After speaking with Roboze representatives, it seems the company is going full-out on materials.

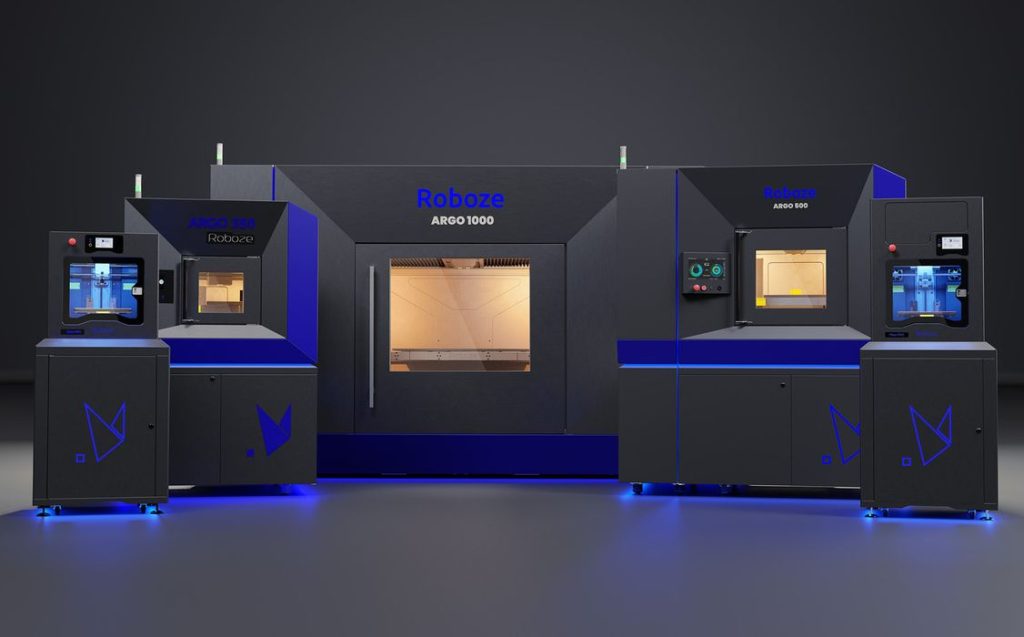

The Italian company, based in Bari, has produced a series of increasingly sophisticated high temperature 3D printers for industry. Their current flagship machine is the huge Argo 1000, which can produce parts in PEEK and other high temperature materials at up to 1m in length.

They are investing “a lot” into materials development, and even have a new, large-sized lab in Bari to do so, along with new materials scientists and nanotech specialists to do the work.

Why focus on materials so strongly? It’s long been said that 3D printing is all about materials, and that’s still true: buyers won’t purchase a machine unless it can print parts in the specific materials they require.

But beyond that there is another reason, and it’s one that other 3D print companies should take note of: there is a growing interest in sustainable materials.

Roboze believes there are a number of companies now seeking to replace their fossil-based thermoplastic materials with bio-based equivalents. In many cases, such materials don’t exist, and they’ll have to be developed.

This may seem like a sideline issue, but Roboze is very forward-thinking here: some companies have, or will soon have, deadlines by which they must replace their materials with sustainable equivalents. That’s going to put a huge demand on AM companies that will need to provide the support for such materials.

However, in many cases there won’t yet be equivalent materials, and that’s where I suspect Roboze may be heading: to create those materials.

They believe it’s possible in some cases to “reduce 60% of CO2 emissions with filament”, and statistics like that will become incredibly important in coming years.

Roboze is apparently working with the US petroleum industry for standards for materials.

It’s not just about polymers, either. They specifically mentioned “nanotech” during our discussion, which strongly suggests they will intend on producing “super materials” that involve microscopic combinations of substances. These could produce highly unusual materials with very intriguing possibilities.

All this effort is certain to attract the attention of providers interested in using their technology with new materials. One new participant in their global parts network they’ve just landed is QuickParts, one of the largest part producers on the planet. It’s likely more will follow.

The bottom line here is that we should expect to see a lot more new materials from Roboze in the future, and we’re told they are “working on something for next year.”

As Roboze’s Ilaria Guicciardini told us:

“Materials make the market!”

Via Roboze