Researchers at TU Chemnitz have developed a unique method to produce temperature resistant housings for electrical applications.

This same research team has been investigating this niche of 3D printing for several years. In 2018, the team developed a functional 3D printable motor, which used both ceramic and metal pastes. This electric motor was able to withstand operating temperatures of 300C.

But there was a problem: if you really were 3D printing an electric motor, you’d definitely want the device to include the required electronics mounted on the outside of the motor. However, these could not withstand such high temperatures.

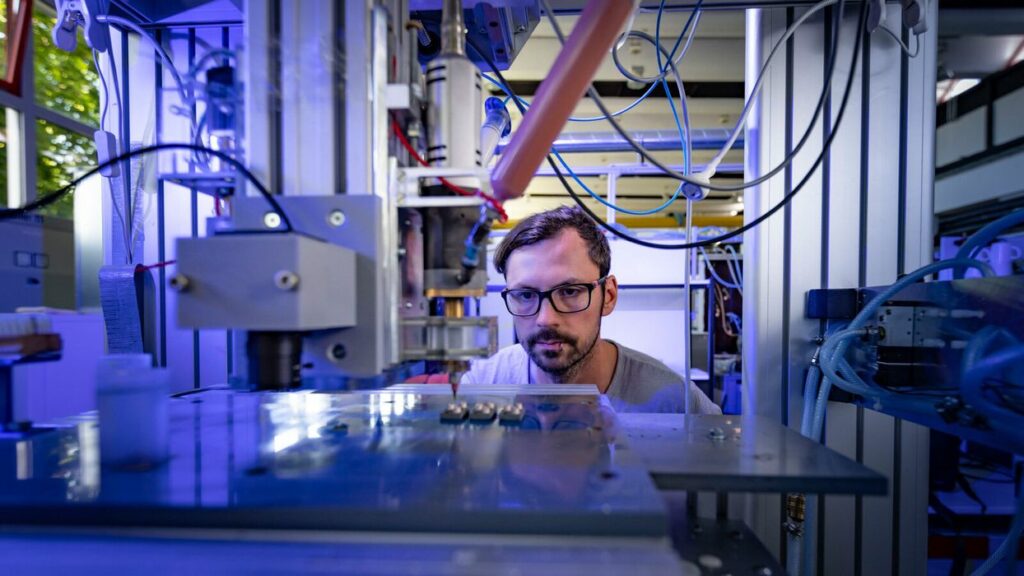

The new research has developed a method of 3D printing housings that potentially could fit onto a 3D printed electric motor or other high temperature electrical applications. The concept is to 3D print a ceramic housing, but insert the required electronic chips during the print. The ceramic material will insulate the chip from both electrical interference and heat. Copper is also used to provide connectivity to the embedded electronic chip.

Professor Dr. Ralf Werner explains:

”These are sintered after the printing process, together – and this is what makes them special – with the imprinted chip. The desire for more temperature-resistant power electronics was obvious, because the housings for power electronic components are traditionally installed as close as possible to the engine and should therefore have an equally high temperature resistance.”

The approach is also useful beyond just thermal and electrical insulation: the ability to 3D print the housing meant the researchers could experiment with complex surface designs that could be far more efficient for cooling the motor.

This is a very unusual experiment and I’m not sure where it could go. Would there really be a market for 3D printed electric motors? There could be, if efficiencies of the resulting motor were sufficient, but that’s unlikely. It may be that this technology may prove more useful in remote locations where delivery of traditional electric motors could be challenging: like on a Moon base, for example.

Via TU Chemnitz