A Polish startup has developed an eco-friendly spool for 3D print material.

STEELTEK was started by Łukasz Łukasik in Kraków earlier this year, and their product is not 3D print material, but the spools on which filament can be stored.

Much has been said on the use of eco-friendly materials, and we’ve seen a number of initiatives to introduce recycled filament products, for example, or biodegradable materials. One of the most popular 3D print materials, PLA, while made from biological ingredients, is not practically biodegradable and often ends up in a landfill.

But while we fuss over the materials, there is also the matter of the spool holding the filament material. What is it made from? Is it recyclable? Is it biodegradable? How much energy was used to produce it?

STEELTEK hopes to solve these questions with a new line of 3D printer filament spools that all have notable environmentally-friendly profiles.

Why do this at all? Łukasik explains one of the reasons:

“STEELTEK pays a lot of attention to reducing the so-called carbon footprint – its products are characterized by a loss of -0.3 / -0.5 kg. To realize the importance of this factor, ones should understand that during the production of one spool of polycarbonate, very popular on the market (with an average weight of 250 g), over 1 kg of CO2 is emitted into the atmosphere – this is a greater mass of greenhouse gas than the amount of filament wound on this spool.”

This is an incredible statistic: the spool’s CO2 footprint is heavier than the material carried on the spool! Of course, the CO2 footprint of the material will also be significant, but this shows that if we ignore spools, we’re ignoring a significant CO2 generator.

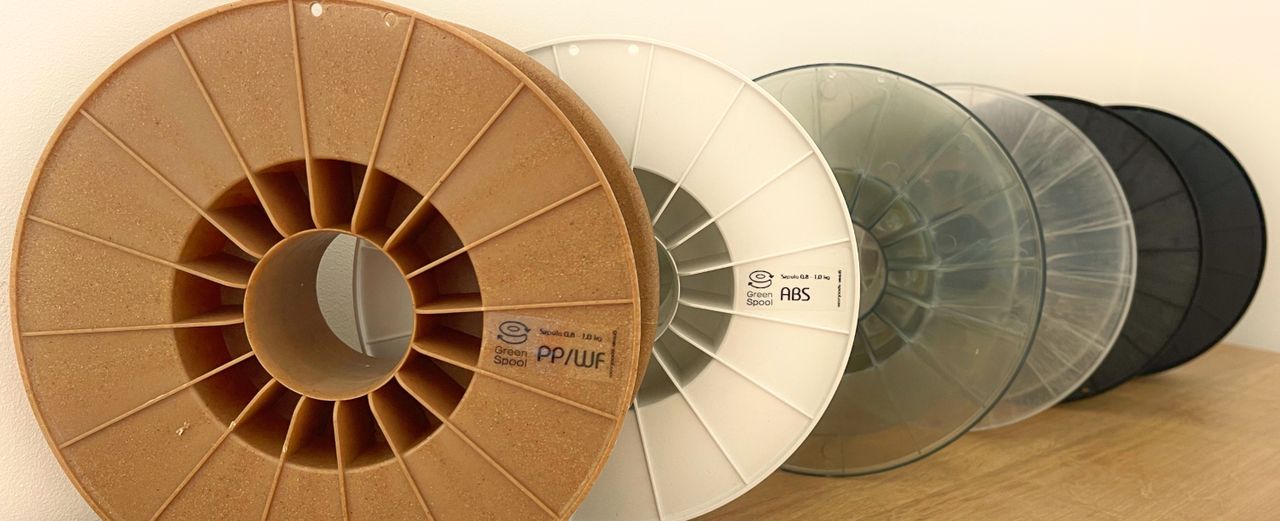

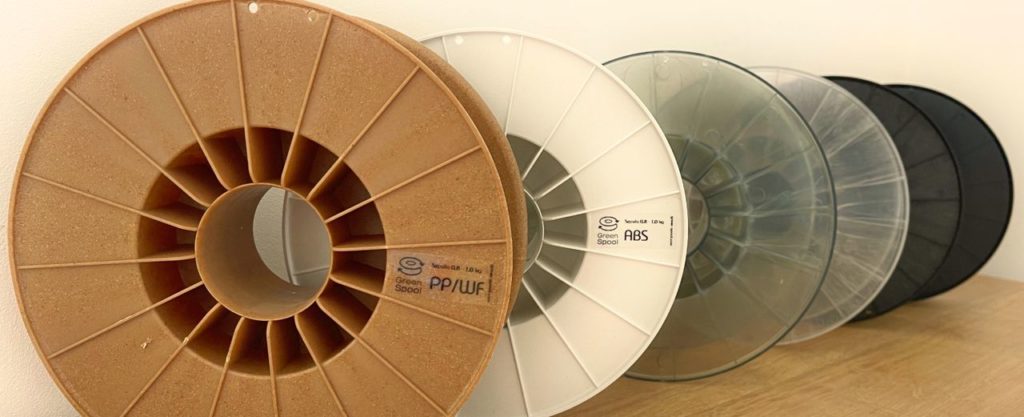

Today STEELTEK markets six different eco-friendly spool products:

- Green-Spool WOOD is a composite of recycled polypropylene and wood fibers

- Green-Spool TALK is a composite of recycled polypropylene and chalk

- Green-Spool PET being a recycled PET beverage bottles

- Green-Spool rABS being ABS recyclate

- Green-Spool rPC which is a recycled polycarbonate

- Green-Spool rHIPS which is a HIPS recyclate obtained from household appliances (e.g. inside refrigerators).

They have also redesigned the spool’s geometry to be fully functional, yet weigh 20% less than most other spools. The use of fibers also reduces the weight within that geometry further, leading to potential savings of CO2 and cash for shipping filament products.

What I find interesting about this product line is that it’s specifically based on particular recycled or sustainable material sources. But regardless of the source, each spool performs the same function: holding a coil of filament. We spend so much time discussing different 3D print materials for their engineering properties, but spools are spools, and it shouldn’t matter what they’re made from. So there’s really no excuse for not using an eco-friendly spool.

STEELTEK has designed the green spools to be used with “refill”-style filament, where the manufacturer ships only a coil of material, and the user must provide a spool for mounting.

While that’s one way to use these products, I suspect a better way is for 3D printer filament manufacturers to partner with STEELTEK to use eco-friendly spools for all filament products.

It turns out this may be happening. According to STEELTEK:

“The startup is currently conducting a series of advanced talks with potential partners from Europe and other regions around the world. The first filaments of well-known manufacturers will soon to be found on Green-Spool.”

We don’t know yet who these manufacturers might be, but I’m hoping other material producers shift their products to more eco-friendly alternatives.

Via STEELTEK