There’s news from ValCUN, makers of a very unusual metal 3D printer.

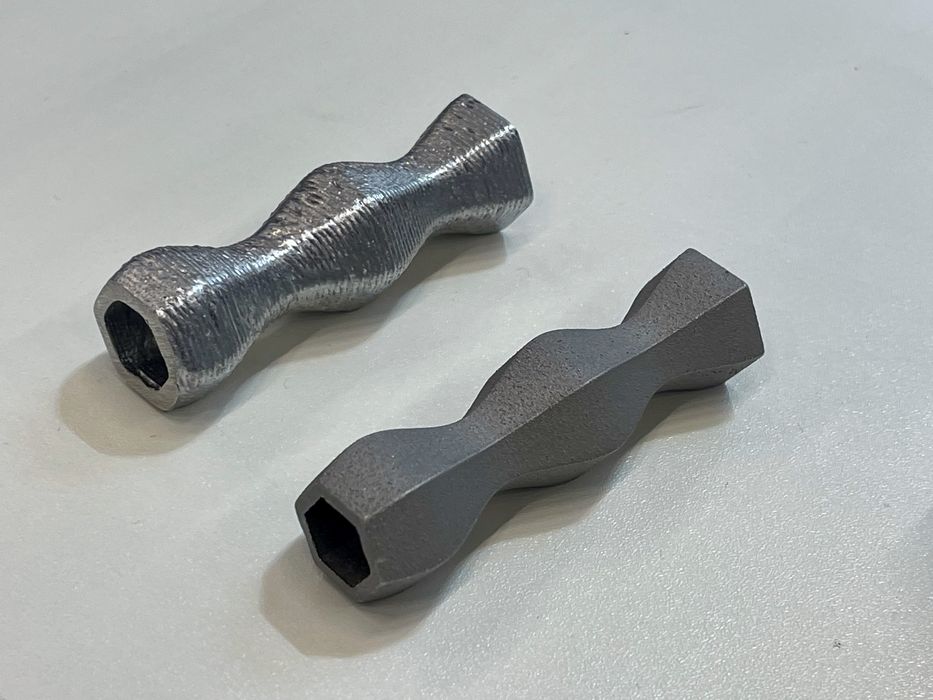

ValCUN first appeared in our pages back in 2019, when they announced plans for developing their liquid metal extrusion system. Last year at Formnext, we had a discussion with them about their system and examined some very competent print samples.

For those not familiar with ValCUN, their system accepts aluminum: any kind of aluminum, including low cost pellets, powder, scraps, ingots, etc. These are fed through the system to a ceramic nozzle and hot end, where heat of approximately 800C melts the metal. The liquid metal comes out of the nozzle and immediately freezes solid. By moving the toolhead around in 3D space, they can quickly build solid aluminum objects.

Because of the innovative use of raw metal inputs, ValCUN said the cost to run their system can be 75-90% less expensive than with conventional LPBF metal 3D printers.

When you first hear of this approach, you may be skeptical, as the liquid aluminum would simply pour out of the nozzle and form a puddle. But it turns out ValCUN has developed some very sophisticated technology that leverages surface tension and precision temperature control to ensure the metal solidifies exactly where it’s supposed to be. One key part of the technology is apparently the use of argon gas to form a curtain around the extrusion.

ValCUN calls this technology “Molten Metal Deposition”, or “MMD”. It’s very similar to FFF, yet uses metal and far higher temperatures. As you might expect, the rest of the system is somewhat similar to FFF systems.

They say that while they’re currently focusing on aluminum metal, their toolhead is fully capable of handling a variety of other metals. It should be quite interesting to watch them expand their portfolio in the future.

When we last spoke with them they were still developing their system, which is now called the “Minerva Printer”. This system is to be publicly unveiled at Formnext in only a couple of weeks.

The news this week is that they’ve actually sold their first unit to a customer. The customer is Belgian innovation center Sirris. Sirris is a non-profit that assists industry in technological innovations. They operate a series of industrial labs that works with companies to develop new manufacturing approaches.

This is a key sale for ValCUN, and not only because it’s their first. By engaging with Sirris, they will almost certainly gain wide exposure to a number of large companies through the work of the innovation center. Some of those exposed will no doubt consider acquiring Minerva gear from ValCUN in the future.

We’ll be watching ValCUN’s progress.

Via ValCUN