You just received a brand new desktop 3D printer. What should you NOT do?

It’s that time of year when huge sales of inexpensive desktop 3D printers arrive in people’s homes, often for the very first time.

Yes, it’s an exciting moment: you now have the power to build virtually anything, or at least you might think so. The truth is a little bit less dramatic, but 3D printers are indeed quite powerful.

That excitement can lead to problems, and I’ve put together several tips based on experiences I’ve seen other novice 3D printer operators have unfortunately undergone.

Rushing!

Perhaps the worst thing to do is rush through the experience. There are many, many things to know, and it will literally take you weeks, if not months, to become a competent 3D printer operator.

While things are exciting, it is risky to rush through the build, setup and initial prints because at this stage you more than likely don’t know what you’re doing and could actually damage the machine.

Take it slow; there are weeks ahead for learning and rushing isn’t going to get you there any faster.

Printing Too Big

One of the first questions I always receive when talking about 3D printers is “how big can it print?” While the question is frequently asked, it actually makes no sense because objects can be split up, printed and assembled later into any size object you desire.

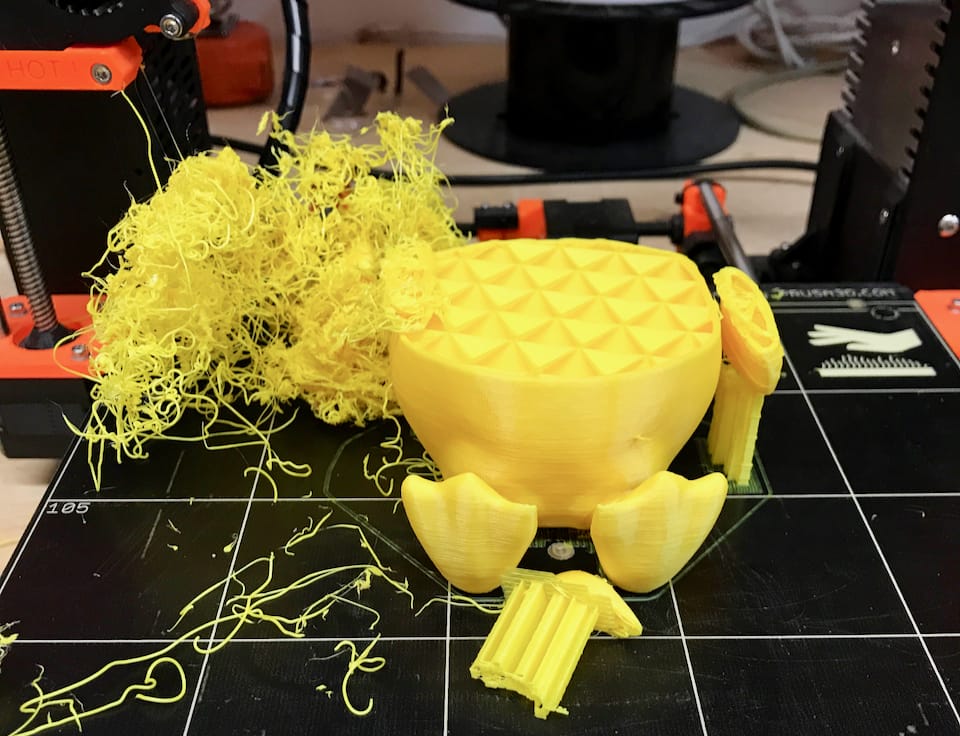

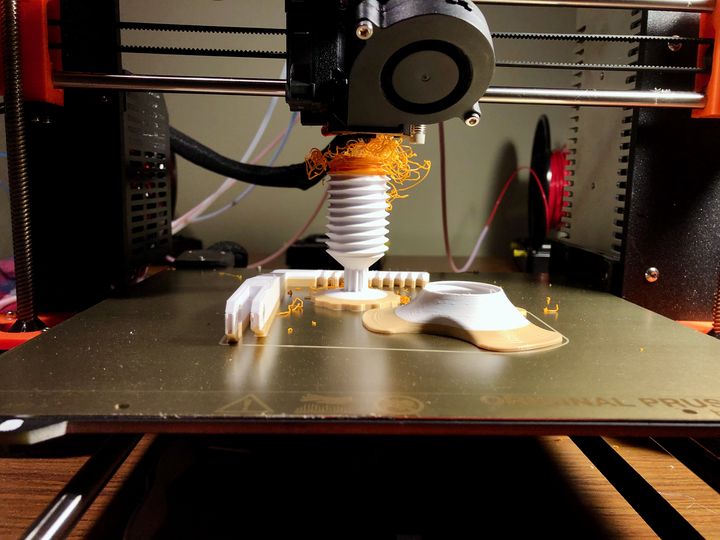

But there’s another reason: big prints tend to fail more than smaller prints, and they consequences of that failure are far more catastrophic.

