Sculpteo has released their annual report on the state of 3D printing for 2021.

The now-BASF-owned French company has been releasing these detailed reports for several years, and it is based on survey results from hundreds of parties in the 3D printing industry.

Sculpteo founder and CEO Clément Moreau described this year’s report:

“Welcome to the seventh edition of The State of 3D Printing, the largest study of 3D printing users! This year’s report captures the views of more than 1900 respondents using 3D printing in a wide variety of applications and industries. This seventh edition is also the most international State of 3D Printing, we’ve ever published, with users from 86 different countries represented.”

I perused the report and picked out some highlights that struck me, which I’ll list below.

The report covers a wide breadth of usage, with 52% for “work”, 20% for “research” and 25% for personal interest, which rings true as the current spread of 3D printing technology around the world.

About half of the respondents use 3D printing only occasionally, “a few times a month” or less, while a quarter used it daily. That again sounds about right, as today there is a mix between manufacturing (constant use) and prototyping (intermittent) use.

While the most prevalent use was prototyping, among “power users” the biggest use type was “End-Use Mechanical Parts”. This clearly shows the deep penetration into manufacturing that’s occurred over the past few years.

Another statistic confirming this is that 86% of respondents are doing some level of “production”, ranging from small series to “mass production”.

As for the most desirable characteristics in materials, respondents indicated the usual pair of “Strength” and “Low Cost”, but curiously “Sustainability” has snuck into a fourth-place spot with 23% interest. That aligns with my observations of dramatically increased interest in recycled or eco-friendly materials.

Unsurprisingly, 54% of respondents spend most of their time doing CAD work, while only 22% spend their efforts on “operating machines”. That’s good news, as we’re spending more time on design and letting the robots do more of the manual work.

The two top challenges are quite interesting. The biggest item at 53% is Quality Control. It’s one thing to 3D print “something”, but quite another to produce quality parts at volume with consistency and reliability. This is again part of the shift to manufacturing, where QC is king.

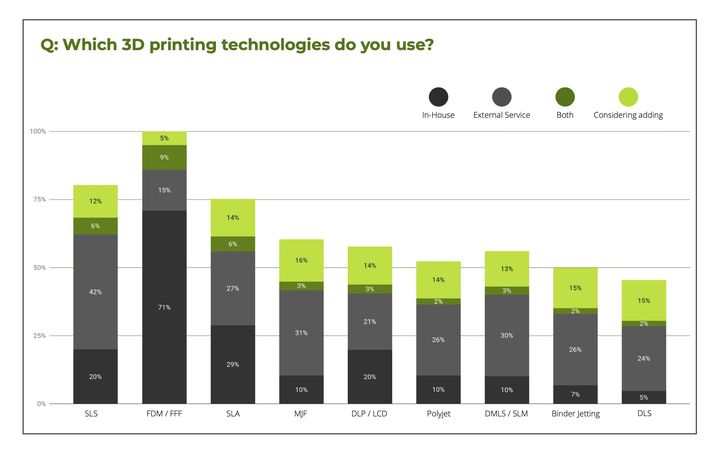

Here we see the chart of popular 3D printing technologies. What’s most interesting is that while virtually everyone uses the FFF process, SLS and SLA are not far behind. That’s quite surprising, and again indicates a rise in interest in higher-quality parts. Also note that HP’s MJF is next in line, ahead of Stratasys’ PolyJet.

While “Complex Geometries” lead as the “top benefit”, as it has for a long time, “Mass Customization” is a strong third place at 41%. This is intriguing, as it suggests there are parties producing customized parts at scale. That’s one of the long-term aspirational goals of 3D printing, and it seems to be unfolding.

As for suggestions for improvement, the results are all over the map, indicating respondents want everything improved. I have to say I agree. However, “More Reliable Technolgies” holds a slight lead. I also agree with that, having spent considerable time fixing machines myself lately.

There’s plenty more to be found in the always-interesting Sculpteo report, which is available now for download at no charge.

Via Sculpteo