A new revolutionary open source, high-speed 3D printer design has been released, and it should shake up the market.

The new design is called “THE 100”, and while the name seems unusual, there is a stunning reason behind it.

The project is the brainchild of Matthäus Szturc (a.k.a. Matt the Printing Nerd), who has been exploring the high-speed DIY 3D printer for some time. Szturc told us:

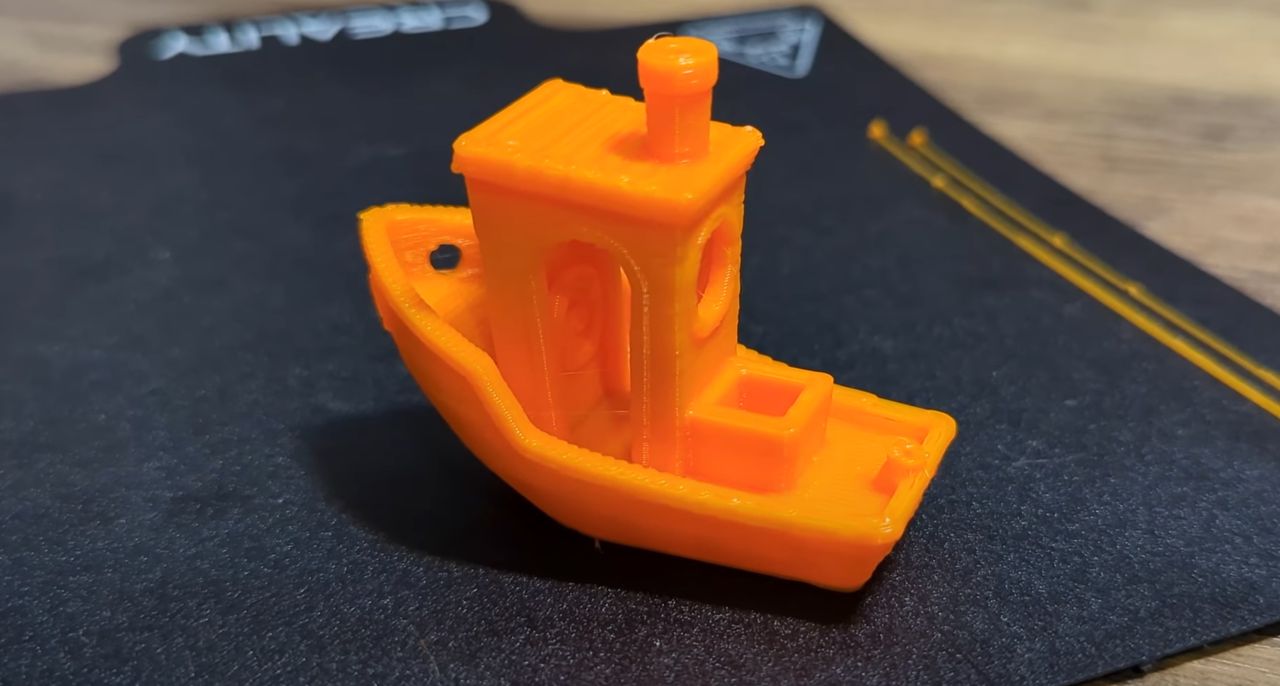

“Today I’ve released a project that I’ve worked on for 6 month.My goal was to create a 3D Printer based on a self printed frame that was capable of printing speedboats to attempt at the #speedboatrace. As far as I know this is the first printer that was able to print a #3DBenchy in < 6min. that’s not based on an aluminium frame.”

If you’re not aware, there are a significant number of people working to resolve the long-standing issue of FFF print speed. While there have been some fast 3D printers, the majority still print at the relatively slow speeds of 40-60mm/second.

There are high-speed 3D printers on the market, but they generally cost far more than common desktop devices and their price range is usually far off from feasible levels for many. However, several open source projects have taken up the problem with new and unique designs.

The most well-known project of this type is from Voron Design. This project, which launched in 2015, now has several designs available. You can build them by sourcing your own parts, or order kits for assembly. Their smallest design, the Voron 0, has kits priced at near US$400. However, while the machine can print at more than 120mm/s, it has a tiny build volume of only 120 x 120 x 120 mm, and larger volume Voron designs cost much more to build.

