Researchers have found a method to enable 3D printing of biodegradable polymer objects.

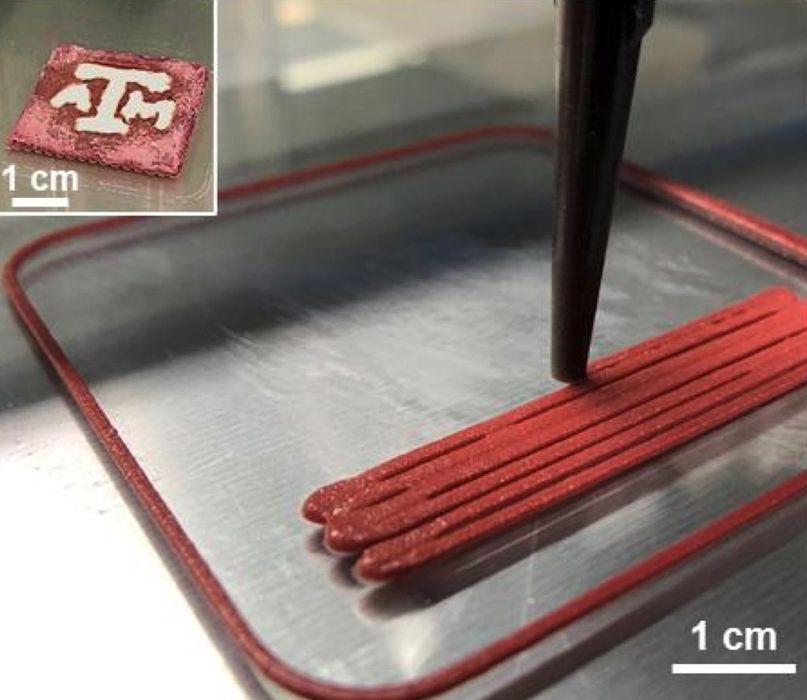

A team at the Texas A&M Department of Chemistry and the University of Kashmir have developed an unusual material and process for printing biodegradable objects.

Currently our environment is awash with plastic objects of all kinds, to the point where it is becoming dangerous. Small plastic disposable objects litter everywhere, and in some cases emit toxins that could cause harm in the future.

There are plenty of initiatives to reduce plastic pollution, including laws to make single-use plastic items illegal, or campaigns to use cardboard straws instead of plastic straws.

The problem is that once these items are discarded, it takes a very long time for them to degrade into the environment. Apparently a single plastic straw can take up to 200 years to complete disappear. Now imagine how many straws and similar items might be used over 200 years and you get the idea of how much plastic junk can accumulate.

One way to mitigate the situation is to simply reduce the use of such products, and that seems to be the way most jurisdictions are going.

However, there’s another way: change the material so that it degrades far more quickly.

That’s the subject of the researchers, and it appears they have succeeded in finding a way to do so.

Their approach was quite unique: they mixed in salt (NaCl) into a polymer ink that could be extruded via a syringe. This is a known method of 3D printing, although not particularly widespread.

After objects were printed, they were flushed with plain water, which dissolved the salt crystals embedded in the structure. This left a series of voids and made the object quite porous.

However, the processed prints still retained a smooth surface in spite of their newfound porosity.

The big idea here is that the porous nature of the print would expose more surface area to the environment, which in turn would lead to a faster rate of degradation. Normally, solid plastic objects would have to degrade layer by layer through the surface, much like a log would burn from the outside inwards.

With the porous material, the environment would have much more direct access to the material and thus natural degradation would occur at a faster rate.

In a way, this is analogous to taking plastic objects and chopping them up into smaller bits before tossing them out. The bits would also expose more surface area per volume to the environment, and lead to faster degradation.

For single use objects, this material could be useful. However, at this stage it is only basic research and commercialization would have to be investigated to determine financial feasibility, industrial efficiency, etc.

Via Wiley