Bambu Lab has issued a “recall” on their A1 system.

They’re terming the move a “callback”, but it is essentially the identification of a design flaw in their latest machine, the A1 desktop 3D printer. The nature of the flaw is such that in some extreme edge cases, electrical shorts could develop. However, there is a very low risk of this happening.

The design flaw involves the pluggable cord that connects the heat bed to the printer’s base. The cord supplies power to the heat bed, along with signal information. Apparently it’s possible to bend the cord at the point of entry to the base and damage the wiring inside.

Normally this type of damage is handled by appropriate design for strain relief, but Bambu Lab discovered that in some cases their design might be insufficient. They explain:

“The investigation has revealed that the cause of these issues is linked to the damage at the root of the cable which is the connecting point of the heat bed cable and the base of the printer. To a very small portion of A1 printers, excessive bending caused by external force leads to damage to the cable at the root. This damage might not immediately cause the cable to fail, but it will make the cable more susceptible to fatigue and damage in later use. Although the fuse on the heat bed will prevent the bed from overheating, and the fuse on the power supply will prevent any short circuits from developing into any meltdown, this damage will affect the reading of the temperature and may cause power loss or even short circuits. We think it is a serious threat to the safety that we should address.”

This cable normally absorbs a lot of movement from the rapidly shifting Y-axis on the A1. Evidently Bambu Lab tested that aspect extensively, but not the other possibility of external force bending the cable.

What could cause this, aside from deliberate sabotage? Bambu Lab suggests that if one were to tip the A1 on its back, for example, this cable would bend and possible damage its internal wiring. Another possibility is extreme force encountered during shipment.

