Charles R. Goulding and Preeti Sulibhavi discuss how 3D printing can be integrated into cost reduction strategies and increase revenue.

A lot of large companies are engaged in major cost reduction programs. This could make it more difficult to sell 3D printing technology to companies that are looking to cut costs, but it doesn’t necessarily have to.

The 3D printing industry must understand the markets and present 3D printed products as cost-reduction opportunities as opposed to simply additional expenses. Advancements in 3D printing technology have been significant in the past few years and corporate purchasing departments might not realize that the technology is more relevant to their operations than previously. They might miss this opportunity to use 3D printing to help automate and cut costs.

UPS

Now that the union and UPS have reached an agreement, labor costs will increase for UPS. UPS is looking to cut costs as a result of about US$200 million in lost sales. UPS has cut labor hours by about 10 percent and let go 2,500 management employees.

Unmanned Aerial Vehicles (AEVs) are a great way to still conduct business with fewer human employees. We have reported how UPS has been utilizing drones for some of its deliveries. In fact, Wingcopter, a German-based drone company, has designed a fleet of electric vertical takeoff and landing (eVTOL) drones for UPS.

The Federal Aviation Administration (FAA) has already given approval to UPS and Wingcopter, to begin construction of the fleet. The drones will be built by Flight Forward (UPS’ subsidiary company that focuses on drone-based deliveries).

Wingcopter has previously worked with Merck to create a system of inter-office drone delivery for the pharmaceutical giant. Wingcopter’s expertise in drone technology offers UPS incredible benefits, allowing them to deliver significantly more packages at higher speeds with fewer errors.

There are several drone parts that can be 3D printed, either for replacement or for repair. Whether is the motor, transmitter, or the CubePilot carrier board, 3D printers can create high-quality parts at low-cost and in less time than conventional manufacturing methods.

Rolls Royce

Rolls-Royce, the aircraft engine-maker, will slash up to 2,500 jobs in 2023, worldwide.

In fact, Rolls-Royce demonstrated a strong recovery in profit as the new CEO, Tufan Erginbilgic, put into place a turnaround plan that involved better pricing for maintain engines that power aircraft like the Airbus A350 and Boeing 787. Erginbilgic indicated that the five-fold increase in cash flow was a result of “greater productivity, efficiency, and improved commercial outcomes.”

As of the writing of this article, Rolls-Royce announced that it is targeting a fourfold increase in profits in the next four years. There will also be an additional 500 million euros in cuts planned over the same period.

With a strong MRO business environment, Rolls-Royce should be able to capture some nice income streams if it sets up the market systems to do so. 3D printing can be a part of this as the company is no stranger to such equipment.

Rolls-Royce has added to their jet engine portfolio by introducing UltraFan, which is 25% more fuel-efficient than first generation Trent engines, and can help create sustainable air travel. UltraFan’s intermediate compressor case (ICC) was manufactured in part by metal 3D printing techniques.

Stellantis

Now that Stellantis has reached an agreement with their labor union, ending a lengthy labor dispute, the company is faced with increased labor costs. Purchasing equipment at this time might not seem ideal, but this is exactly the right time to invest in automation and 3D printing.

Stellantis’ 3D printing lab, the Mopar 3D Lab, is one example of a burgeoning trend in the automotive industry. Automakers are embracing the 3D printing industry and empowering customers to personalize their vehicles. By providing a platform for owners to 3D print their own accessories, Stellantis is including those who wish to personalize their trucks. But there are more useful applications for 3D printing in the automotive industry.

Auto assembly plants have been using robots for small production items like spot welding and painting, but there are other applications for robots and automation throughout the production process as well.

Loading and unloading parts from equipment to other pieces of equipment is another example of a job that robots are capable of on the plant floor. Transferring parts, especially if they are heavy and unsafe for human handling, between points of production is another optimal use of robots and automation in the automotive industry.

Ford

The new labor deal reached by Ford and its workers’ union is expected to cost the company US$8.8 billion over the length of the four-year contract. As Ford pursues an expensive transition to electric vehicle (EV) production, the price-tag on the labor agreement is leading Ford to cut costs elsewhere. Ford is investing in automation as the cost of producing each vehicle will be US$900 more with this new contract in place.

While Ford has a daunting challenge ahead it is thinking strategically by looking for innovative solutions as opposed to just simply slashing costs based on its financials alone. Ford has increasingly been utilizing 3D printing technologies in recent years. Now, the 3D printing industry can play a part in Ford’s cost reduction strategy over the next few years by utilizing the technology for customized accessories and even replacement parts for some of its models.

Alstom

Alstom has announced 1,500 job cuts to its workforce. Most known for manufacturing France’s high-speed TGV trains, Alstom has reported that it is looking to shed about 1 billion euros in assets to improve cashflow, which is required to maintain its investment-grade credit rating.

