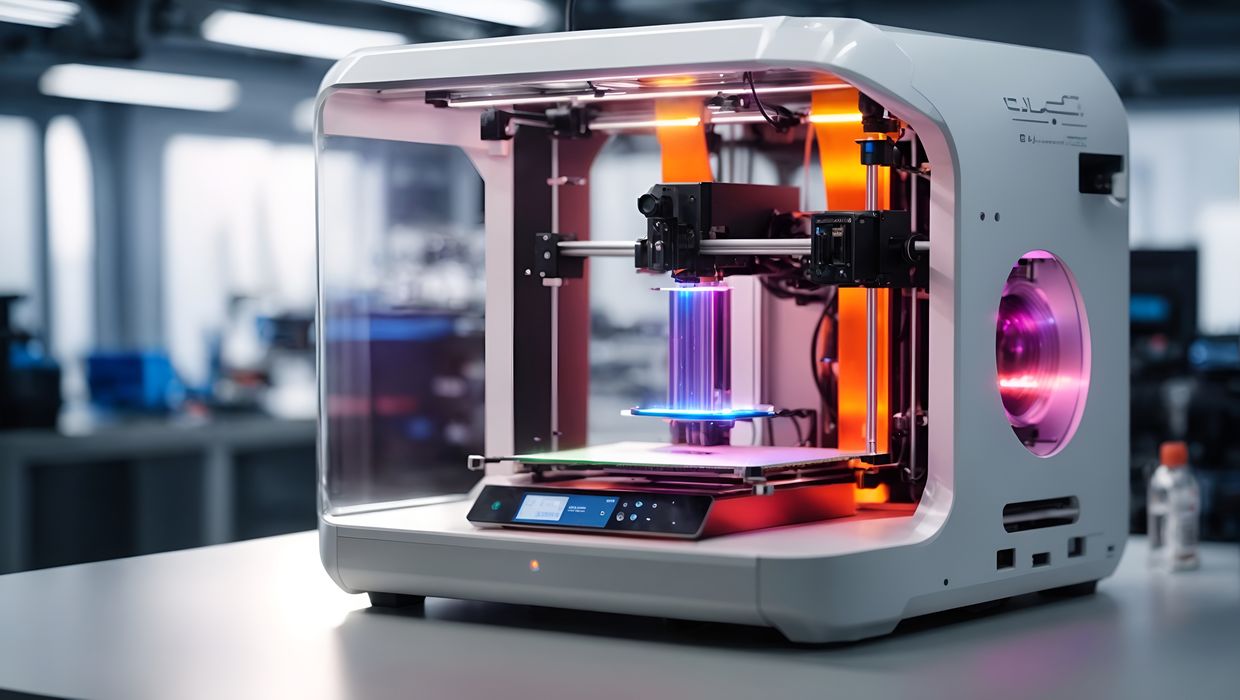

I’ve thinking a lot lately about sensors on 3D printers.

Sensors are tiny switches and detectors that can provide the controller board with information about the current state of the machine. The controller’s software can then make more intelligent decisions about what to do.

There are simple sensors, like end-stops. These are used to detect when the machine’s motion system has hit the end of its path, for example.

Some sensors provide more numerical data. An example would be the thermistor commonly found on 3D printer hot ends. These components are sensitive to heat: as the thermal environment around them changes, they carry more or less electricity. This energy level can then be accurately translated into the temperature of the hot end. It’s a thermometer for the 3D printer’s controller.

Finally, we have on board cameras, which provide an optical view of the print activity. While originally intended for use by human operators to monitor print progress, in recent years they’ve frequently been adapted for use in AI-based systems to detect print failures. This is just another kind of sensor.

Is that all the sensors required? I think things could change in the near future.

It’s all being driven by the AI revolution. Everyone has seen the magical effects of generative AI to produce amazing 2D images from simple text prompts. There’s also work being done now to produce competent 3D models from text prompts, or even from 2D images.

Because of the incredible power of new AI platforms it’s now possible to develop all kinds of unusual applications that previously would have been unimaginable. It’s likely that AI will be applied to all manner of situations, processes and equipment in the future.

One type of equipment likely to receive additional AI treatment is 3D printers.

So far the AI systems seen on 3D printers are primarily for optical monitoring as described above. However, I think there could be more applications developed in the future.

There are a few “hard” problems that have yet to be properly solved by the current crop of 3D printers:

- How to run jobs at maximum speed yet retain print quality, regardless of model geometry

- How to detect what material is being used and automatically configure the machine to handle it properly

- How to maintain the thermal environment inside the 3D printer to ensure optimal print quality

- How to detect machine components that require adjustment or maintenance

All of these things are done manually today, and that means most people don’t do them, or don’t do them properly. What if AI tools could do these and other functions automatically? I suspect the reliability, print quality, speed and other properties of the 3D printer could be vastly enhanced if so.

However, AI tools require input data. In the case of a 3D printer, that means sensors.

The implication is that we might see two things happen on future 3D printers: many more sensors of different types, some never seen on the equipment; and secondly powerful AI-based firmware and software that takes advantage of the new sensor data to accomplish some of the above functions.

To me this seems an inevitable outcome of where things are headed. It’s only a matter of time before 3D printer manufacturers start doing this, if they aren’t already looking into it inside their secret underground labs.

The end point would be “superprinters” that can handle most of the procedural nonsense we have to put up with today when operating 3D printers.

That’s something I believe everyone will want to have in their workshop.

The load cell.

Able to detect the release of film and spare you the wasted retraction time.

Able to detect part detachment so it can abort print before it crushes your screen.