I’ve been thinking about a new concept for designing 3D printed buildings that just might change the way we work and live quite a bit.

Let’s first reflect on how 3D design tools for mechanical parts evolved. At first the same tools used for conventional designs were used — that was all that was available for engineers.

Over time CAD software gradually added features related to 3D printing, and design experiences improved.

Eventually something called “generative design” appeared, which was radically different from then-current CAD tools. Instead of building up the object piece by piece, generative software “grows” the geometry using iteration.

In generative systems the “designer” merely specifies the constraints on the system, including fixed points, forces encountered, gravity, etc. Once all those are input, the system iterates designs that eventually converge on a 3D model that achieves all the objectives.

However, the resulting design will almost certainly be incredibly complex and have an unusual appearance. Normally such geometries would be pathological for conventional manufacturing gear, but complex designs are no issue for 3D printers. In this way generative design truly leverages the technology.

Back to construction 3D printing.

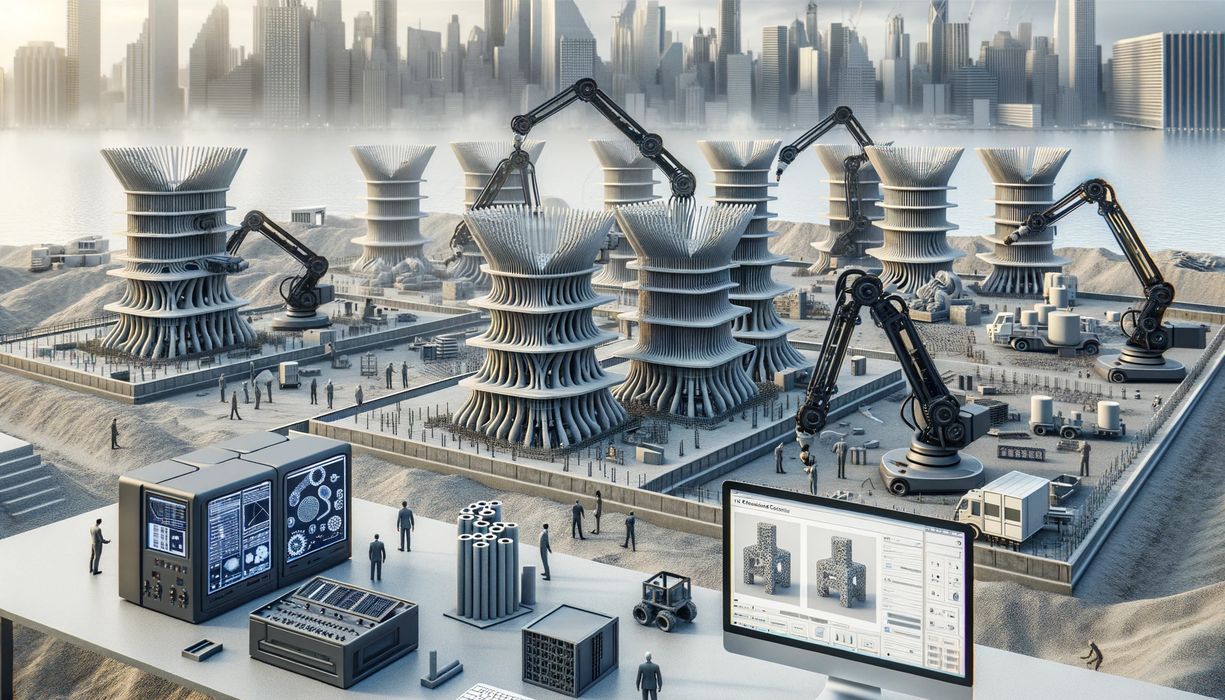

In recent years there has been quite an increase in development of what I like to call “construction 3D printers”. These are robotic devices that have toolhead that extrude speciality concrete materials. By using the same principles as desktop FFF 3D printers, these construction 3D printers can quickly build large concrete structures outdoors.

This is all good, except for one thing: the designs for these buildings is almost always very conventional. The resulting buildings look like they were NOT 3D printed.

