Stratasys announced sweeping upgrades to their GrabCAD software tool, specifically for managing fleets of 3D printers.

Stratasys has long been using GrabCAD as their platform for individual and workgroup 3D printer management, after their acquisition of GrabCAD way back in 2014.

Now the company has beefed up the functionality of GrabCAD in order to manage large numbers of networked 3D printers in factory configurations.

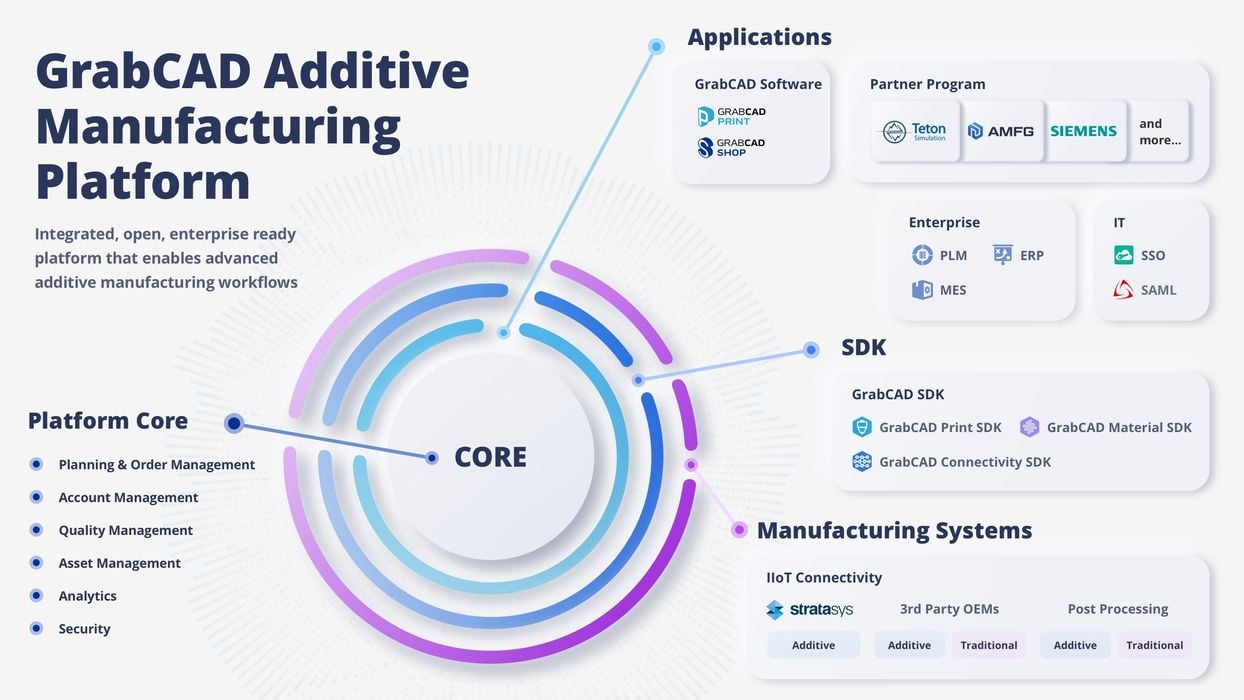

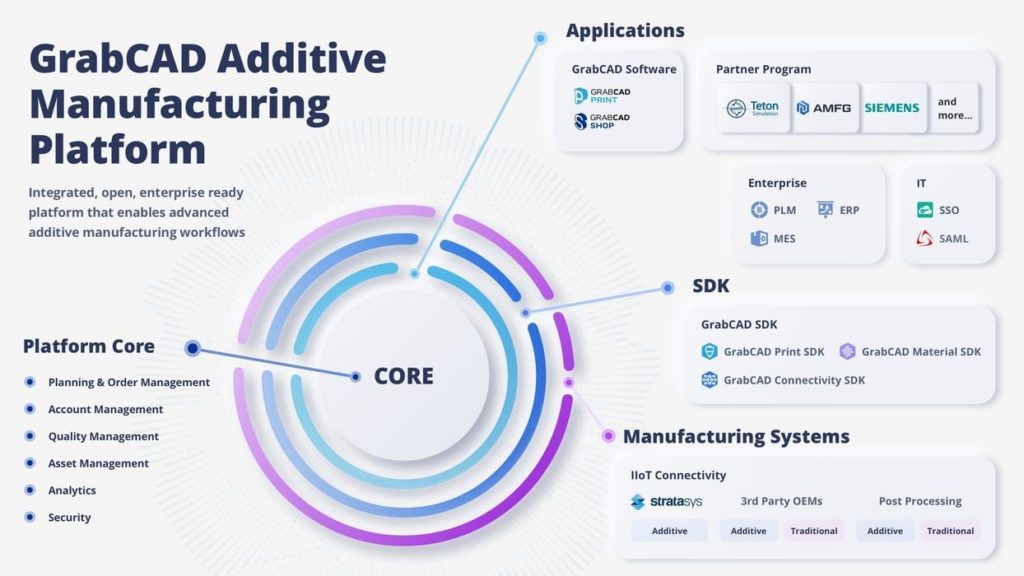

What’s changed? Take a look at these functional components of the latest GrabCAD:

- GrabCAD Print: Simplifies the workflow between Design for Additive Manufacturing (DfAM) and 3D print preparation. GrabCAD Print is CAD-agnostic, uses best-in-class security protocols, and is managed on the desktop or mobile.

- GrabCAD Shop: Cloud-based software-as-a-service (SaaS) work order management application that simplifies the 3D printing workflow. All orders are managed in one location and are easily assigned to all networked printers, including Stratasys and non-Stratasys systems.

- GrabCAD Print Manager: A new application that enables manufacturers to manage fleets of industrial 3D printers. GrabCAD Print Manager manage licenses to software and open material partners and provides customers the ability to view and manipulate production print schedules and view in-depth reports via desktop or mobile. Additional admin and access control are on the way with more details expected to be announced in early 2022.

- GrabCAD Software Development Kit (SDK): Industry 4.0-ready SDKs provide API’s, documentation, code samples and support integration with enterprise IT as well as third-party applications for account management, asset management, planning and order management, security, quality management, and analytics.

