Stratasys announced the acquisition of quality software startup Riven.

The Riven software will be directly integrated into Stratasys’ GrabCAD Print management platform, whereas previously it was one of their early software integration partners.

What is Riven? What does it do?

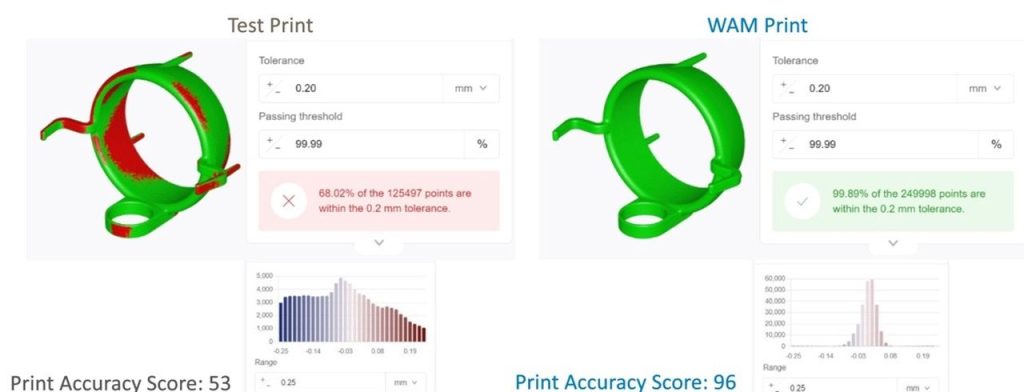

Riven is a cloud-based service that uses AI tools to increase part quality by examining actual prints and correcting their original CAD design to compensate.

Typically 3D prints do not emerge from the printer in exactly the form described by the CAD design file. The peculiarities of printer hardware tend to distort the physical prints in certain ways, leading to dimensional gaps between the desired and actual.

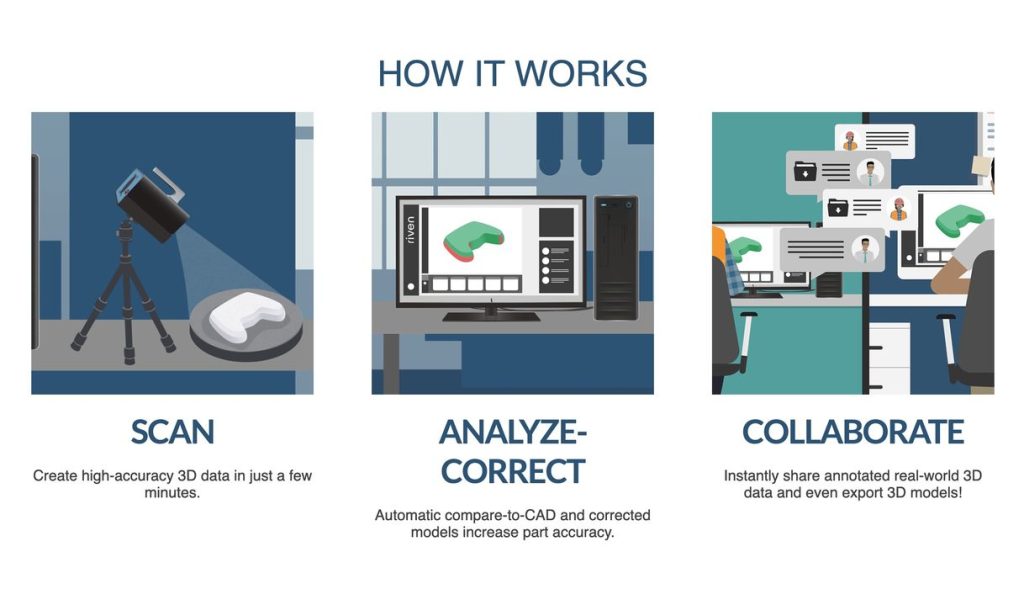

The process begins with a scan of a 3D printed sample part. The 3D scan is then compared to the CAD design by Riven’s cloud service to identify differences. These differences are then used to re-jig the original CAD design slightly so that the distortion actually places material where it is intended to be. The distortions are leveraged during the printing process to achieve better quality.

This effect is most prevalent in metal 3D printing, where the extreme heat required to fuse metal particles generates enormous thermal gradients that cause distortions, warping and even cracking in extreme cases. Considerable effort is typically done to engineer out these effects.

Stratasys explains how this will work:

“Riven’s cloud-based software helps customers quickly inspect, diagnose, and automatically correct deviations between CAD files and actual printed parts, resulting in more accurate parts at a lower overall cost. A new version in testing uses artificial intelligence to pre-adjust the models automatically. Parts inspection in particular can be a significant bottleneck in the production process, in many cases creating delays of weeks or months. By integrating Riven’s software into a closed-loop 3D printing process, Stratasys will be able to help its customers scale their shipments of 3D printed end-use parts while reducing waste through fewer iterations to improve sustainability.”

There’s more than just a quality benefit here.

Without advanced software assists, 3D printer operators typically iterate through prints to gradually tune out the distortions. This can be incredibly time consuming, expensive and wasteful. By using an AI-powered tool like Riven, it could be possible to short-circuit this workflow and save time and money, in addition to increasing part quality.

The acquisition covers “all intellectual property” of Riven, which includes their two main systems: Warp Adaptive Modeling (WAM) and Predictive WAM (PWAM), which perform the functions described above.

Terms of the acquisition were not announced by either company, but it appears that the founder of Riven, James Page, will now take on the role of Software VP at Stratasys, presumably looking after Riven’s tools within Stratasys. In addition, the Riven software team is to be absorbed by Stratasys’ Software business unit.

This is a good move by Stratasys, as it solidifies their hold on a critical function for 3D printing. In the very near future, the manufacturing needs of many companies will require near perfect parts, and software is required to achieve that. Riven will fill that need for Stratasys.

However, there is one question that occurred to me while reading through Riven’s material: much of their documentation seems focused on metal parts, which makes sense. That’s the area where quality is of most interest these days, as metal parts are typically for production use. It’s also where the best business case appears: metal 3D printing is really expensive, so reducing iterations would be very beneficial.

However, as of today Stratasys doesn’t really sell any metal 3D printing equipment. They offer FFF, PolyJet, SAF, P3 and SLA printing processes in their current line of equipment.

I’m now wondering if this acquisition is positioning Stratasys for a metal play of some form in the near future.