I had a chat with Luke Taylor of Polymaker about the latest developments from the company.

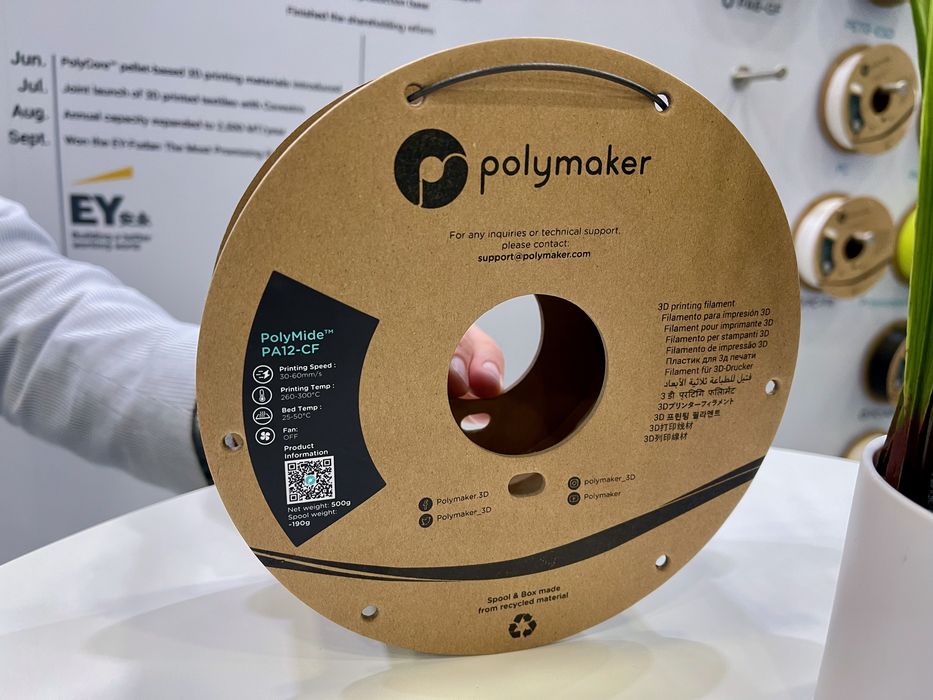

Polymaker is one of a few producers of 3D printer filament that continue to introduce key innovations year after year, such as their PA12-CF material shown at top. As such, they are very aware of the current state of the filament industry, and I was able to find out about recent developments at the company.

Polymaker is based in China, but has been expanding worldwide for some time. Recently they opened up a warehouse in Texas, which will make shipments to North American destinations far more straightforward. Filament is a product that tends to be produced regionally because the costs of shipping can tip the unit price in the wrong direction if coming from distant manufacturing locations. It looks like Polymaker has solved that issue for North America, and that’s particularly important for our supply chain-challenged world.

Taylor added that the company now has a growing team in the EU and United States, including 40 in research & development.

Their new PolyMide PA12-CF at top is interesting because they’ve introduced a breakaway support material for it, PolySupport that can come in different colors for easier seeing against dark CF parts. Imagine how easy it would be to see this near-fluorescent yellow support material on a black CF part.

Polymaker has had a notable emphasis on being ecofriendly as much as possible. One of their innovations has been the use of cardboard spools. While this has been done in the past, it has normally been done with typical cardboard that bends and rips. Polymaker’s cardboard is a much harder material that they die cut. It’s so strong that the spools roll very easily, and should be an inspiration to other filament manufacturers that continue to use eco-unfriendly plastic spools.

Taylor explained there has been a significant shift in demand for 3D printer material. Previously Polymaker’s sales were about 60% to industrial users, with only 40% to consumers. However, in the past couple of years that has reversed and is now 60-40 for consumers over industrial. This is a bit of a shock, as industrial usage was expected to outstrip consumer use in the long run. Taylor suggests this phenomenon might be based on the emergence of inexpensive consumer desktop 3D printers that are now being produced in vast quantities.

Taylor explained that Polymaker has had great success with their PolyLite and PolyTerra line, which is a PLA that provides an attractive matte surface in several colors, including the pink material we’ve tested above. Taylor said they believe many ETSY stores offering 3D printed products tend to use PolyTerra for their production.

By the way, PolyTerra has an interesting feature: for every spool of PolyTerra sold, Polymaker will arrange for a tree to be planted in the region where the sale occurred. They even have a live counter of trees planted thus far, and it’s now dangerously close to 200,000 trees.

While there has always been tremendous interest in PLA materials, Taylor said their company saw a surge of PETG use after the pandemic. This could be due to the use of the material by pop-ups producing emergency pandemic parts, as Polymaker apparently shipped some 500kg to those who wanted.

Taylor reports that the use of ABS is still increasing somehow, even though it really isn’t a terrific 3D print material. However, Taylor also said that ASA is “exploding”. ASA is like a “better ABS” because it offers UV resistance and thus can be used for outdoor parts.

I asked Taylor about the difference in demand for 2.85mm vs 1.75mm filament diameters. The latter seems destined for eventual dominance, but Taylor said their sales of 2.85mm filament have “flatlined”, whereas the 1.75mm filament sales are growing.

We can only hope.

In the meantime, be sure to check out Polymaker’s incredible array of 3D print material options.

Via Polymaker