Snapmaker announced a series of new products and hardware.

The company emerged on the scene a few years ago with a hybrid device that not only 3D printed, but also performed CNC milling and laser engraving. The idea was that all these functions can re-use the same motion system, and all that’s required is a tool change.

Their concept was quite successful, and their first products garnered a huge number of buyers. Since then they’ve continued on to improve their technology and release upgraded products.

Currently their flagship device is the Snapmaker Artisan device, which is also a hybrid.

However, the company announced several new products today.

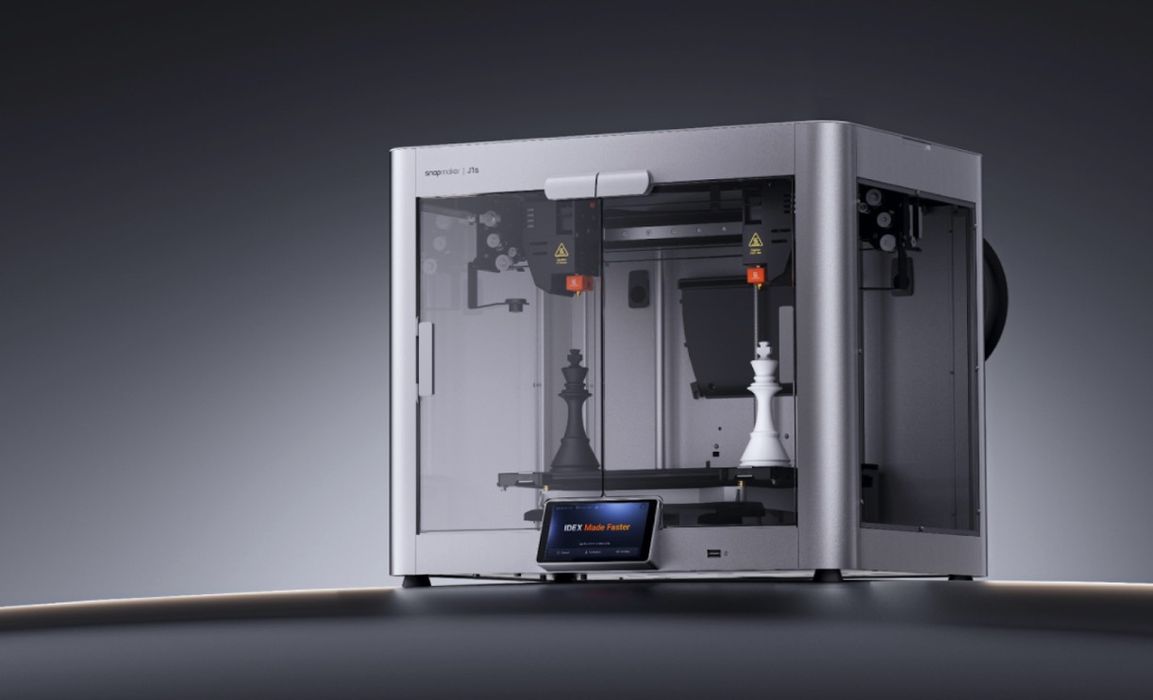

Snapmaker J1s IDEX 3D Printer

The most notable announcement is the new J1s 3D printer. This is a follow-on from last year’s J1 system, which introduced the IDEX extrusion concept to their product line.

IDEX, or “InDependent Extrusion”, allows for dual printheads that can move independently of each other. This allows some very interesting print modes such as:

- Duplicate: print two items at the same time beside each other in the time it takes to complete one print

- Mirror: print “mirror” copies of an object, a left and right version, perhaps

I’m waiting for a 3D printer manufacturer to figure out how to implement a “dual build” mode, where both toolheads can work on the same single print simultaneously — without crashing into each other. Snapmaker doesn’t have this yet, either, but I am still hopeful.

The J1s is also a high speed 3D printer, offering print speeds up to 350mm/s, far faster than the more typical 40-60mm/s seen on older devices. This allows production of larger objects in record time.

One of the improvements on the J1s model is a beefed up cooling system. When printing very fast there is less time for the previous layers to cool, and it’s possible for “slumps” to occur when extruding on a soft prior layer. To counteract this effect, the J1s has added new cooling ducts that completely surround the extrusion area.

This feature should much more rapidly cool extruded material, particularly low-temperature PLA, and result in not only more precise structures, but improved print reliability. Snapmaker explains:

“It comes with print cooling fans not only under the nozzles but also at the back panel. With a narrow fan duct blasting a wide area with air, the print cooling fan at the back can further cool your prints during high speed printing and lower the ambient temperature when printing materials like PLA.”

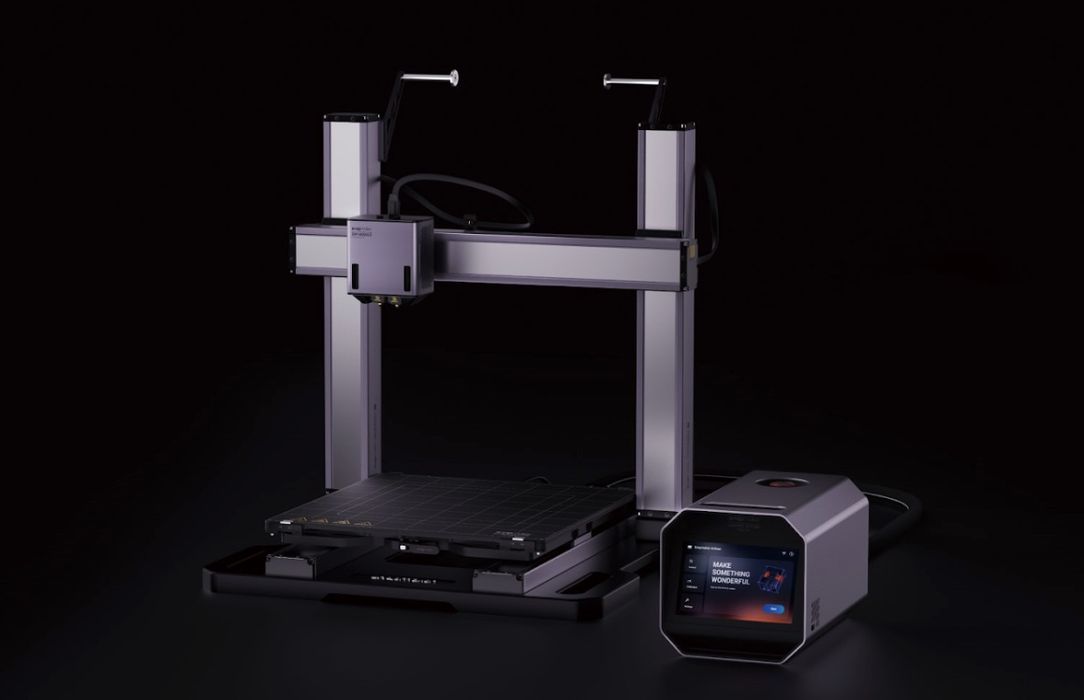

Snapmaker Artisan 3D Printer

In addition to the J1s, Snapmaker also announced the Artisan 3D printer.

Hold on, isn’t that their current hybrid product? Nope, here they’ve removed the extra toolheads and produced a 3D printer that is basically an Artisan device that only 3D prints. This suggests they have received enquiries about this option from folks who like how the Artisan operates as a 3D printer. It could also open up more sales possibilities, as some buyers don’t require laser or milling functions.

Finally, they’ve introduced an upgrade kit for their earlier Snapmaker 2.0 hybrid system to allow for much easier tool swaps.

Via Snapmaker