Charles R. Goulding and Preeti Sulibhavi look at several startup companies developing ways to 3D print salmon meat.

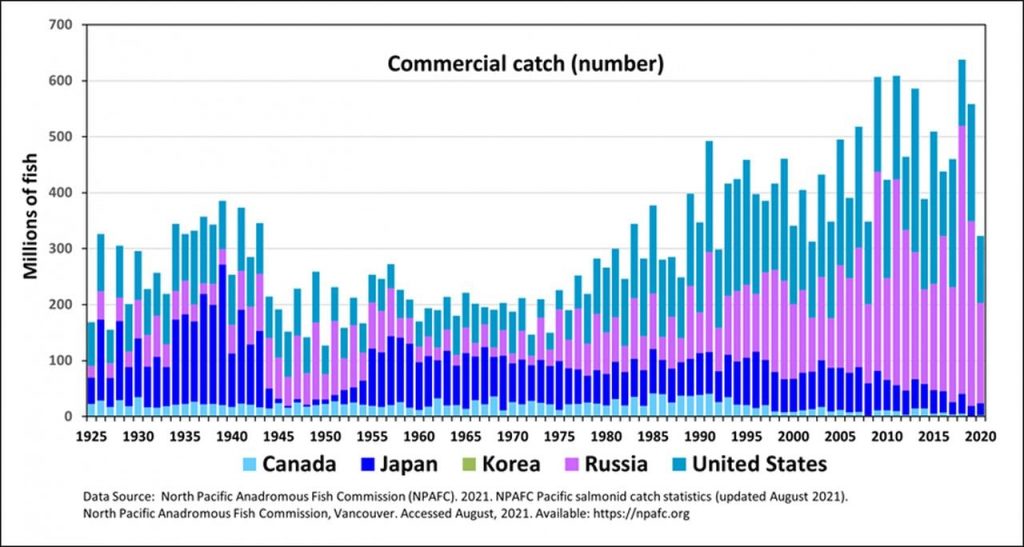

Since it began in the 1960s the farmed salmon industry has grown exponentially in the past few decades. In 2020, more than 2.6 million tons of farmed salmonids were produced in comparison to 550,000 tons of wild salmonids caught. Overfishing is contributing to the decline of salmon populations in various populations around the globe. Environmental events, pollution and disease have also added to the decline of salmon populations.

In comes 3D printed salmon.

In 2020, startup company Legendary Vish, located in Austria, began working on an EU-led 3D printing project to 3D print a vegan alternative to salmon. Legendary Vish is now re-branded as Revo Foods. With US$1.78M in its first round of funding, Revo Foods will be accelerating 3D food printing as well as expanding its current team. In the UK, Revo Foods’ plant-based salmon products will be sold by GreeBay, a popular online retailer of vegan foods.

