3DQue announced a significant milestone is in sight for their Quinly system: one million 3D prints.

3DQue is a Vancouver-based startup that’s been working on a means to enable inexpensive 3D printers to produce larger volumes of parts.

Their approach is by using a technology they call VAAPR, which is a sophisticated print plate. The technology allows full control over adhesion: when hot, prints stick extremely well. When cool, the prints completely loosen and can even fall off if the print bed is not horizontal.

The company has deployed this tech in several different forms. It’s original deployment involved arrays of Creality Ender 3’s mounted sideways on a rack. As prints completed, they would literally fall off (because the bed was vertical, not horizontal as normal), and land in a catch bin.

These inexpensive array systems were able to produce small volumes of parts on a continuous basis through the use of 3DQue’s control software that would dispatch jobs to available machines.

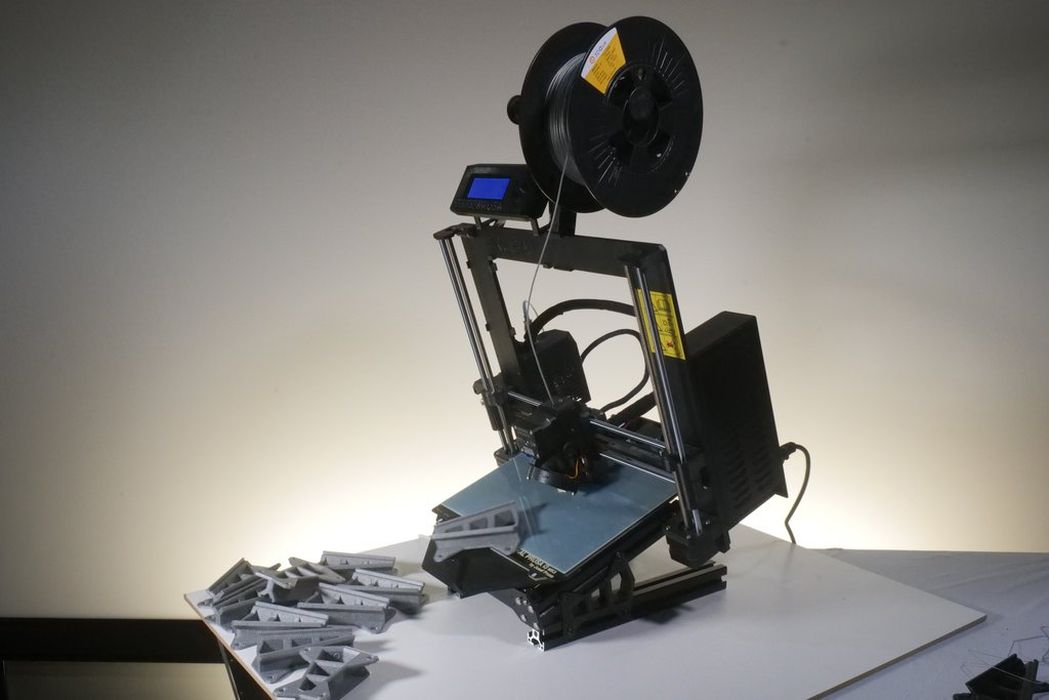

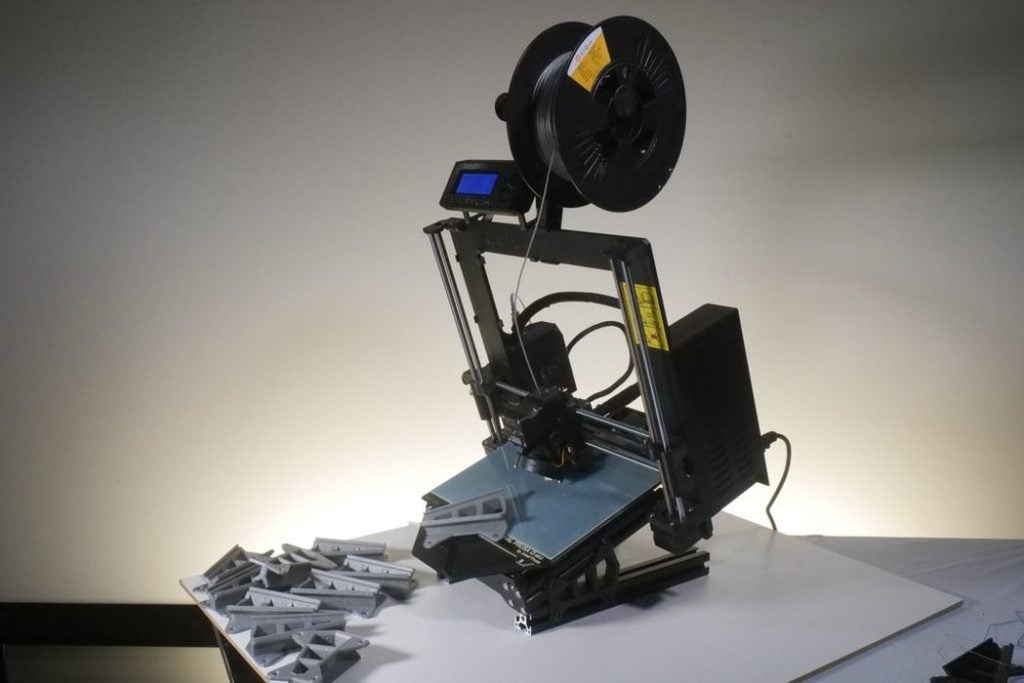

Their next deployment of the technology was bundled in a package they call “Quinly”. It’s distributed as an upgrade kit for popular desktop 3D printers, and involves replacing the print bed with a VAAPR-enabled version, as well as tilting the 3D printer so that prints would slide off when completed.

3DQue explains how Quinly works:

“Quinly automation technology has been designed from the ground up to be scalable, efficient and reliable. Quinly is a virtual operator that runs 3D printers the way a human would. It takes care of time consuming tasks such as first layer adhesion, job scheduling, and part removal. With a small upgrade to their printers, operators are able to load files into the queue and let Quinly do the rest. Quinly software runs printers 24 hours a day until the queue is empty. Real-time reporting allows operators to check in any time. Quinly even accesses a printer’s built-in calibration tools to ensure reliable repeatable part delivery every time.”

