A very unusual design for a 3D print extruder has been patented.

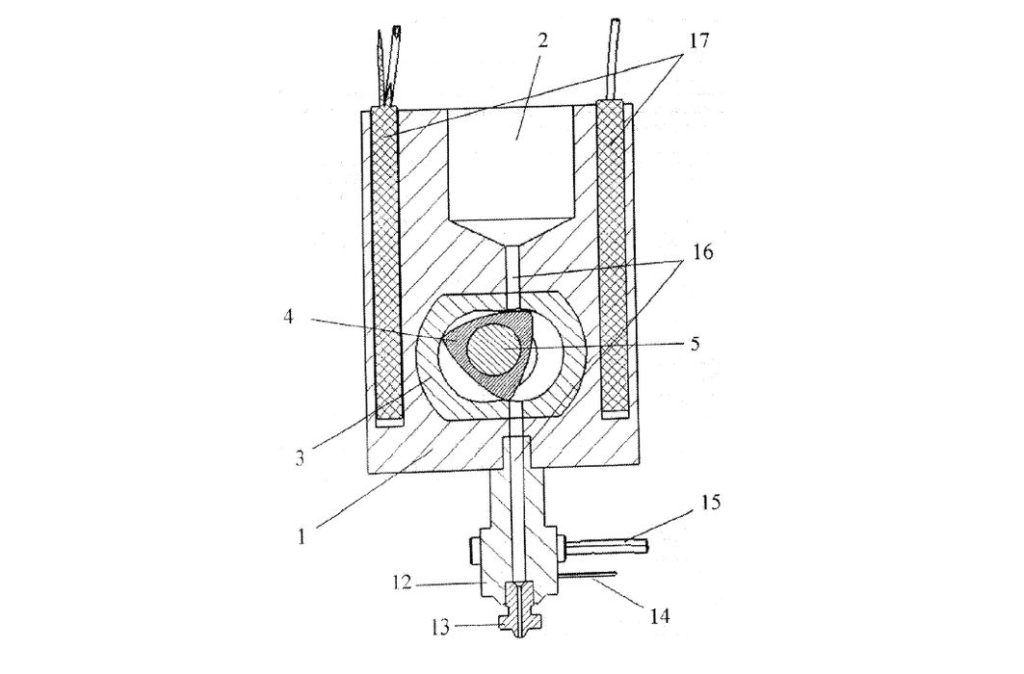

The patent, obtained by Kazakhstan-based Marat Temirbulatov, includes a fascinating rotary piston with the mechanism.

Current hot ends are quite straightforward; they simply allow a filament to pass freely and then focus down to the nozzle size. The most complex hot ends are for multi-filament systems, in which several filament paths lead into a small chamber where mixing can occur. There have also been a few specialized nozzles modified to increase heat flow.

But in this new patent, Temirbulatov has an entirely different approach to extrusion.

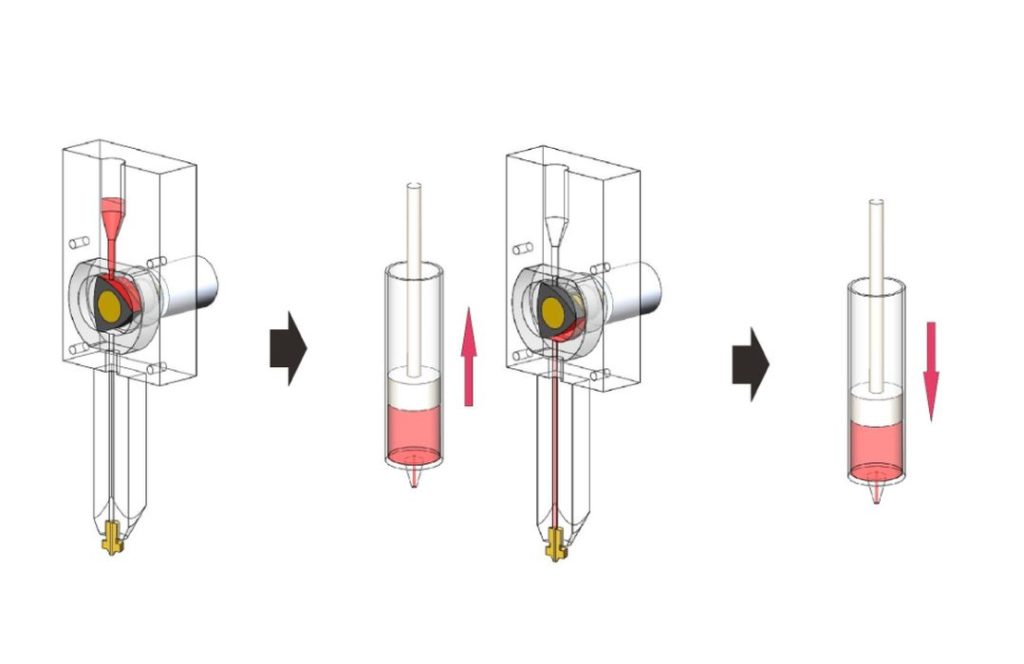

The concept is to use a rotary piston that spins during extrusion.

As the piston turns it first slurps in some material into the upper part of the chamber. Temirbulatov calls this the “suction phase”. Simultaneously, material already collected moves downward and is pushed through the nozzle tip. Another rotation brings fresh material to the nozzle and the process repeats.

There’s a couple items to note here.

First, this setup obviously requires use of non-solid materials, as a solid filament, for example, would instantly jam the piston. Filaments would have to be pre-softened ahead of this extruder.

However, the piston extruder would be entirely suitable for a variety of different materials, such as softened thermoplastic, pastes, gels, liquids, and perhaps even biomaterials. Powdered materials could be mixed with a gel or liquid to be used in the system as well.

There are metal pastes that might work well in this system, although they would require post processing to change the parts from green to brown to finished states.

The second implication is that extrusion takes place in bursts, rather than continuously. However, it may be possible with a long path to the tip to induce pressure that performs more or less continuously.

Temirbulatov explains:

“This extruder changes the printing process a bit. Printing is carried out by ‘liquid materials’, those. If we are talking about plastic, then it enters the receiving chamber already in the form of a melt, which has a positive effect on the stability of the material supply and increases the printing speed, excluding traffic jams and other troubles present in conventional printing. The requirement for the geometry of the bar is also reduced.”

Temirbulatov forecasts many different potential applications for this technology, including space applications. There are such a wide variety of materials that could work in this system it may lead to the development of 3D printers with far more material capabilities than today’s equipment.

As of now, this a patented concept, and there is plenty of work to do to make this into a product, let alone working in a 3D printer.

I’m wondering if any readers are interested in contacting Temirbulatov to explore this new technology?

Via Google Patents, Tarazbot and LinkedIn