This is an opportunity to integrate more robot automation on their production floors as well.

It would be an opportune time to purchase more innovative and efficient machinery and equipment (that could reduce other costs such as labor expense) at a time when older assets are being purged. No stranger to 3D printing, Alston has utilized 3D printing technology for its Italian AGV ETR575 high-speed, electric passenger train. To replace 200 parts for the train, Alstom decided to change its construction method, as their usual process was becoming too expensive to produce replacement parts. So, in 2022, Alstom turned to 3D printing technology.

Nokia

The electronics giant, Nokia, will be laying off 14,000 employees to address market concerns. The Finnish telecom giant, a major provider of 5G equipment, employs 86,000 people. Nokia can look for ways to supplement its labor force with more automation and 3D printing. There are many electronic applications of 3D printing as we have covered on Fabbaloo before in terms of the electronic products, such as semiconductors and circuit boards.

Jabil

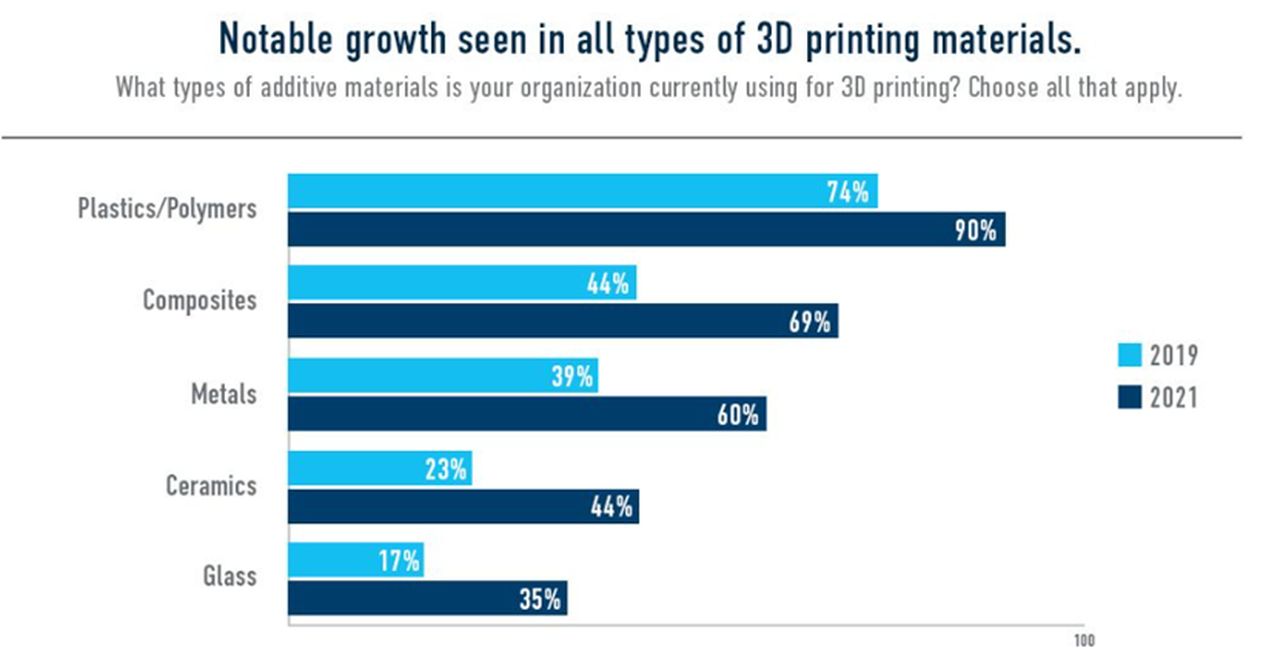

Jabil has indicated that it will embark on significant headcount reductions and restructuring that will cost the company approximately US$200 million to implement. In its Fremont, CA plant alone it has decided to cut 140 workers. Jabil is looking for ways to continue operations with lower costs. A global leader in “print” manufacturing, Jabil takes complex designs through manufacturing and validation by using 3D printing technology. Jabil has a comprehensive understanding of 3D printing’s value potential. The results of a Jabil survey on the issue are illustrated above. A little over 80% of respondents expect their 3D printing use for production parts to at least double within the next five years.

Jabil has world-class knowledge of 3D printing and expertise in applications for electronics manufacturing. We believe that Jabil can greatly benefit from the ongoing development of embedded electronics components as those being created by Nano Dimension.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Companies engaged in cost-cutting measures need to be strategic and reduce costs where appropriate while simultaneously investing for the future. The 3D printing industry needs to adapt to this environment and change sales strategies to emphasize how 3D printing can better reduce costs and increase revenue.