Sometimes technology is going just too far.

At a recent trade event I happened to cruise through the Stratasys booth, where the company exhibited their numerous 3D print technologies. One of them is their full color PolyJet process.

PolyJet has evolved quite a way since it was first introduced by Objet many years ago. Then it was a one-color process, but over time Stratasys has gradually added more print heads that allow more colors. Today it’s possible to 3D print with the full CYMK gamut, along with transparent, white and more.

With this capability it’s possible to 3D print objects with literally photorealistic quality.

Don’t believe me? Look up at that image. Of the banana.

It’s not a banana.

It’s a full color 3D print. And get this, if you squeeze it, it is squishy, just like a real banana. Check this out:

Near the banana, someone had left a piece of pizza.

Except it wasn’t pizza. It was yet another extraordinarily realistic full color 3D print.

There seems to be only two ways of detecting these prints are not “real”. One is by looking extremely closely at them. Consider this zoomed in view of the pizza surface:

Here you can begin to see some slight artifacts that give away that it’s really a 3D print.

The second method of uncovering a not-real pizza is to pick it up. It turns out that the PolyJet material used by Stratasys is somewhat heavier than natural materials found in pizzas or bananas. The pizza slice is quite heavy, and you’d immediately notice something is off.

Yes, you can, with some effort, determine that these items are in fact 3D prints and not the genuine article. But that’s saying something important: you have to WORK to figure this out.

Gone are the days when that object was “obviously” a 3D print, even with the shortest glance.

Stratasys’ full color power has never been better, but what can you do with it?

While you can 3D print common items like pizza and bananas, the real items are actually far less expensive than producing these full color 3D prints. A banana is less than a dollar to buy, while the print of it was likely hundreds of dollars.

This is the issue with full color 3D printing: what can you really use it for?

So far, Stratasys seems to have identified three areas of use.

One is for full color prototyping. There are some consumer products that depend utterly on their color and texture, and these can easily be swapped in and printed to produce replicas for evaluation. This capability would best be used in fashion industries, like footwear, where it is difficult to make a series of slightly different physical prototypes in traditional processes, or phone cases.

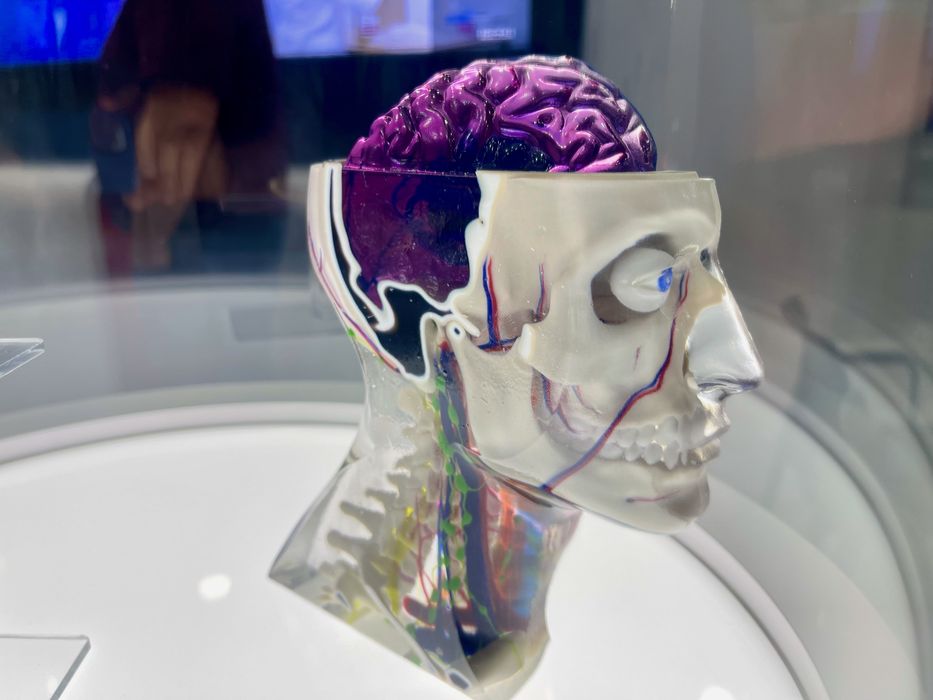

Another application area is healthcare, where anatomical models are becoming of increasing interest to practitioners.

These highly realistic prints can be used not only for education, but when combined with detailed 3D scans, can allow surgeons to develop complex surgical plans without affecting the patient.

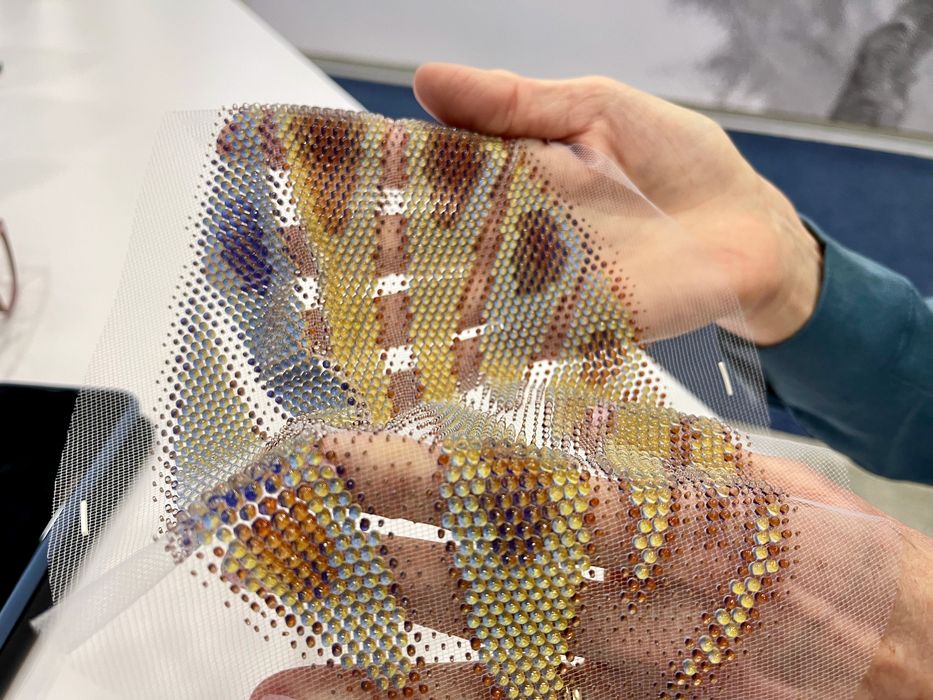

Finally, the third application of full color 3D printing seems to be textile printing. Here the full color print is embedded into fabric, forming an entirely new kind of clothing.

The examples shown above illustrates the technology, but doesn’t really show the potential. This is so new that it really hasn’t been properly explored by fashion designers yet.

Full color 3D printing has reached unparalleled levels of realism, but the applications for it are still fairly narrow.

Via Stratasys