The truth is that things can always go wrong with a 3D printer, particularly if you don’t yet know the proper procedures for your machine and materials. Starting a long-running 3D print will maximize the time during which a failure could occur. Even worse, when a big job fails and you’ve lost half a spool of filament for no good reason, you will realize why this is good advice.

Start with smaller prints until you feel very comfortable with machine operation.

Try Your Own 3D Models

Most 3D printers come with a USB stick with some test files. These will be pre-sliced with optimal print parameters, and are more-or-less guaranteed to work properly, if you’ve built the machine correctly.

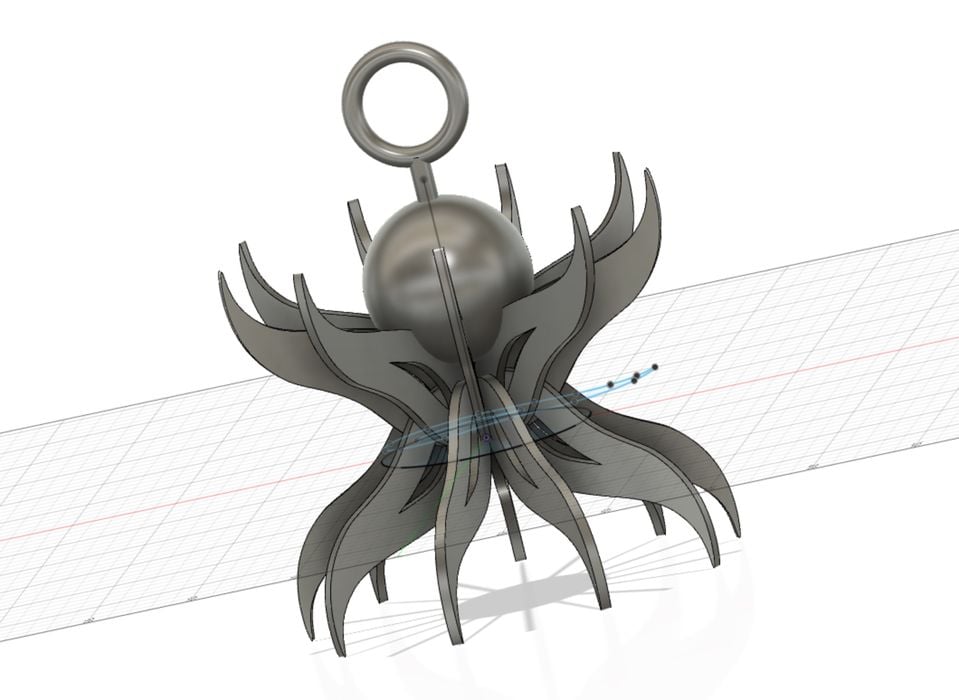

The next step would be to slice your own 3D models, perhaps even models you’ve designed yourself. That’s the excitement factor: something from your mind became a 3D model, and shortly after you’re holding it your hand — it’s an amazing experience.

But it’s one fraught with problems. It is extremely easy to design a shape that is difficult or impossible to 3D print easily. That’s something a novice 3D printer operator should not undertake until sufficient experience with the myriad of failure modes are well understood.

Try printing other designers’ 3D models first and gain an understand of what works, and what does not before designing your own 3D models.

