What does the investment in MakerVerse’s digital platform mean for Siemens Energy?

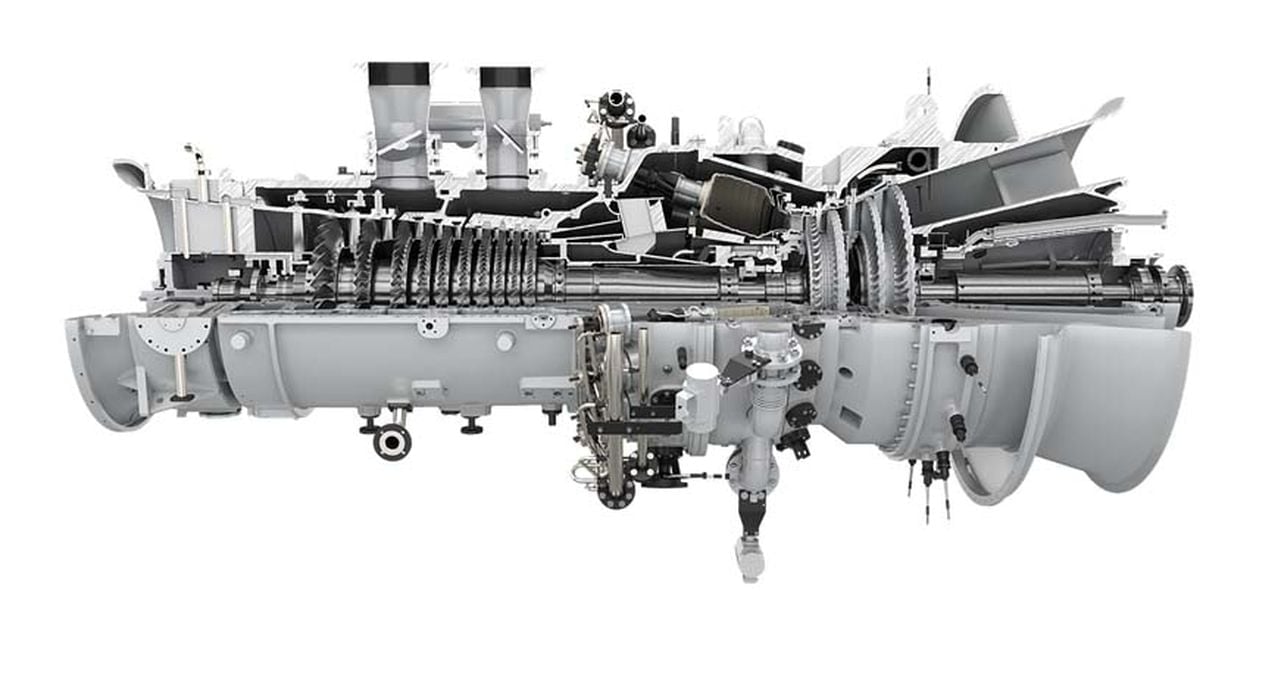

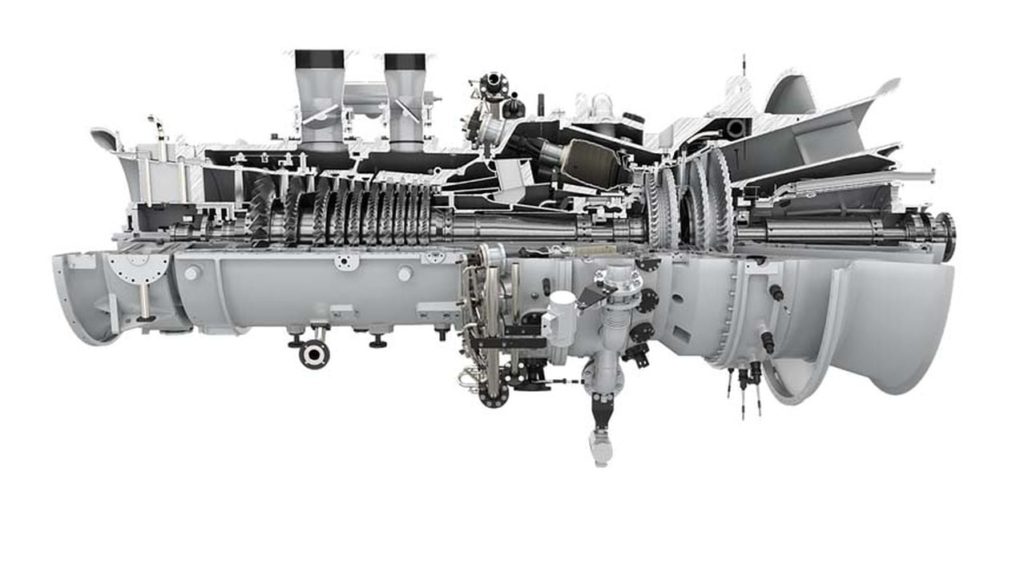

Siemens Energy has embraced additive manufacturing for its global operations lately, including projects such as prototyping and spare parts production. The company boasts one of the largest fleets of 3D printers in the world, deploying the technology to manufacture gas turbine parts and repair complex components like wind turbine blades. Siemens Energy claims that additive manufacturing is vital in their mission to improve energy efficiency, reduce material waste and cut carbon emissions.

Continuing their aggressive movement into the additive manufacturing world, Siemens Energy has made an investment in MakerVerse, a digital platform connecting industrial clients with additive manufacturing centers and suppliers. Siemens Energy has partnered with ZEISS and venture capital firms, including 9.5 Ventures, to give MakerVerse the financial support needed to continue growing their platform and expanding their footprint to multiple industries.

The long-term vision for the MakerVerse platform is to create a fulfillment platform that connects industrial players to additive manufacturing suppliers dispersed around the world. This will essentially allow a global company like Siemens Energy to connect with an additive manufacturing operation near a key project site and produce spare parts or develop prototypes without having to outfit their own operation.

On-demand additive manufacturing helps make the technology more accessible for companies that don’t need a dedicated additive manufacturing center of their own, but would still like access to the technology. Large companies are also afforded the ability to get parts to a remote project located far from their central manufacturing hub.

MakerVerse’s platform currently features polymer and metal additive manufacturing services, with a hope to expand further into CNC, sheet metal and injection molding. The platform works simply and intuitively, allowing a designer to upload a CAD or STL file of a part and select specifications like material and post-processing. After receiving a quote and placing an order, the designer is matched with a partner in MakerVerse’s production network.

The entire manufacturing, quality assurance and shipping process is housed within MakerVerse’s on-demand platform, making it a fully streamlined, one-stop shopping solution for part production.

Producers and makers alike stand to benefit from wider adoption of on-demand additive manufacturing. Makers get industrial-grade quality and access to additive manufacturing services like rapid prototyping without having to make a large investment in 3D printing hardware of their own.

All suppliers in the MakerVerse network are prequalified and trusted, and the platform offers supplier quality management. MakerVerse also features built-in artificial intelligence that provides design feedback based on manufacturability, along with advice on selecting the right technology and material set.

For producers, MakerVerse offers expanded customer reach and an opportunity to work with clients from different industries around the world. The platform is also designed to reduce operational costs by providing assistance with digital sales and marketing. Joining the MakerVerse network is free, and no long-term commitment is required.

Read more at ENGINEERING.com