rpm announced a new research project in which they are to develop advanced lattice structures for additive manufacturing applications.

The German company operates as a 3D print service, focusing on Carbon’s DLS equipment. They’ve been using this equipment for three years, and have had many interactions with clients seeking solutions that were not available at the time.

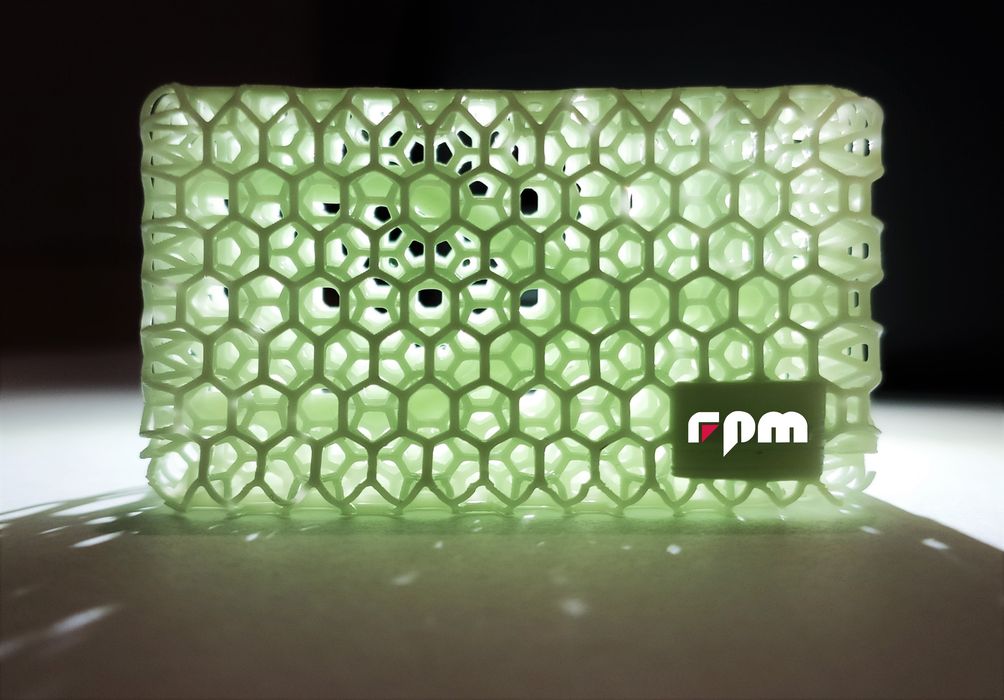

The core idea here is lattices, sparsely-built structures that offer different mechanical properties than a solid part made from the same material. The use of lattice structure is critical to the success not only for manufacturers developing advanced lightweight parts, but also for the 3D print industry as a whole, because those structures can only be built using 3D printing technology.

Carbon knows this well, and has taken significant strides in developing their own lattice tools. These would be used with clients who otherwise wouldn’t be able to design advanced parts for production on Carbon’s equipment. Carbon has had great success in this approach, as it is an easy path for manufacturing clients to rapidly get advanced products to market.

However, there are lattices, and there are lattices. The simplest form is simply a random foam-like structure. Other lattices are more regular, with a kind of 3D array of uniform cells. Carbon’s technology allows the generation of lattices with varying cell size, which means you can produce parts that have gradients of flexibility, for example.

But there’s even more that could be done, and that’s where the new project from rpm comes in.

They’ve received a grant for the ZIM project from the Arbeitsgemeinschaft industrieller Forschungsvereinigungen to help increase the technology available to German manufacturers. Specifically, the project will investigate these advanced lattice applications:

- Directed cooling channels (active and passive) within padded structures

- Use of pneumatics to control mechanical function

- Using liquid to control mechanical function

- Integrating thermal cooling and heating within elastic parts

- Influencing dampening performance with air and liquid

- Integrating flow systems within elastic parts

The goal is to produce a kind of library of advanced components that can be applied to new product development to create unique parts never seen previously. If they succeed, then rpm would have at their disposal a powerful array of features that would also attract considerable business their way. I’m certain Carbon is quite interested to see how this project proceeds, too.

rpm explains:

“To create a reliable production stream for these flexible lattices with thin integrated channels rpm needs a precise calibration of product function, lattice design, material reliability and machine performance. The ZIM research funds will support the development of these pioneer production processes. The lessons and processes will be applicable for a wide variety of products from electronic goods to automation and from high-end consumer goods to performance machines.”

rpm’s Technical Managing Director Dr. Jörg Gerken said:

“rpm recognizes that lattices will continue to be a key application from the both the technological and material perspectives. After working with regular and irregular lattices in EPU materials for more than two years, we are ready to establish this next generation of production. The ZiM grant gives us the extra fuel we need to perform the necessary R&D and prepare for rapid product manufacturing.”

I believe this is a glimpse into the distant future of additive manufacturing, where every factory of the future will have libraries of advanced components on hand for the development of insanely complex products. These could become so common we may all become accustomed to using them.

Via rpm