Sakuú announced the launch of a new pilot facility to manufacture 3D printed batteries.

We’ve been looking at Sakuú for some time now, as they have a rather unique “multi-process 3D printing process”. I describe it that way because it is literally a way to utilize entirely different 3D printing processes within a single job, be it resin polymerization or powder fusion.

As you can imagine, that “meta process” could be used for all manner of production, including complex end-use parts. However, rather than boil the ocean, Sakuú is smartly focusing on one initial application: batteries.

It’s a good choice, because it should becoming clear to many that civilization must begin a very rapid shift to electrified infrastructure away from oil and gas. That will require truly immense quantities of batteries to store and deliver electrical power to devices, vehicles and buildings.

If one were to invent a way to economically and rapidly produce large quantities of functional batteries, you’d be in an exceptional position for massive growth.

That, no doubt, is the thinking at Sakuú.

However, in order to get there the company will have to prove that their concept works at scale. It’s one thing to make a prototype, and quite another to reliably and efficiently manufacture millions of units.

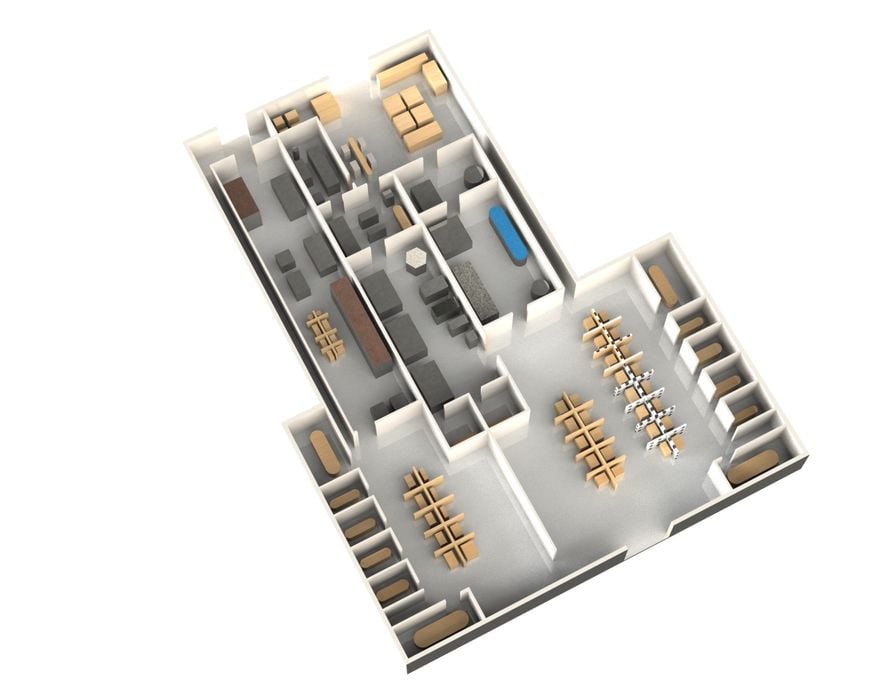

That is precisely the next step being taken by Sakuú, as they are beginning the build of a large “pilot line” to use their technology to produce quantities of batteries, which are said to be both 50% smaller and 30% lighter than equivalent capacity lithium-ion batteries.

Sakuú has partnered with Honeywell Process Solutions and Relevant Industrial to assist in developing the manufacturing system, which will have to be finely tuned in order to meet their production demonstration goal.

Sakuú explains:

“This pilot line will demonstrate the viability of the battery manufacturing process and enable Sakuú to deliver sample products to its Early Access strategic partners. Relevant and Honeywell will aid in the process design by taking Sakuu’s proprietary technology and scaling up the lab environment into a fully functioning pilot manufacturing plant.”

That goal is to produce at the rate of 2.5MWh of batteries per year. To put than in perspective, that’s equivalent to delivering approximately 140,000 Tesla 2170 cells, or about 540 per work day. Of course, the batteries being produced will be a different format, so the quantities of batteries will be somewhat different, but you get the idea.

Should the initial pilot line succeed, the company intends on expanding to 1gWh in 2022, approximately 400X the production capacity. That’s an enormous amount of batteries, and most definitely would prove Sakuú’s concept.

If they succeed, this would surely become one of, if not the, largest 3D print production facility in the world.

Via Sakuú