Use Other Filaments

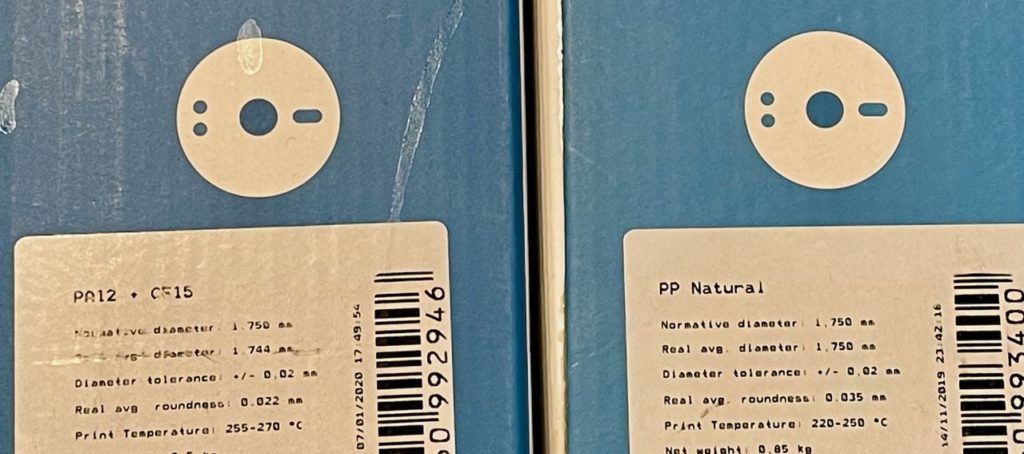

Most desktop 3D printers are set up to use PLA filament as the build material, and there’s a good reason for that: it’s very easy to succeed with a print job when using PLA.

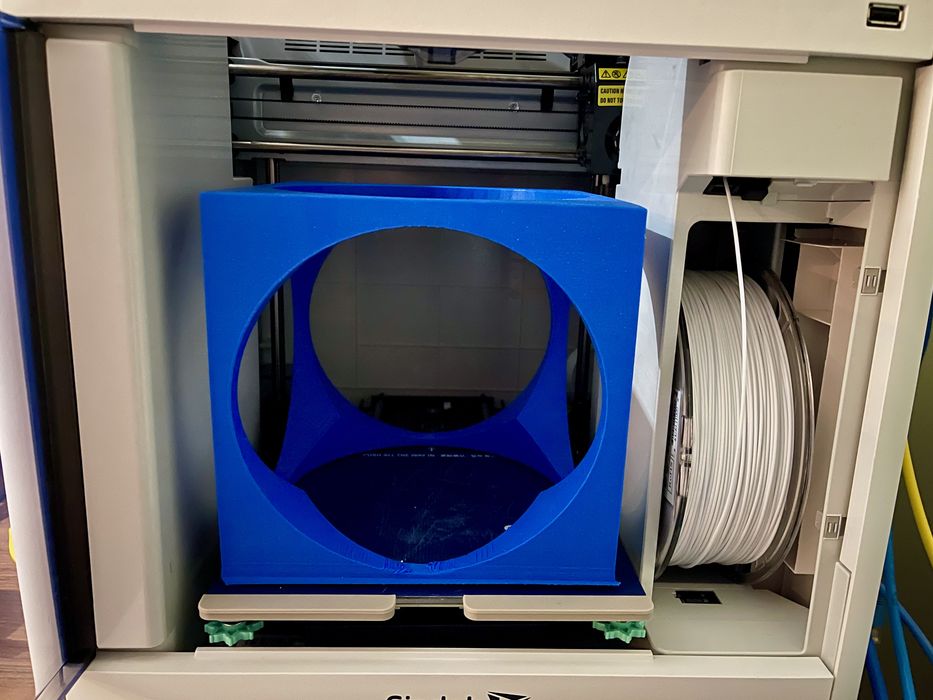

Many other materials, particularly ABS, ASA, nylons and some others require different approaches to succeed in printing. You may not even have a machine that can successfully use them.

Always use the materials intended for the machine, or you’ll get into trouble that you won’t know how to solve.

