Polyga is offering powerful software that can be used with self-built 3D scanners.

Wait, what? People build their own 3D scanners? What is this all about?

Polyga is a Vancouver-based company that produces stationary and handheld 3D scanners of professional quality, and they’ve been doing so for over ten years. In addition, they also market plugins and utilities that aid the reverse engineering process often used with 3D scanning activity.

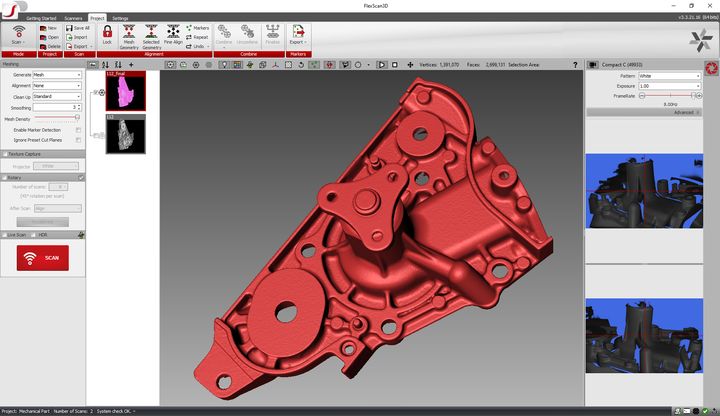

But one product they offer seems quite unusual. It’s called “FlexScan”, and they describe it as:

“The powerful 3D scanning software empowers makers, students, researchers, and entrepreneurs to build an affordable structured-light 3D scanner.”

This software is essentially the same software that’s normally bundled with their 3D scanning hardware — all 3D scanners depend greatly on associated software to operate.

Selling the software separate from the hardware is, I believe, unique in the industry. I am not aware of any other 3D scanning vendor that sells software separately. Some may offer their software free to download, but it only works with the targeted hardware.

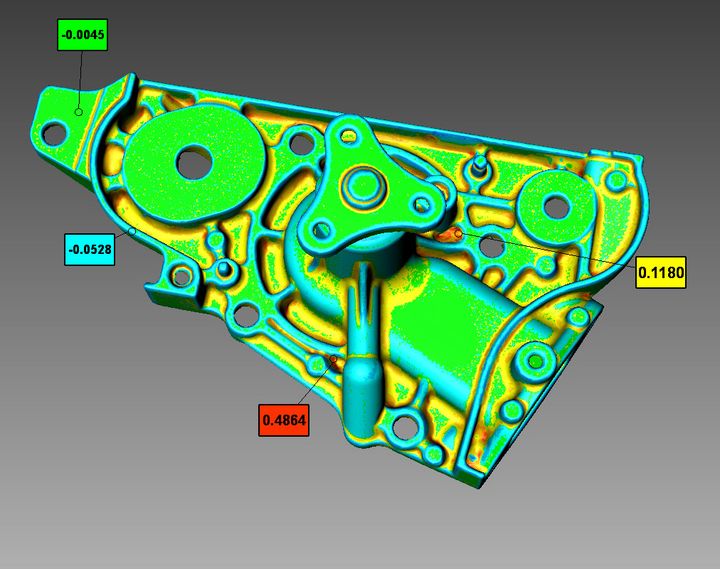

If you’re building a 3D scanner, why do you need software? It turns out that the most important part of any 3D scanner is actually the software. The hardware typically collects a series of images, and the software interprets them, transforming the information into actual 3D models.

That processing includes mapping the 2D images to 3D positions, producing a point cloud. The point cloud then has to be knitted together into a 3D mesh, and then the mesh itself has to be cleaned up. There’s quite a bit happening behind the scenes in 3D scanning software.

This is the case regardless of the type of 3D scanning taking place: whether it’s color images, structured light patterns or depth maps, they are all just types of images that require some kind of processing.

What I’m trying to say here is that building the hardware might be less complex than the processing software. In other words, building your own 3D scanner might be achievable by more people than you’d think.

But they’d need software with that hardware. That’s where Polyga’s FlexScan comes in.

Polyga explains:

“With FlexScan3D, you’ve got the software component covered to get you started on building a custom 3D scanner. All you have to do is source your own hardware components. The 3D scanning software interfaces with a recommended list of readily available off-the-shelf machine vision cameras, lenses, and HDMI projectors.”

Polyga offers a non-commercial license for FlexScan for only US$500, which is an incredibly good price for such powerful software. For commercial use, the software license is still a reasonable US$2,000, and the company offers monthly subscription plans as well.

You might be thinking, “Why build 3D scanner hardware when you could just buy one?”

The answer is hidden in the name of the product: FlexScan. This is a “flexible” solution that allows you to build ANY kind of 3D scanner hardware you’d like. For example, perhaps you need a customized quality control inspection station and it requires the ability to 3D scan parts as they come by. With FlexScan, you might be able to build one.

Other potential applications could include mobile 3D scanners, scanners embedded on drones or robots, body scanning systems and much more.

There are no doubt all kinds of alternative 3D scanning setups that could be implemented with FlexScan, and you’d need only to design and build the hardware to get going.

This isn’t as crazy an idea as I originally thought!

Via Polyga