Charles R. Goulding and Preeti Sulibhavi look at the implications to 3D printing after a recent corporate merger.

In 2015 Merck KGaA, a German big pharma company, acquired Sigma-Aldrich for US$17B. Previously, in 2010, Merck KGaA, had acquired Millipore for US$7B.

With all the specialization each company brings to the table, this mega-merger of life science giants presents tremendous opportunities for the 3D printing industry.

Sigma-Aldrich

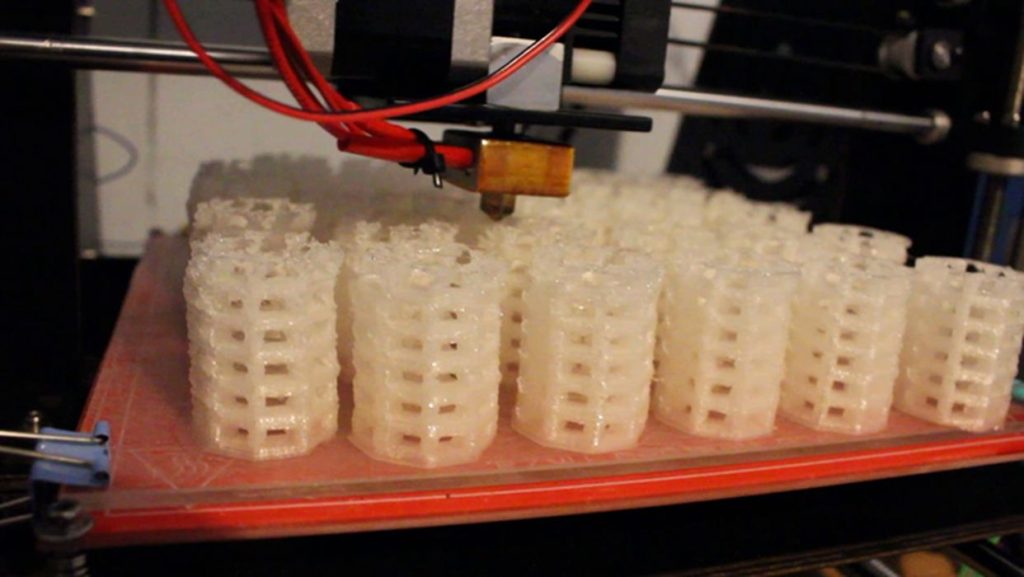

Sigma-Aldrich itself is a leader in the growing bioink industry. While traditional 3D printing utilizes basic polymer, metal and ceramic materials, bioink is a material that can be used to 3D print live tissue or organic material compatible with live tissue.

Often, these inks are composed of bioengineered organisms or cells, along with additional materials, that can be used to form the material. This “ink” can be extruded much like other 3D printing materials into filaments that retain shape. However, extensive work must be done for each bioink to ensure it maintains the necessary physical properties required for 3D printing. This is caused by the sensitivity bioinks often exhibit with normal 3D printing processing conditions, making them more difficult to use.

While 3D printing is often most associated with ceramics, polymers, and metals that are used to additively manufacture components, many scientists and researchers have been looking into unique and innovative avenues for 3D printing. This is often referred to as bioprinting. One notable area of research is programmable microbial ink, which uses living organisms to allow for 3D printed structures to perform functions previously unavailable. Prior to the merger, Sigma-Aldrich specialized in such products.

Millipore

MilliporeSigma is big in the filtration industry. This includes filtration for bioprocessing, concentration filters, filter paper, laboratory filter holders, filter membranes, syringe filters, and vacuum filters.

Filtration for bioprocessing, specifically, involves filtration-based solutions for DNA, RNA, and debris removal to help pharma manufacturers produce high-quality and pure biopharmaceutical products.

Merck KGaA

Merck KGaA has been using 3D printing primarily for packaging and labeling purposes. The German company has been making labels using 3D printers that have a touch and feel, raised effect referred to as VE3D technology. This special technology can assist patients in identifying their medications more easily, especially those with visual or reading disabilities.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The merger of all three, life science/med-tech giants is good news for the 3D printing industry. With the strong foundation Merck can provide in processes and protocols, the 3D printing that is currently taking place at MilliporeSigma can now grow limitlessly.