Researchers have identified a method of 3D printing cellulose aerogels with greater strength.

Cellulose is a very common polymer, perhaps the most prevalent on the planet. It’s the major component of many plants to provide structure. As an added benefit it is naturally decomposable: it can be thrown away into the environment without any concerns.

Aerogels are a highly unusual material. They are lightweight because they are almost entirely made of air. They provide significant insulative properties, as well as being lightweight.

Cellulose aerogels combine the two materials to create highly useful objects that are biodegradable. However, there’s a problem: when 3D printed they are mechanically weak.

It turns out that the issue relates to the microstructure of the printed aerogel. The microstructure isn’t sufficiently strong to provide overall strength to the 3D printed parts.

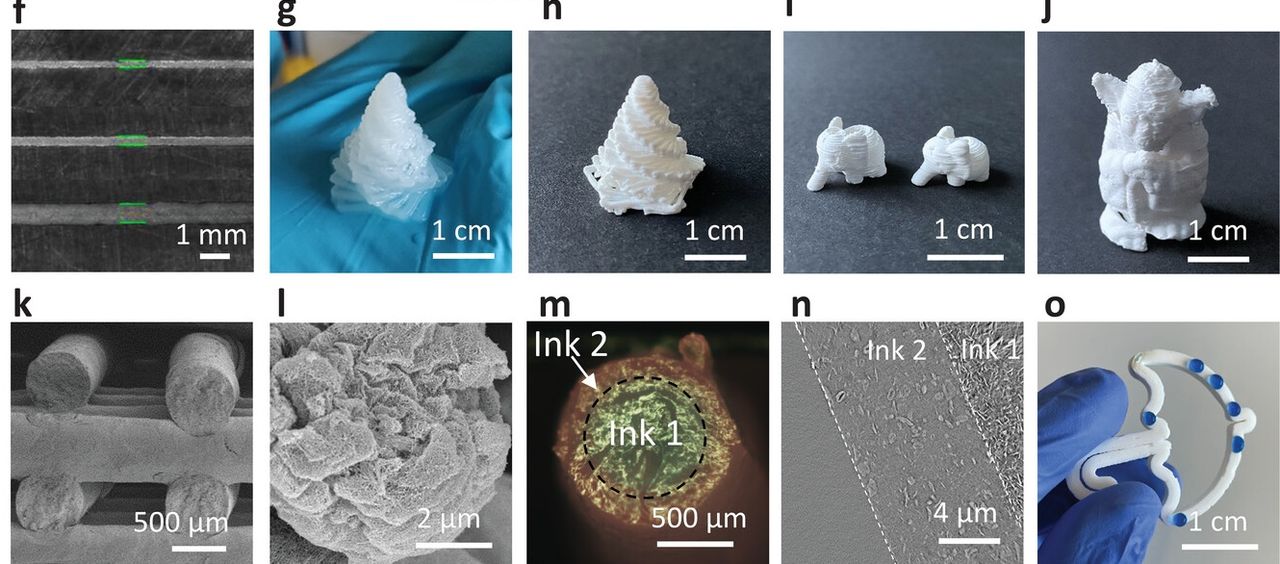

The new research has identified a way around this issue. By using a direct write 3D printing approach, as opposed to SLS or FFF processes, the researchers were able to mix carbon nanofibers of different lengths into the material prior to printing. When the resulting concoction was printed, the test parts exhibited far greater strength.

The carbon fibers use in this experiment were far smaller than those used in carbon fiber 3D printer filament. Here the fibers were measured in nanometers, ranging from 150-250nm. That’s 0.00015mm, extraordinarily small.

The researchers found that this geometry of nano fiber would tend to clump together, and that’s where the strength is derived from. In fact, they found that the resulting prints overcame traditional layer boundary issues. They explain:

“The printed samples display anisotropic properties caused by the directional arrangement of the gel structures during the printing of structural features on different length scales.”

They conclude:

“The combined CNC and CNF inks demonstrate superior, stable, and consistent printability for direct ink writing of anisotropic, pure cellulose hydrogels and aerogels. The water-based inks and convenient Ca2+-induced gelation open a broad printing window for large and complex geometries.”

And:

“The 3D printing technology is a versatile and scalable approach to fabricating cellulose aerogels with tailored properties and geometries for a wide range of applications, especially in thermal insulation and biomedical fields.”

It seems we may have a new 3D printable material for new forms of applications.

Via Wiley