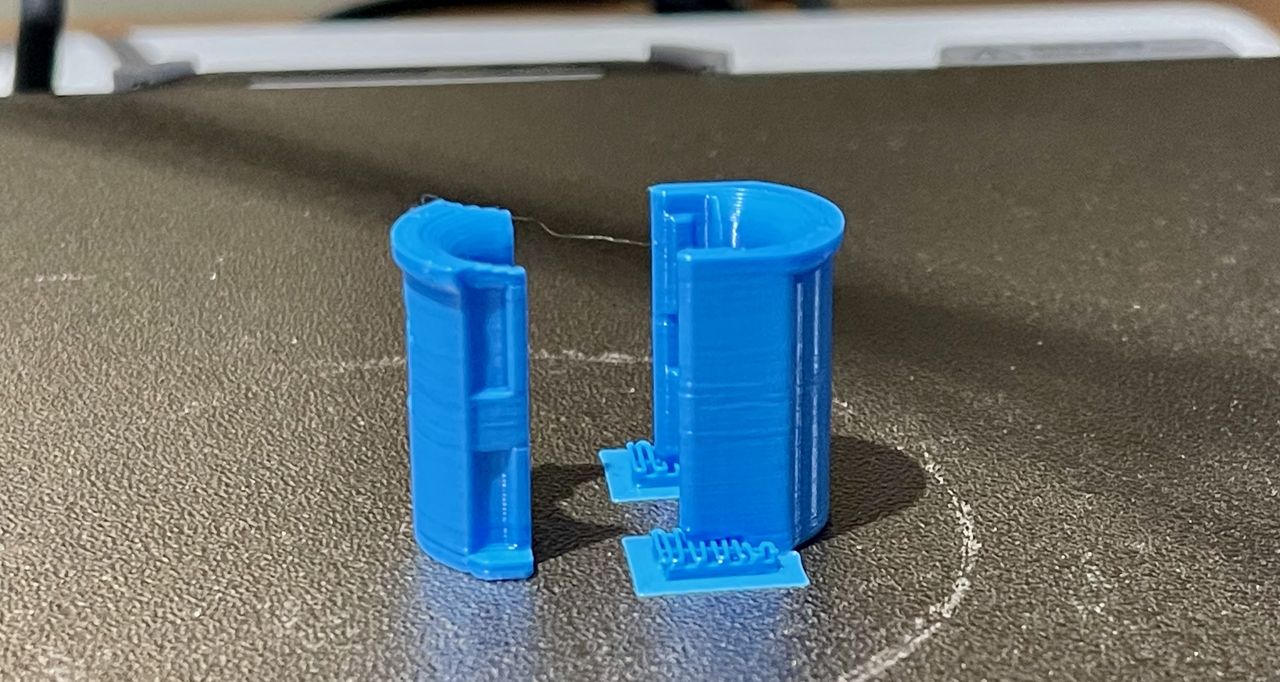

Their post shows visuals of how a damaged cable would appear, and they offer a replacement program. For non-damaged cables, they provided a downloadable cable protector specifically designed for this cable. You can see an image of it at top, and it’s easily 3D printed.

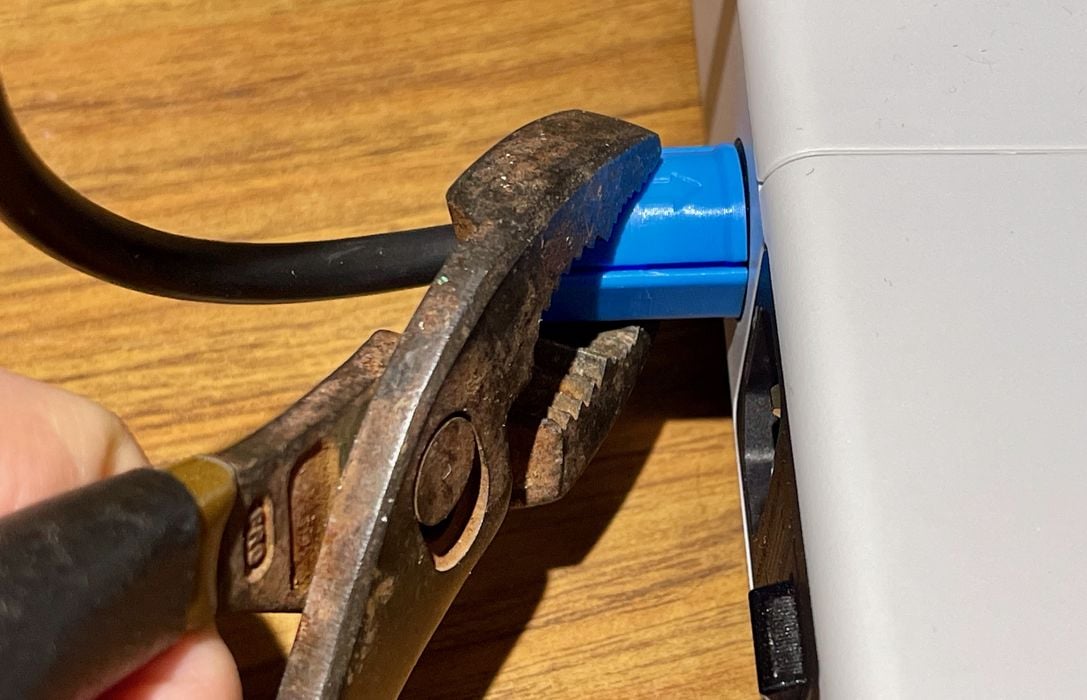

It’s easy to print, but to install I used pliers to crimp the two sides together around the cable. Note that Bambu Lab strongly recommends powering off the system before doing this installation.

Bambu Lab explained they are fixing the cable design to prevent these issues in the future, and they intend on doing this for every unit that hasn’t yet shipped. They’re providing significant details of the entire process in their ever-growing Wiki.

What’s impressive about this announcement is that it demonstrates considerable transparency from Bambu Lab. There are quite a few other companies I’ve worked with that I suspect would simply ignore an issue like this until catastrophe strikes. Here, Bambu Lab has stepped up right away and provided full details and ways to resolve the situation before bad things happen.

Every 3D printer manufacturer should act like this.

Via Bambu Lab