While the original Quinly targeted the Creality Ender 3 model, they’ve since added a number of other popular 3D printers, including the CR-10 series, Prusa i3 and Ultimaker S3. Their intention is to offer upgrade kits for many more machines. They explain:

“3DQue expects to have Quinly automation available for 50% of desktop and industrial 3D

printers on the market by the end of 2022.”

By that I take it they mean the models their kits target represent more than 50% of deployed equipment. That’s quite something.

The news today is that they’ve been tracking the production of parts by the existing Quinly installations since Spring when it was launched. They report that over 250,000 parts have been produced since then.

This is based on the activity of their 750 operator group that comprises the current Quinly installation base.

Based on this rate of production, the expected sales of Quinly kits, and the expansion of kits to additional equipment types, the company now projects their Quinly system will produce over one million parts by Spring 2022.

Let’s say that again: One Million Parts.

If you’re familiar with the Quinly, you’ll know this is entirely possible: the system dramatically reduces the amount of labor required to produce parts, since the machine basically runs on its own and only occasionally requires a fresh spool of material. The operator mostly empties the bin of completed parts.

I believe this is important because it provides a milestone for those still skeptical of the ability for 3D printers to be used in production.

While there may be parts that require different materials, surface finishes or other aspects, there remains a large number of parts that can successfully be produced on these inexpensive machines.

And with Quinly, they can be produced in vast quantities.

Via 3DQue