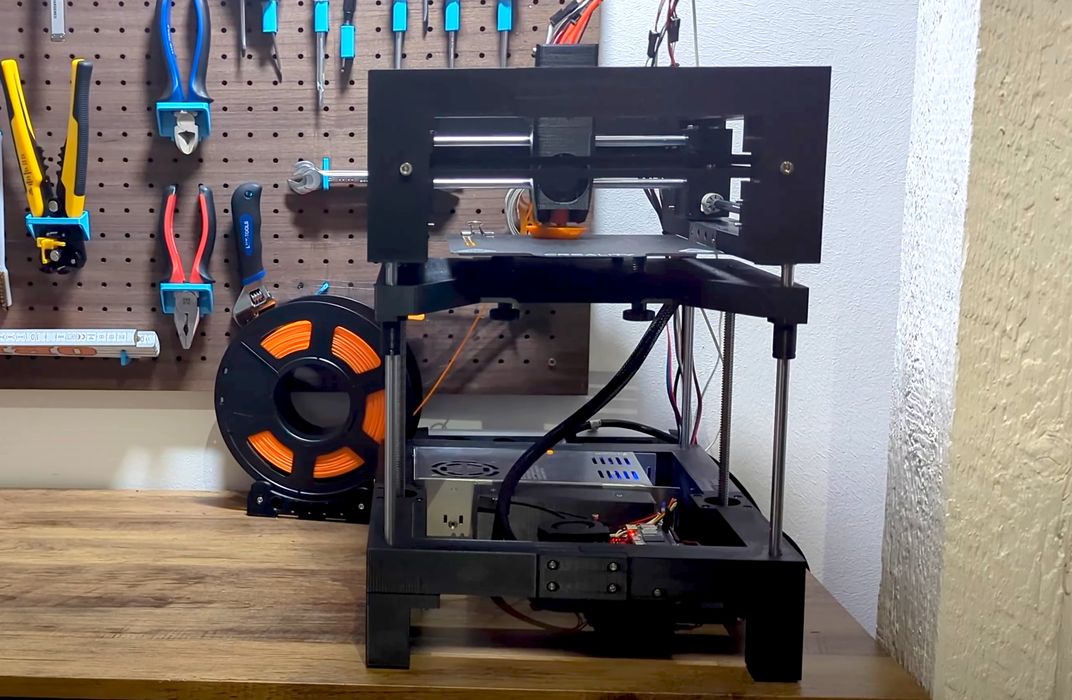

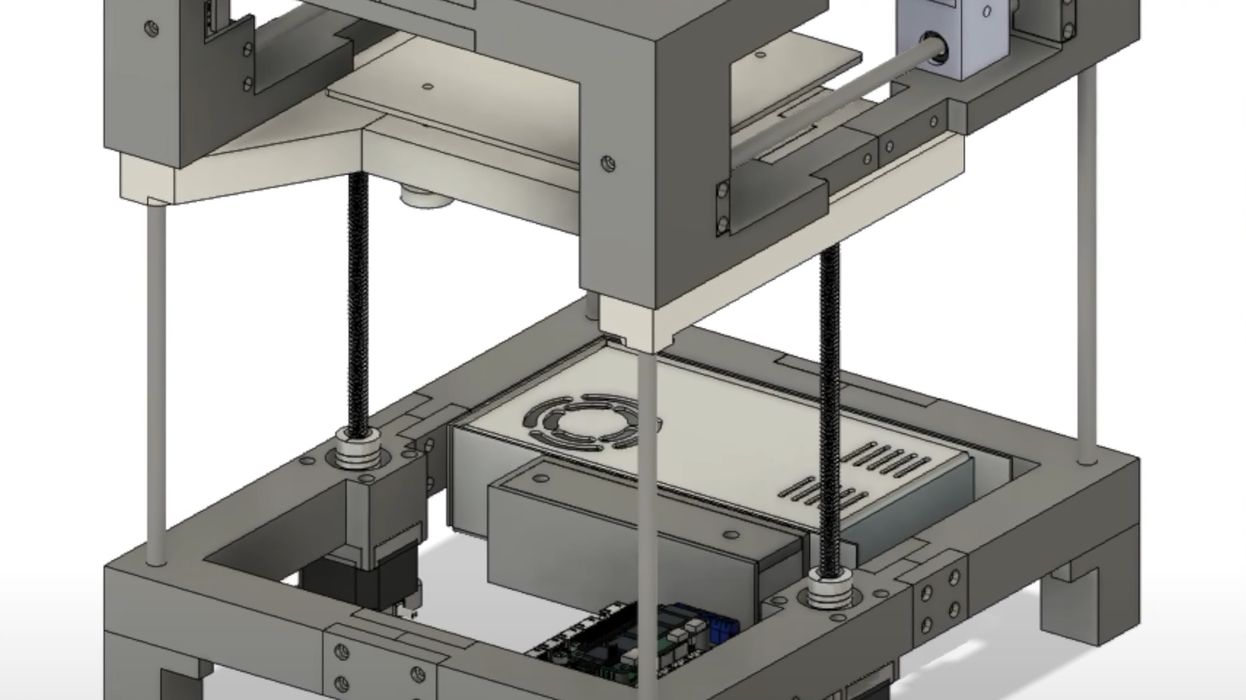

Szturc wanted to break through this build volume barrier, while maintaining high print speeds and keeping costs low. The new design for THE 100 achieves these goals: its build volume is 165 x 165 x 165 mm and it can print at up to 10X the speed of a typical desktop 3D printer, with motion systems speeds of up to 400mm/s. Most importantly, the estimated build cost for this design is a mere US$350, less than a Voron 0.

