Charles R. Goulding and Preeti Sulibhavi discuss how the construction industry is about to be disrupted.

John Fish, CEO of SUFFOLK (a Boston-based construction company), made his fortune in the US$2.1 trillion construction industry. Now, he is looking to disrupt the industry that helped him become a billionaire. How?

Through technology.

It is a well-known fact that innovation has lagged in the construction industry during the last half of this century. Some may even argue that productivity has gone down. But that is all changing with SUFFOLK’s investing arm, Suffolk Technologies.

Below is a table of 40 companies in Suffolk Technologies’ investment portfolio:

| Company | Industry Description |

| Agorus | Robotics and software management |

| Airworks | AI software for aerial remote sensing for basemaps |

| Augmenta | Construction platform that uses AI to be compliant |

| BRUNT | Work boots and apparel for construction industry |

| BuildClub | An app for building material suppliers to deliver |

| CalcTree | No-code web app that integrates tools for engineers and designers (A&E software) |

| Canvas | Construction robotics |

| Carbon Title | Platform to neutralize building carbon impact by tracking carbon credits and CO2 emissions |

| Constrafor | Cloud-based software for invoice tracking and admin tasks for construction industry |

| Diamond Age | Large-scale robotics and 3D printing/automation at industrial scale for home-building |

| Ediphi | Pre-construction platform bringing design teams and contractors together for cost estimates and take-offs |

| Emidat | AI for climate intelligence and construction insight for building material manufacturers |

| Equipment Share | Contractor equipment software |

| Exodigo | Subsurface mapping solutions using advanced sensors, 3D imaging and AI |

| Felux | SaaS platform for supply chain solutions (suppliers, buyers, tracking shipments, etc.) |

| Flexbase | Credit card provider for construction SMBs |

| Hammr | Time tracking, payroll, scheduling, benefits and compliance |

| Handle | Manage online payments, waiver exchange lien management |

| Higharc | Homebuilding platform for design, construction and sales |

| HqO | Workplace experience platform |

| Kaya | AI-powered data and intelligence platform providing coordination during construction projects |

| Kojo | Materials management platform |

| MeasurabI | ESG solutions for real estate for measuring, managing and reporting ESG data |

| Moxion | Mobile energy storage changing environmental energy solutions |

| nPlan | AI forecasts for project outcomes based on historical data |

| Nyfy.ai | Automates job sites using SMS, QR codes and digital passes for construction site compliance |

| OpenSpace | Reality capture software with industry analytics |

| Outbuild | Construction software for scheduling, lookaheads and weekly plans |

| Placemakr | Hospitality living platform for property managers and real estate investors |

| PLOT | Delivery calendar, logistics map and structured messenger |

| Procore | Construction management platform |

| Pulley | Permitting platform for local permitting |

| QFlow | Real-time materials and waste data tracking software |

| Rugged Robotics | Autonomous vehicles that mark A&E designs on unfinished floors |

| SewerAI | Automatic detection of field conditions through drones, jetter cameras, CCTV crawler and digital side scanners |

| Sitelink | AR-powered collaboration platform for construction teams (commercial), using AR, AI and computer vision |

| Soil Connect | Construction software for bulk material supply, demand and logistic coordination |

| Trunk Tools | Tools for mobile platforms for the field |

| TrustLayer | Automates verification of insurance, licenses and compliance documents |

| WINT | AI to identify sources of damage, leaks, waste and carbon emissions |

Diamond Age

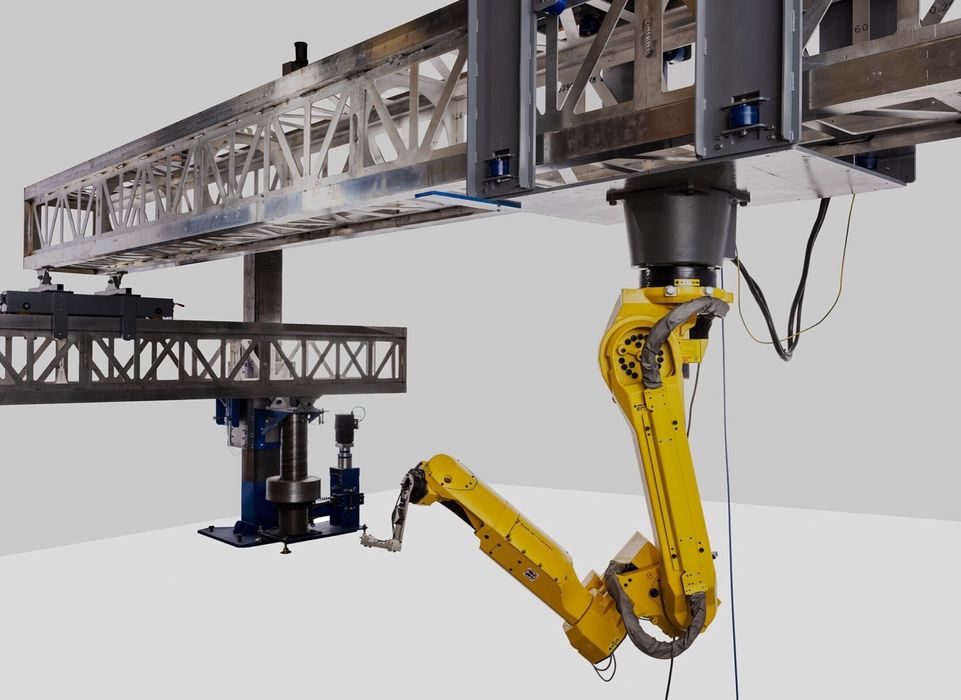

One company that stood out to us is Diamond Age. The company, based out of Phoenix, Arizona, is using 3D printing, automation and AI tools to transform home-building as we know it. In fact, Diamond Age plans on building climate-resilient houses that can withstand hurricanes and earthquakes.

Diamond Age, a leading full-stack robotics innovator dedicated to making homeownership more affordable through automation, has signed a Letter of Intent to work with Ukraine’s Ministry of Strategic Industries. The collaboration will harness Diamond Age’s cutting-edge automated concrete 3D printing technology to produce bunkers, supporting Ukraine’s ongoing war efforts.

The historic event was formalized in December of last year during a meeting at the Arizona State Capitol, attended by representatives from Ukraine, Diamond Age, and the Arizona Defense and Industry Coalition (AZDIC), alongside Arizona House Speaker, Ben Toma.

Widely recognized for its expertise in automated 3D printing processes in home construction, Diamond Age showcases its commitment to adapting this technology for broader societal benefits. CEO Jack Oslan expressed enthusiasm about the opportunity to rapidly assist Ukraine and envisioned the technology’s potential for rebuilding communities demolished by war.

“Today, Diamond Age takes a historic step, joining forces with Ukraine’s Ministry of Strategic Industries. Our cutting-edge 3D printing technology will create bunkers, not just for defense but as a symbol of hope and resilience. We’re not just innovating; we’re making a meaningful impact on lives,” said Oslan.

The Research & Development Tax Credit

The now permanent Research & Development Tax Credit (R&D) Tax Credit is available for companies developing new or improved products, processes and/ or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits

Conclusion

The success of Fish is impressive; his future ambitions are inspiring. To bring innovation to an industry that really needs it at this time, with few players in the market, is a risk, but if successful SUFFOLK and Fish will be pioneers in the construction industry with some help from 3D printing technology.