Carbon fiber is a more frequently seen material in 3D printing, but should it be in all materials?

I know what you’re thinking: this writer is off his rocker, and maybe you’re correct. But hear me out, there may be good reasons to do this.

Carbon fiber filaments are actually not made of carbon fiber. They are a combination of a polymer, often PA, PC or PETG, that is reinforced by tiny segments of chopped carbon fiber. These small bits act as “bricks” in the “mortar” and cause the resulting print to be far stronger than it would otherwise be with just a polymer material.

Note that the chopped carbon fiber approach is quite different than the much more rare continuous carbon fiber systems. These literally have a spool of carbon fiber, which is woven into the print as it proceeds. This provides the prints with extreme strength, even rivaling or exceeding that of metal parts, making “CCF” applicable for industrial applications to replace heavy metal parts.

Chopped carbon fiber filaments are widely available these days and can be used on most 3D printers, so long as they have an upgraded extrusion system that has hardened components to withstand the abrasion from passing carbon fiber bits. Standard brass nozzles, for example, can be ruined through erosion of only a spool or two of CF material.

Let’s assume 3D printers have these hardened components and they are able to freely 3D print CF materials.

There are two big advantages with CF material over “normal” 3D print materials.

The first is obviously part strength, as described above. You might think that the added CF strength might be applicable to only the parts that need it, but I have another thought.

All 3D printed parts deserve to have added strength. There have been many times where I’ve 3D printed a small decorative item, only to drop it on the floor and have it break. Those were parts that weren’t designed for heavy use, yet had to endure impacts anyway. I see every part gaining something from use of CF.

But there’s another hidden benefit to CF materials.

Carbon fiber turns out to be an outstanding conductor of heat and electricity. This means that as the print proceeds, the heat from the nozzle and fresh material will more easily traverse through the print, helped by the carbon fiber.

Why is this a good thing? It’s because of warping, the bane of 3D printer operators.

Warping occurs when the thermal difference between layers of a print are so extreme that the part deforms and pulls up off the print bed. This can result in a catastrophic print failure.

The problem is that while the bottom of the print is heated, and the top is hot from fresh extrusions, the middle is cold. Cold material shrinks, and that’s what causes the print to curl up.

What if the CF material was able to conduct more heat through that middle section? The heat would more easily transfer from the heated print plate at the bottom and the fresh hot extrusions at the top.

The result could be more reliable (and strong) 3D prints.

Everyone wants those attributes, so it would seem a natural step to make CF material a default for most FFF 3D printers, wouldn’t it?

There are a couple of downsides, however.

First, CF material is more expensive, sometimes much more expensive. However, if CF material was a default, then we’d see the price drop significantly due to economies of scale. There would also be savings in that there would be fewer print failures that completely waste material. Could this break even at some point? Perhaps.

Secondly, 3D printers would be very slightly more expensive due to the addition of CF-compatible components. However, this would be a relatively small cost and over time economies of scale would catch up.

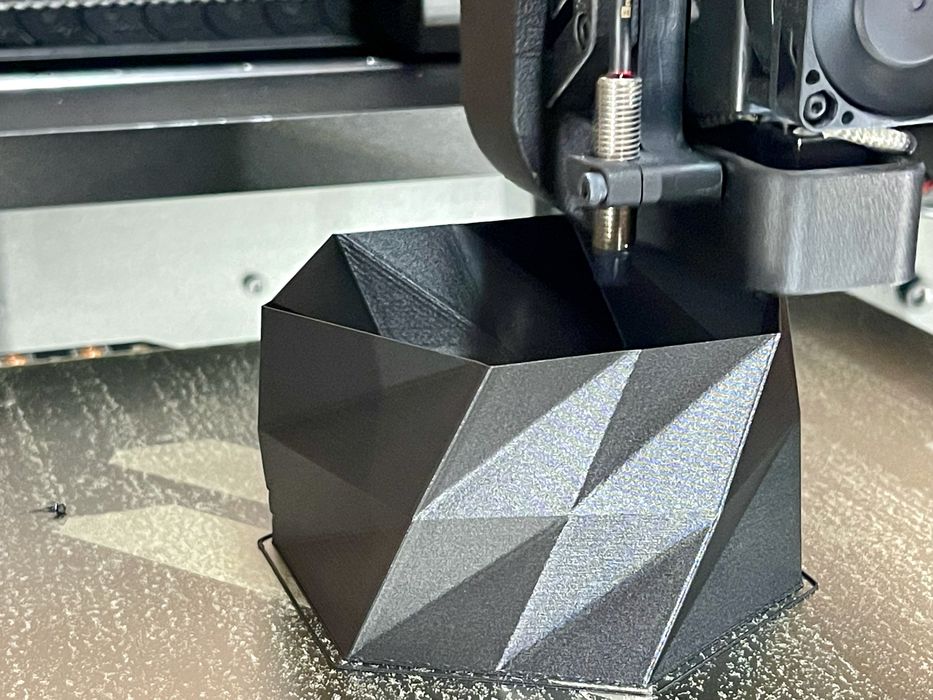

Finally, and this may be the biggest issue, is that CF material is essentially black in color. There is no white or colored CF filament, because carbon is black. I see no way around this, and a CF material default would cut off the use of the wide spectrum of terrific 3D print filament colors that has recently emerged.

What do you think? Should CF become a default material for FFF 3D printers? Or should all 3D printers be naturally able to use it without the need for upgrades?