are baffling. What is the yellow striped piece for? What is the curious red-white-black display at the top doing? Does that huge square element on the left slide along the front of the machine? What does it do?

I have no answers for these, but there is little doubt that SUN METALON’s machine is very different from typical metal 3D printers.

The company is well funded from a series of investors — who likely know a lot more about their process than is publicized.

We’ll have to wait until SUN METALON releases more information, which is likely to happen before the first machines is released next year.

Via SUN METALON (Hat tip to Benjamin)