Hymer uses the Siemens Xcelerator software portfolio and BASF new materials to reimagine motor homes.

Hymer, a German-based pioneer of RV manufacturing, is embracing the latest software, technology and materials to create the motor vehicle of the future. The company announced a partnership with BASF in 2019 to create the VisionVenture concept vehicle, producing a new category of RVs.

An innovator in the market since 1956, Hymer is heeding the call of a changing industry. RVing is no longer just a way to skip town and enjoy the outdoors. With Wi-Fi all around and a housing market unsuitable for buyers, a new generation of consumers is turning RVs into homes. The market itself is expected to have a global 7 percent compound annual growth rate (CAGR) increase and is expected to reach $80 billion by 2027.

Hymer’s concept vehicle aims to break the mold of RVs and provide a glimpse into what luxury living on the road might be like in the future.

“With the VisionVenture, we are breaking completely new ground in terms of design, self-sufficiency and lightweight construction,” said Christian Bauer, Hymer chairman of the management board. “A major source of inspiration for this project was the camper community, who have given us new impetus with their creative ideas and DIY conversions. Of the numerous innovative and extremely customer-oriented solutions, we will certainly be able to use some elements in our production vehicles in the not-too-distant future.”

Luxury on Wheels

The VisionVenture concept starts with a Mercedes Sprinter chassis, which provides higher clearance. Hymer then worked with BASF to determine which materials would be best for this new four-wheel drive vehicle. The companies decided on 20 materials that would make the vehicle lightweight and more sustainable yet luxurious.

One of those was BASF’s Chromacool technology, which regulates the vehicle temperature and is energy efficient. This material, which reduces the temperature surface by 20 °C, allowed Hymer to use a dark-green color instead of the traditional white and light grays often used for RVs to help them stay cool.

The VisionVenture features a pop-up roof that opens in 60 seconds. This insulated, honeycomb-like structure has 7-centimeter-thick walls and includes a photovoltaic system on the roof. The pillows and mattress are fused modern materials, providing a memory-foam feel while staying cool thanks to BASF’s Elasticoat Spraygel. While the vehicle still features natural materials, such as bamboo, leather and wood, BASF’s Veneo Slate was chosen to create the look of stone without the weight. This flexible material is only 1 mm tall.

While traversing uneven terrain or paved roads, minimizing noise has become a must for modern-day comfort. Hymer and BASF worked to create a custom noise, vibration, harshness (NVH) package. It features Cellastro, a microcellular and compact polyurethane that works to minimize vibrations and noise in the vehicle’s chassis, drive and interior.

A luxury vehicle, of course, needs to have luxury finishes. The design team determined that Haptex would provide a cozy and sophisticated interior. This polyurethane is a soft imitation leather that is available in different textures and colors. As for lighting, the team opted for two pendant lights with diffusers made of Ultramid Vision, a translucent material that is chemical resistant and scratch proof.

3D printing was a modern technology the design team wanted to incorporate into the vehicle. More than 100 components were chosen to be 3D printed for both the interior and exterior, including the wheel arch linings. Using the latest 3D printing materials available would enable the team to print durable, rubber-like parts where needed and still do it with the least-cost production method.