In addition, GrabCAD already integrates with a number of highly useful third-party tools, including those from AMFG and Teton Simulation.

Stratasys provided a statistical update on GrabCAD penetration, saying they now have more than 38,000 users controlling over 20,000 3D printers. They process an astonishing 35GB of data each and every day, demonstrating the extensive use of the system by Stratasys clients. In addition, they also said there are more than 100 developers working on GrabCAD.

Why this change?

I believe this change to GrabCAD is yet another step on Stratasys’ journey to the world of manufacturing. The company spent over 30 years providing essentially prototyping equipment and services, but after their key patents expired competition has been eating up that market segment.

To survive into the distant future, Stratasys has made a number of moves towards servicing the manufacturing industry. This is a very difficult strategy to execute, and Stratasys’ competitors will no doubt find it challenging to follow.

By entering the manufacturing market early, Stratasys hopes to secure a major portion of the business before others eventually arrive. And that market is truly immense, with many estimates at US$12T annually. Even a tiny slice of that market would be vastly larger than those served by current 3D printer manufacturers.

Stratasys’ long experience working with manufacturers puts them in an excellent position to achieve manufacturing success. It’s not just about the hardware; instead it’s a complete package including materials, certifications, service, finances, and, of course, software.

No 3D printer manufacturer will succeed in manufacturing unless they cover all the bases, and GrabCAD is one of the key elements required.

That’s what the new GrabCAD functions are all about: positioning for our mass customization future.

Via BusinessWire, Stratasys and GrabCAD