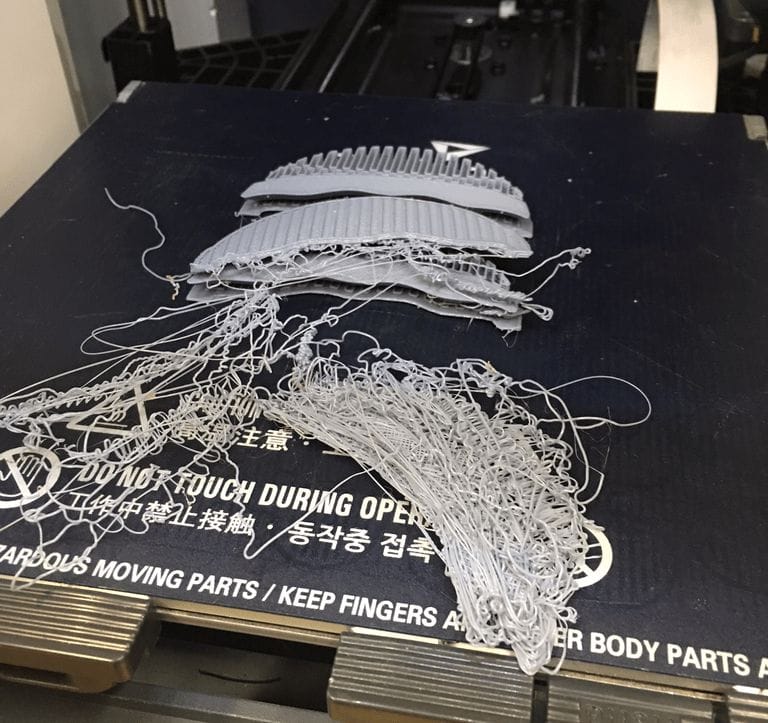

Leave It Unattended

Newly set up 3D printers do have a bit of a risk. If you haven’t set them up properly — for example if you missed removing a tie-wrap — then the print could mysteriously fail. It’s critical to carefully observe the first few print jobs to make sure everything is working properly.

It’s also important to watch every print job to ensure the first few layers are properly attached to the print plate. There’s nothing worse than finding out a job failed immediately but you extruded 1kg of material for nothing because you didn’t watch the job start.

Start A Job When Uncalibrated

Almost every desktop 3D printer requires calibration before use. This typically means two things: level the print surface and set the Z-gap between the nozzle and the print surface.

Usually there is an automated process to do these things, but you still have to invoke that process. If you proceed with a print job before calibrating, it simply won’t work and you’ll wonder why the printer has failed.

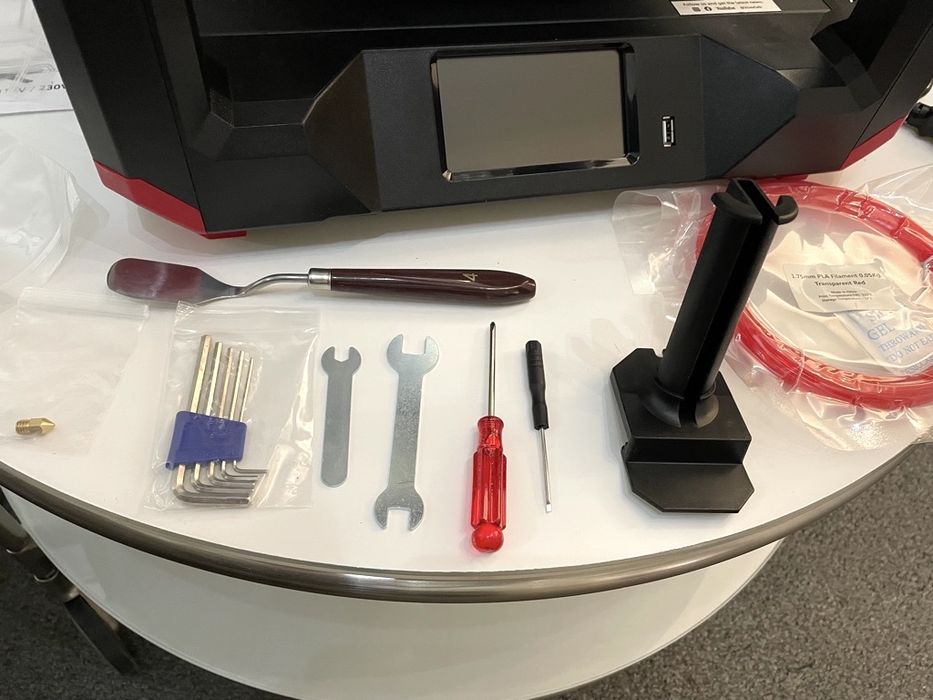

Throw Away Spare Parts

3D printers usually come with a bag of tools and spare parts. Sometimes these are very tiny, for example many manufacturers include a needle-like device for clearing nozzle clogs. It’s so small it’s very easy to misplace.

There could also be spare nozzles, wraps, bolts and other items that appear unnecessary for initial printer operation.

Don’t let that fool you: you probably will need these items sooner or later. It’s not a good feeling when your nozzle is permanently clogged with some awful glitter filament months later and you realize you don’t have the spare handy.

Make a place for those tools and spare parts that is accessible.