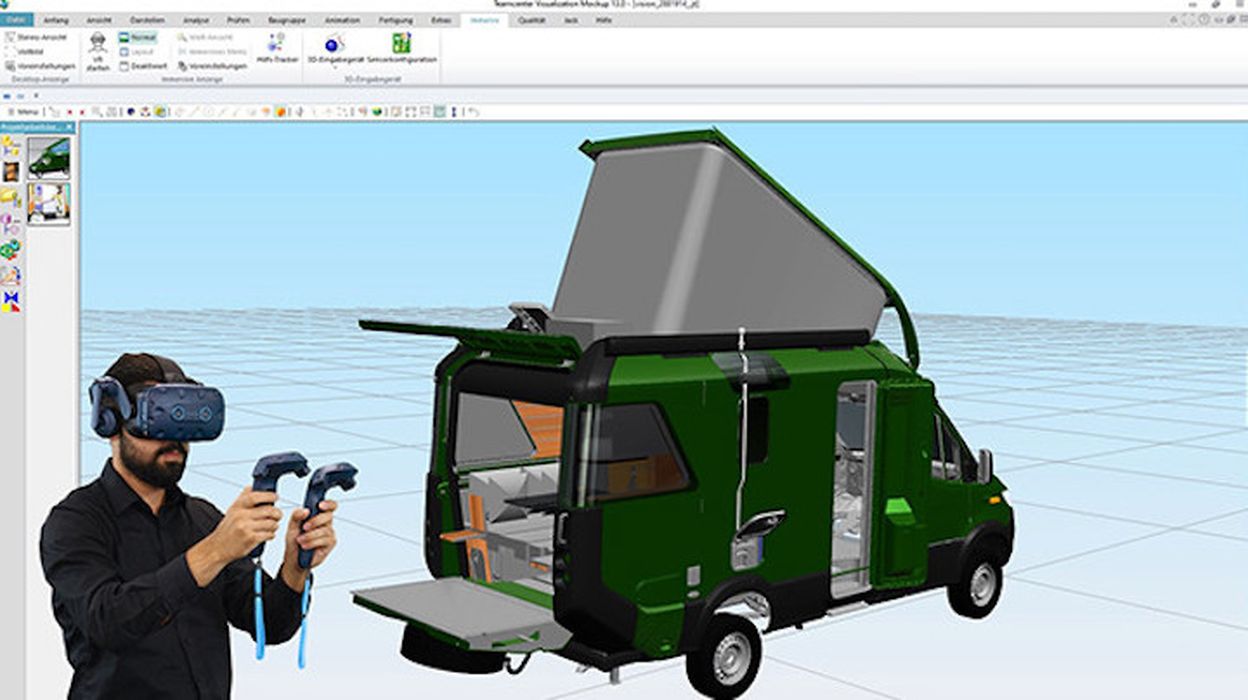

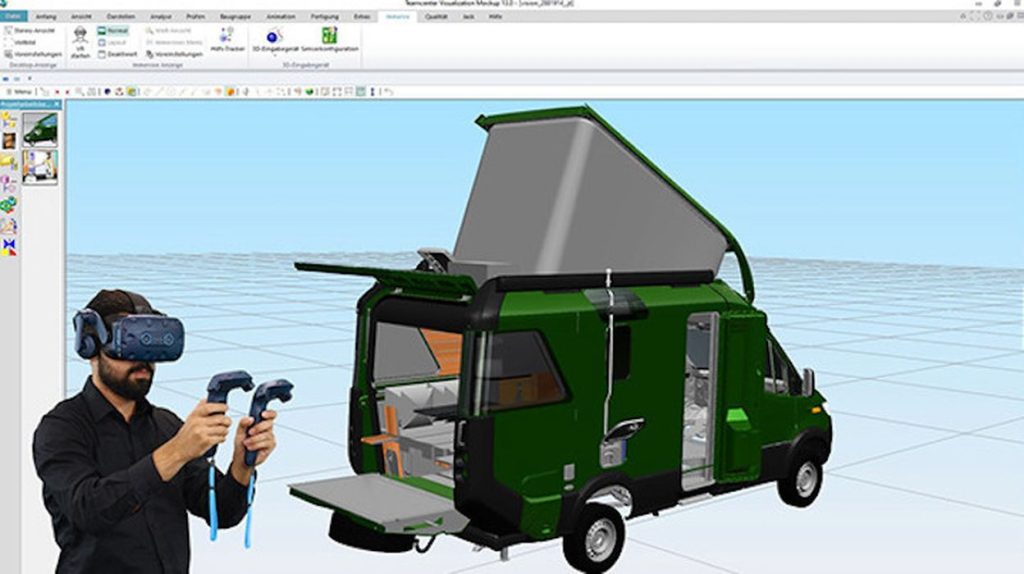

With the materials selected and the concept in place, the next step was bringing everything together in the most efficient way possible.

Read the rest at ENGINEERING.com