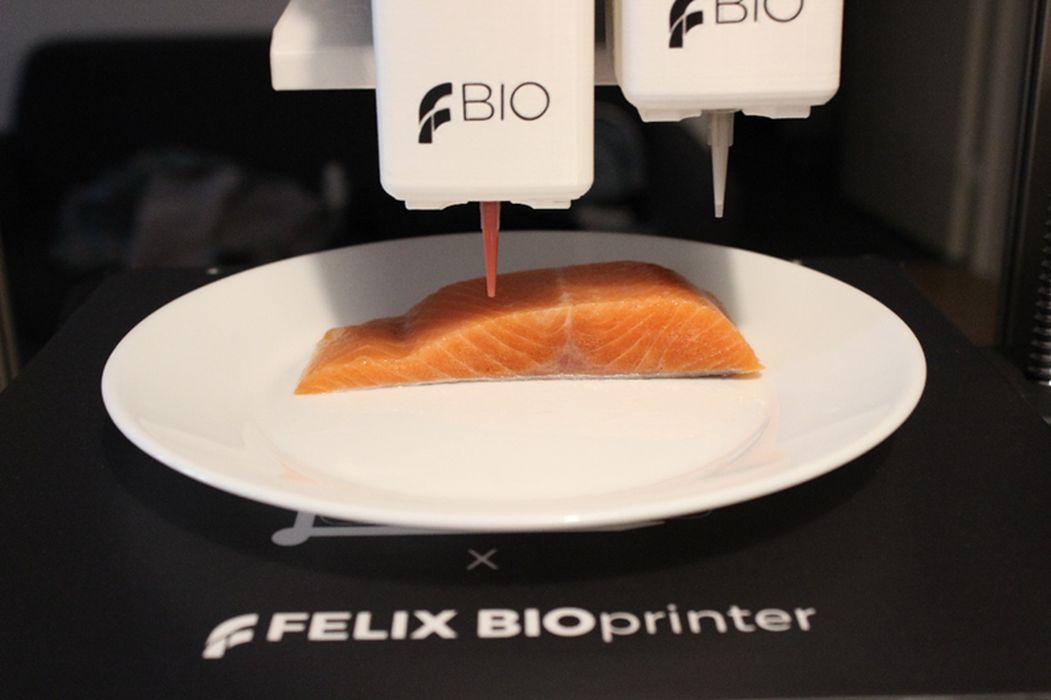

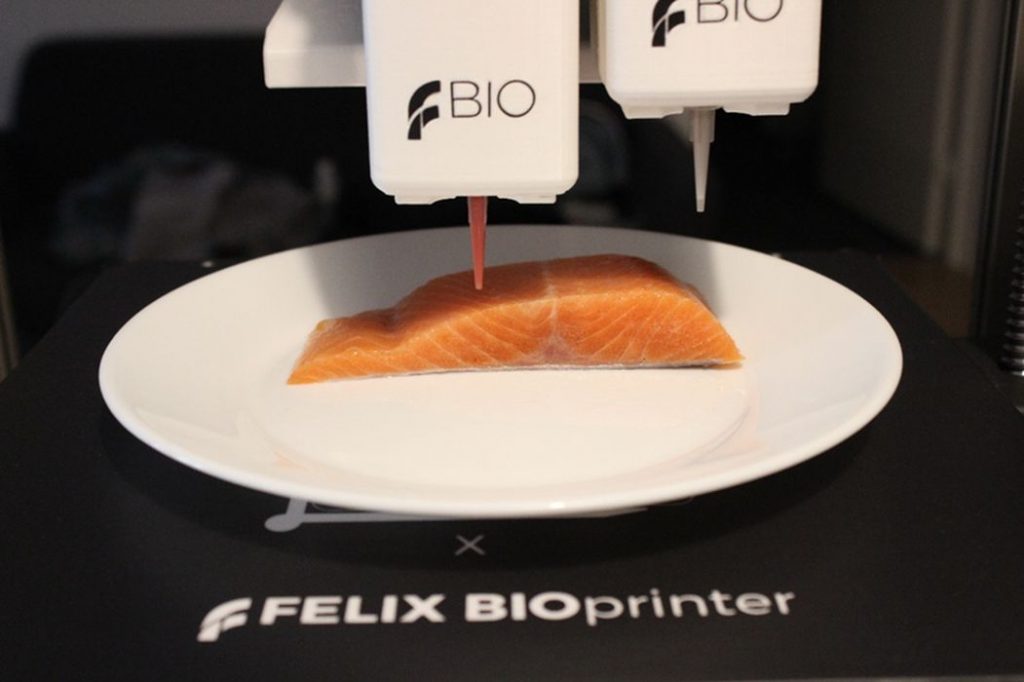

According to a Digital Engineering article, Legendary Vish developed its plant-based salmon alternative by utilizing the FELIXprinter BIOprinter, which allows for complex structures that are impossible to produce using traditional 3D printing extrusion technologies. The output viscosity of materials used in the FELIXprinter BIOprinter’s extruders are different, and help create the same culinary experience as traditional animal products. The product is featured in the headline image above.

In 2022, Plantish, an Israeli startup, announced a fully vegan, structured, boneless salmon fillet with the same nutritional value as the actual fish, but without mercury, antibiotics, hormones, microplastics, and toxins found in the ocean or aquaculture species. An official launch to this 3D printed fish is expected in 2024.

Plantish is not alone, nor will it be the last.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

It is good 3D printing is catching up with the salmon trend. There are a lot of ways to improve our health, the environment, and dinner as well. 3D printing is certainly helping put good food on the table.