THE 100’s print speed is impressive, and it’s all about Szturc’s design goal: to achieve accelerations of an astounding 100,000 mm/s2. That’s where the name of the design originated.

THE 100 is able to 3D print a decent quality #3DBenchy in just under six minutes, which tells you how fast this machine can be. In fact, the machine is apparently in sixth place on the #speedboatrace challenge.

The machinę also includes a heavy-duty hot end and extruder, able to push out huge amounts of material to keep up with high speed operations. In addition, there is a specially designed cooling system that can very rapidly chill any extruded material.

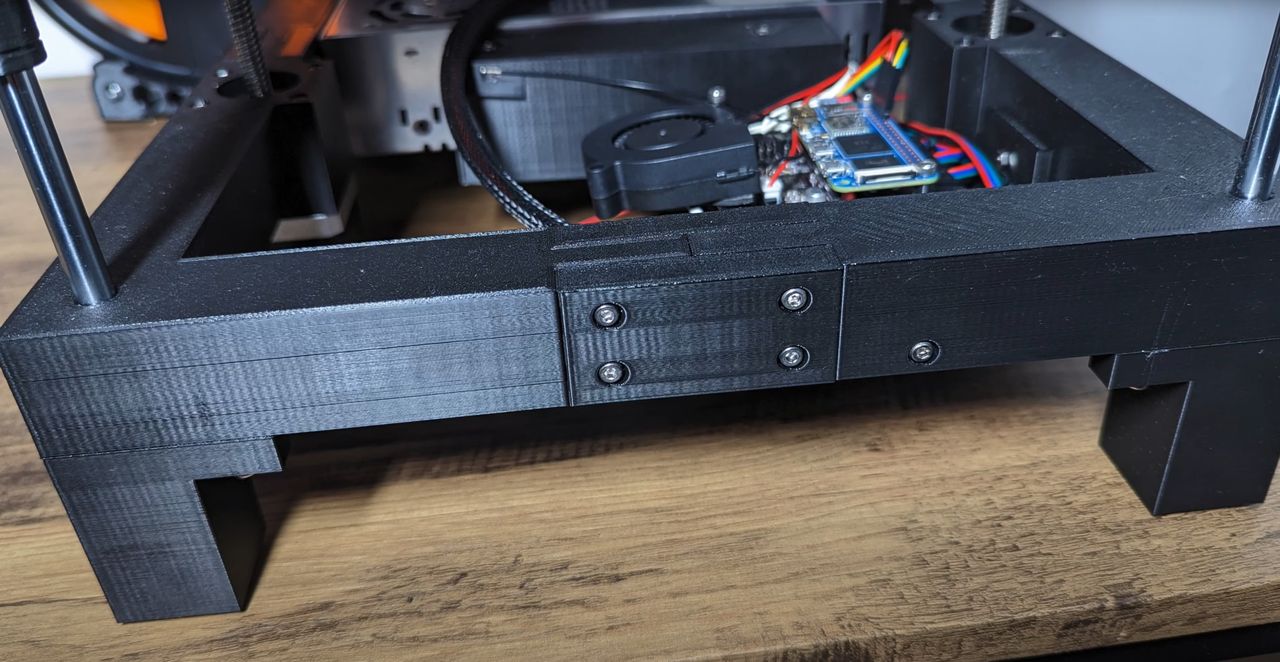

While that’s all quite impressive, what’s even more astounding is that THE 100 has a 3D printed frame!

Normally 3D printer frames are made from highly rigid material (e.g. metal) in order to reduce vibrations. The more rigid, the better.

Szturc had previously designed and built 3D printers with 3D printed frames, but found, as one might expect, they generated massive amounts of vibration, which degraded print quality.

Szturc devised a truly ingenious solution to the vibration problem, which he describes in detail in this introductory video:

In the video you’ll see this machine in action running at full speed. The print samples are of exceptionally high quality when you realize how fast they were produced.

In short, THE 100’s design is highly focused on the machine’s center of gravity. Szturc carefully placed heavy components in balanced positions throughout the design. This approach actually significantly reduces vibration and thus allows the motion system to run at the highest possible speed, even though the machine’s frame is not made of rigid material.

Szturc believes THE 100 is in fact the fastest 3D printed frame entry on the #speedboatrace leaderboard.

My suspicion is that the “center of gravity” design approach will now become common practice among DIY high-speed 3D printers, thanks to Szturc’s ingenuity.

Yesterday Szturc built a second THE 100 device in an eight-hour online session that garnered a huge number of viewers. It’s certain that there are many people now building their own THE 100.

You can build one too, as the plans are published online in GitHub. Please note that there are no official assembly instructions, just the plans, so you’ll have to determine the build approach yourself.

Projects such as THE 100 prove that it should not cost a great deal of money to produce very high-speed 3D printers. I suspect this will have an effect on 3D printer manufacturers of slow devices, as they will soon face competition from inexpensive high-speed 3D printers.