Charles R. Goulding and Preeti Sulibhavi examine the potential use of several forms of 3D printing in a new building project.

The recently announced Stony Brook Living Laboratory project is a US$700M, multidisciplinary initiative aimed at promoting sustainable development and environmental stewardship. 3D printing could be used in various aspects of the project. The campus, which will be on New York’s Manhattan Governors Island will be dedicated to solving the climate crisis we are facing in the form of severe weather among other natural disasters.

For example, 3D printing can be used to create prototypes and models of sustainable designs for buildings and infrastructure. It can also be used to create custom parts and components for renewable energy systems, such as wind turbines and solar panels. Additionally, 3D printing can be used to create educational tools and interactive exhibits for visitors to the Living Laboratory, helping to promote environmental awareness and sustainability.

The Living Laboratory Project will involve:

- An all-electric campus with all energy needs generated on-site

- Making the campus meet Living Building Challenge Standards

- New York City’s first commercial buildings utilizing mass timber

- Achieving zero-waste certification

- Climate-resilient building designs, achieving Waterfront Edge Design Guidelines certification

- A district geothermal and heat pump HVAC network with an estimated 70% reduction in energy use compared to other facilities of the same size

The Living Laboratory project on Governors Island is analogous to the Cornell Tech’s Graduate School and Research Center on Roosevelt Island in Manhattan.

3D printing technology allows for the creation of three-dimensional objects from a digital design file, which can be used to create models, prototypes, and even final products.

In the context of the Stony Brook Living Laboratory project, 3D printing can be used in a number of ways. For example, it could be used to create models of buildings, landscapes, or other features of the environment that are being studied. These models could be used to better understand how changes to the environment might affect different aspects of the ecosystem.

Stony Brook will work with city-based organizations in workforce training and educational programming for the Center. Stony Brook already has joined forces with Farmingdale State College to bring climate-related job training to Long Island, especially in wind energy technology.

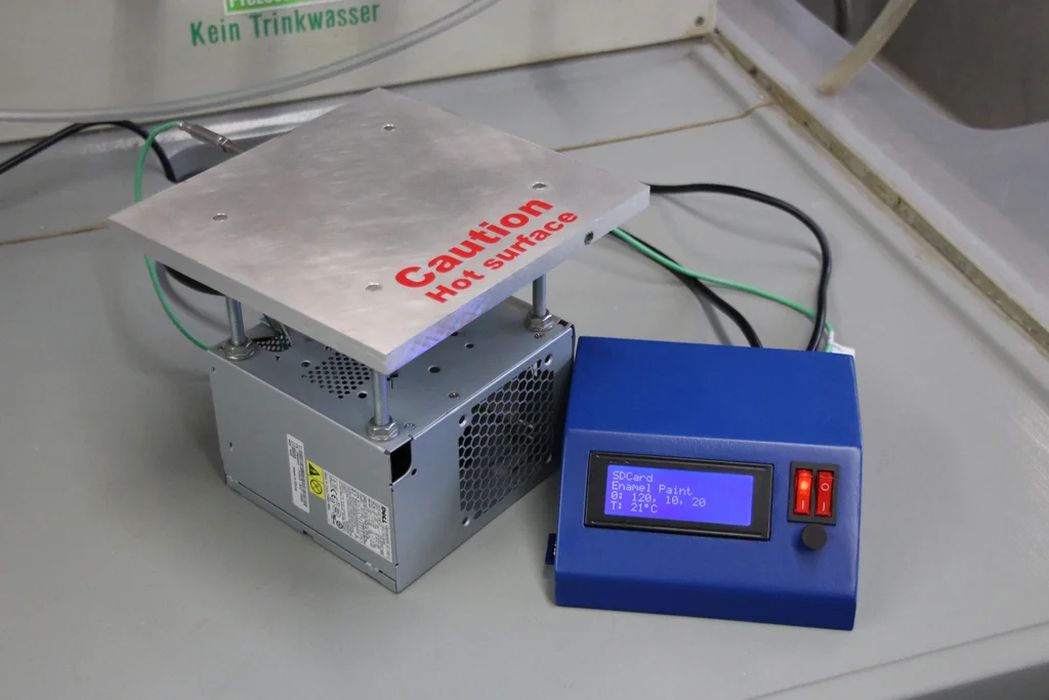

3D printing could also be used to create custom scientific equipment, such as sensors or data loggers, which could be used to collect data in the field. This could be particularly useful in situations where off-the-shelf equipment is not suitable or is too expensive. We have previously covered how 3D printing can be used to fabricate high-quality labware.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Overall, 3D printing can be a valuable tool in the Stony Brook Living Laboratory project, providing a flexible and cost-effective way to create custom objects and equipment for scientific research.