New research demonstrates an ability have potentially infinite build volume when 3D printing.

Researchers at University College London have been investigating the problems encountered when attempting mobile 3D printing. This is a different style of 3D printing in which the 3D printer itself is mobile, rather than the static affairs we’ve all come used to.

Today’s 3D printers come in basically two forms:

A fixed build volume in which all the printing takes place

A robotic system in which the build volume is determined by the robot’s “reach”

Some of the latter systems have been extended by relocating the robot after printing a portion of the object, and then continuing. However, these approaches are rarely seen because there’s a horrendous problem to overcome.

That is registration. When all 3D printers begin working, they have a very definite understanding of where the coordinates are physically located. If you were to instruct the 3D printer (via GCODE) to move to location (123, 66, 275), it would reliably move to exactly that place in 3D space. It knows how to get there because it knows where (0, 0, 0) is located. It knows this because the machine moves its axes to the limit switches.

If you were to move the system, how does it know where the new (0, 0, 0) is located? If it doesn’t, then it risks misalignment against previously 3D printed material.

This is a highly complex problem, and I’ve been waiting to see someone solve it.

It’s so complex that I decided some early mobile construction 3D printing ventures were clearly not feasible because of this problem: if you have mobile concrete extruders running around a build site, how can they possibly know with any precision where anything is actually located?

Now it seems that considerable research has taken place on this issue with the release of a new paper entitled, “Autonomous Mobile 3D Printing of Large-Scale Trajectories”.

They explain their project:

“In a previous paper, we developed a high-level planning algorithm to automate M3DP given a print task. The generated robot-base paths avoid collisions and maintain task reachability. In this paper, we extend this work to robot control. We develop and compare three different ways to integrate the long-duration planned path with a short horizon Model Predictive Controller. Experiments are carried out via a new M3DP system — Armstone. We evaluate and demonstrate our algorithm in a 250 m long multi- layer print which is about 5 times longer than any previous physical printing-in-motion system.”

Mobile 3D printing could be a clear winner for large-scale objects, as there would be no requirement for expensive gantries and motion systems. Instead, the printer itself simply wanders around the building area, printing portions within its reach until the object is complete.

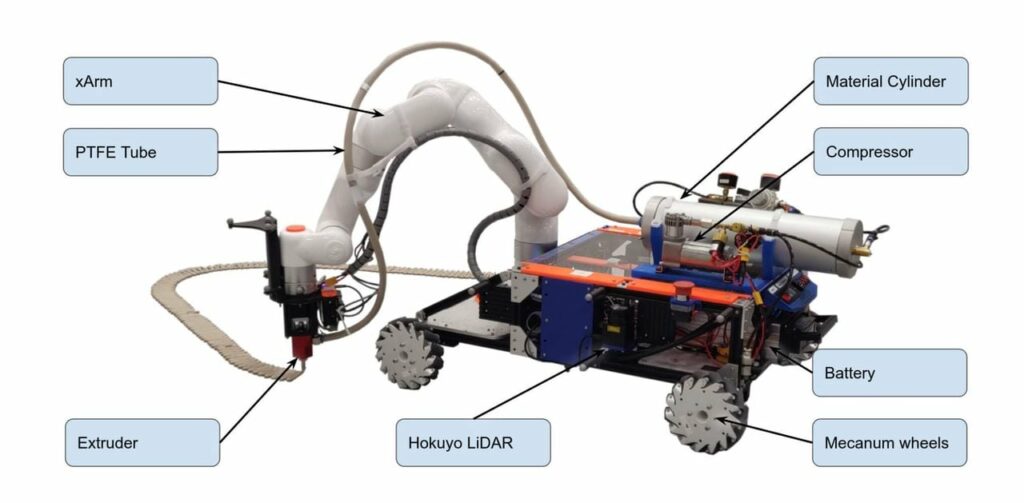

The Armstone solution involves a battery-powered mobile robotic system that includes a toolhead for extrusion. Sensing is done via on board LIDAR sensors that can detect the current surroundings. Of course, there is a lot of very complex software under the covers that direct the Armstone appropriately.

Incredibly, the system is able to hold positioning error to an average of only 0.6mm, which is certainly more than sufficient for almost all construction 3D printing projects.