Perhaps this is done for future sales reasons: would someone buy a weird building when they’re just looking for a home to live in?

I think the problem is more basic. I suspect none of the usual building design tools are able to properly leverage the technology’s potential, much like older CAD tools were unable to leverage the geometric possibilities of 3D printing.

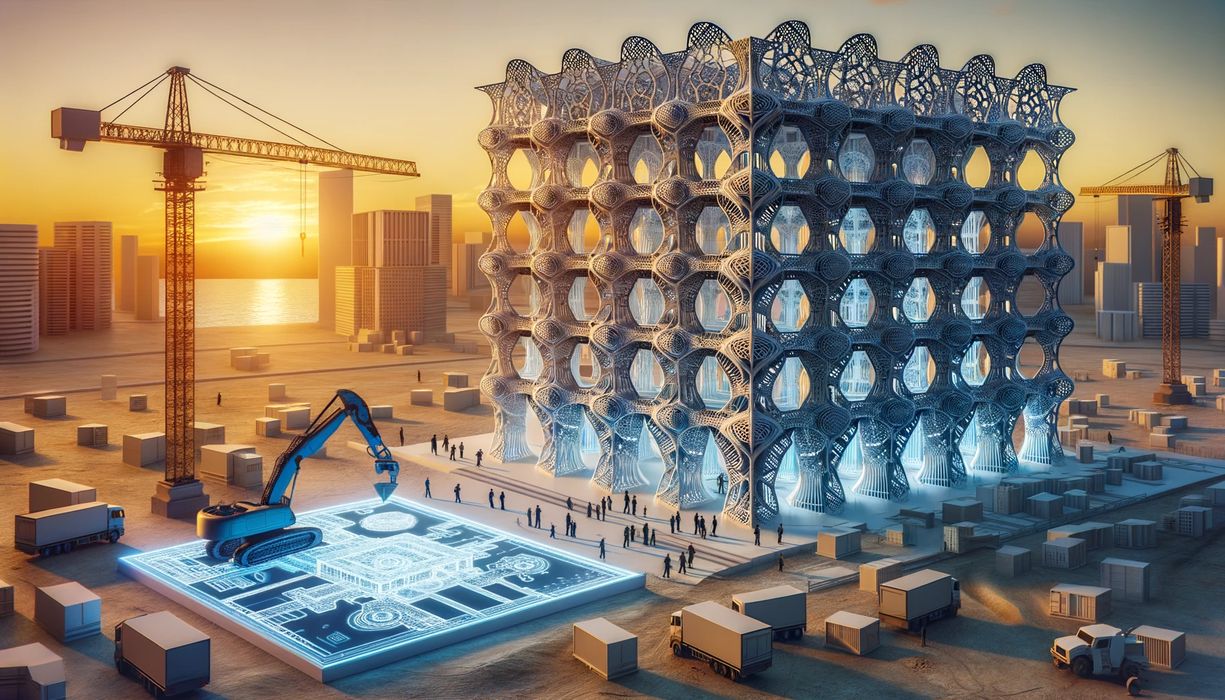

Then it occurred to me that it might be possible to develop a generative CAD tool specifically for building design.

This hypothetical tool would operate in a similar way: the designer would specify a number of constraints and objectives, and the system would iteratively grow a 3D solution.

The constraints would certainly be quite different than you’d find in generative systems for mechanical parts. You’d instead find factors like pathway minimum dimensions, footprint area, plumbing conduit requirements, insulative properties, disabled access, etc.

They are different, but the process would be the same: iterate over random variations until a solution evolves. Goals could focus on keeping costs to a specific target, maintaining exterior dimensions or building height.

If such software existed, it would surely generate the most unusual building designs — all of which would be by definition printable with current construction 3D printers.

Perhaps these generated designs might not appeal to the public. If so, then that’s not a failure of the approach, it’s merely pointing out that some additional constraints are required.

No such software exists as far as I can tell.

But it should. Construction 3D printing needs it to grow further.