Stratasys announced two new partners to their GrabCAD Software Partner Program.

GrabCAD is the software platform that drives all Stratasys devices, providing direct connection with the equipment for control and monitoring purposes, as well as job preparation and tracking.

Stratasys smartly created a system development kit (SDK) to allow developers to easily integrate new tools into the GrabCAD environment. Use of the SDK is coordinated through the company’s GrabCAD Partner Program.

The two new partners will add interesting functionality to the system.

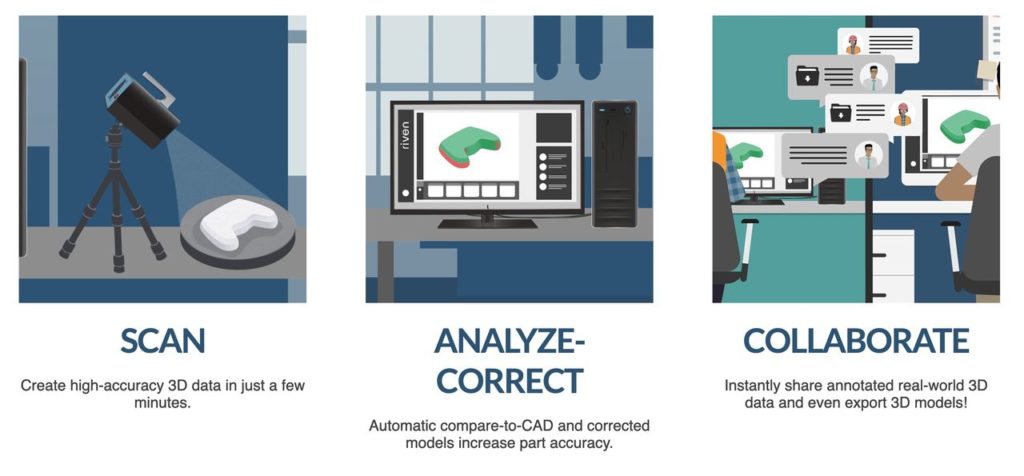

The first new partner is Riven, a cloud system that provides critical quality control in an additive manufacturing scenario. Their system involves scanning parts produced and validating them against the expectations of the original 3D model.

This can be leveraged in several ways. For example, freshly printed parts could be checked by Riven to ensure they’re sufficiently accurate to bother with expensive post processing steps. Another approach is to print a test part and determine the deviations from expectations, and then adjust the 3D model to compensate before reprinting.

The integration means that this type of functionality would be available seamlessly for those using Stratasys equipment and Riven.

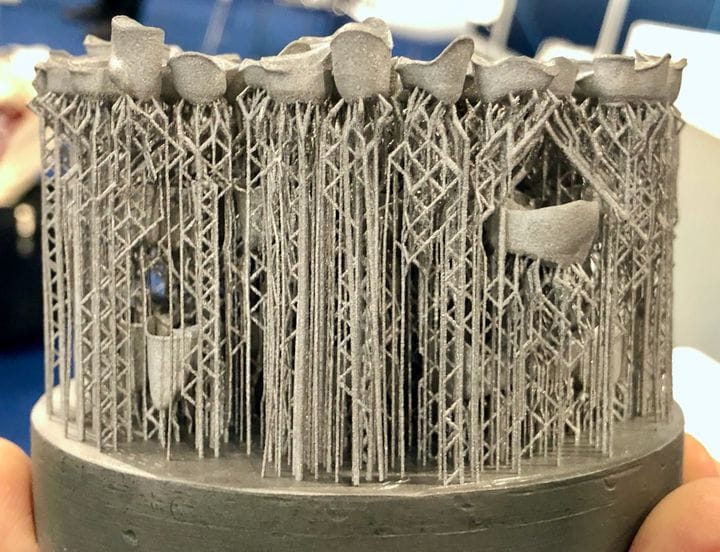

The second new partner is Oqton, which we’ve written about many times. The company produces a cloud-based manufacturing execution system that offers easy ability to implement new types of applications and advanced functionality. For example, we saw them generate previously unseen multi-layer support structures for metal 3D prints that allowed more dense part packing.

The integration with GrabCAD again means Oqton customers can directly work with the Stratasys equipment without much fuss.

There’s another interesting twist to this integration: Oqton was recently acquired by long-time Stratasys competitor 3D Systems, which has been busy integrating Oqton into their own systems.

It might seem strange for Stratasys to be integrating with a competitor’s product, but there’s method to this madness.

The old days of making walled gardens of 3D printers simply doesn’t work anymore. Today’s 3D printers are largely specialized and most operations would require equipment from several providers to get their work done.

To further complicate matters, there is a bit of a buying spree on these days among 3D printer manufacturers, so the equipment on the shop floor might tomorrow end up being provided by a different company. The same can be said of software driving this equipment. It’s a very fluid situation, especially given

The result is that major 3D printer manufacturers have to realize they cannot hold a monopoly in customer workplaces, and they have to recognize the presence of other equipment alongside their own. That recognition manifests as an integration capability that helps provide the customer with the potential of using a single method for using all of their equipment.

That’s the AM world we live in.