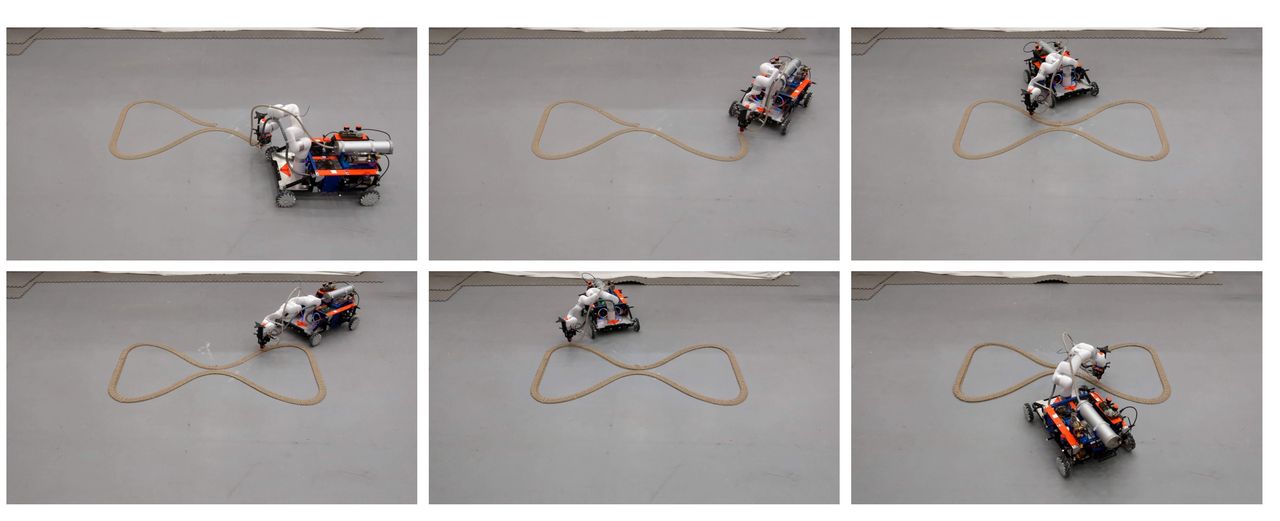

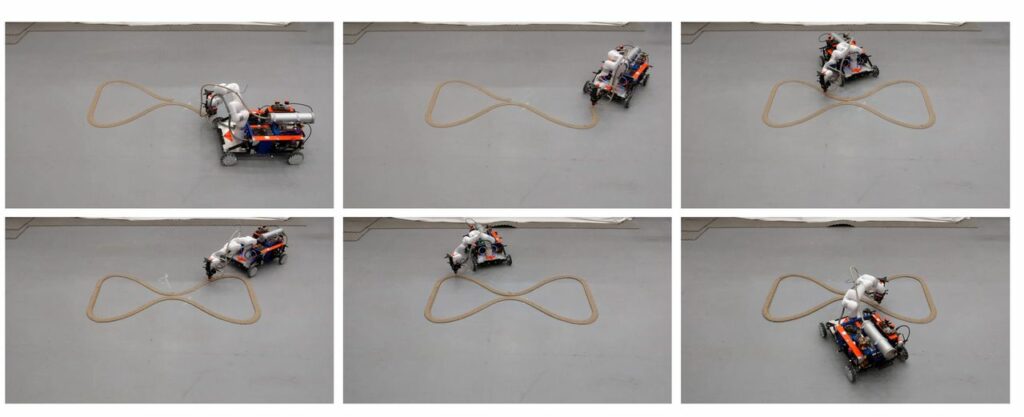

But does this really work? It seems to, as the researchers successfully executed a test of the system to produce a tool path of 260m. While the object produced was not that large, the system demonstrated that the Armstone could move about and produce a competently formed object while doing so.

There’s plenty more work to be done on this technology, but it appears quite hopeful. My thought is that this will eventually make its way into the world of construction 3D printing, which is currently being held back by build volume concerns and overall costs. An inexpensive robotic system that could build large objects by moving around will be very attractive.

True freedom from the build volume is achieved.

Via ResearchGate