Researchers have developed a new method of removing toxic metal pollutants from water using a 3D printed technique.

Metals are a material we use every day, but many are quite toxic if exposed to the body in certain ways. One of those ways is through water contamination: water enters the body through food, drink or skin exposure, and if there are contaminants, they also enter the body. Over long periods of time these metals can accumulate and cause multiple types of damage.

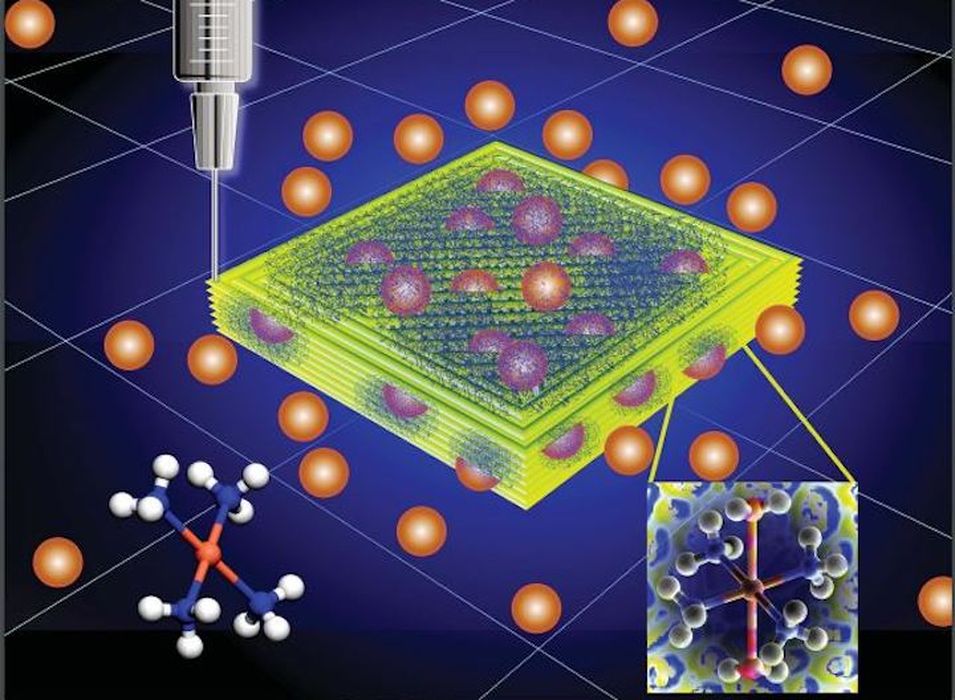

The researchers were able to create a 3D printable “ink” that was composed of alginate, gelatin, and polyethyleneimine (PEI). PEI is frequently used in 3D printing as a material and print surface, but here it’s contributing to a different application.

The researchers were able to 3D print geometrically complex hydrogel “tablets” that contain the materials above. These tablets were designed to exhibit maximum surface exposure, and could be used by depositing large quantities of them into affected water.

The geometry of the tablets is designed to expose the key ingredient materials to passing water, where they can bond with the undesirable metals.

The researchers found the new approach was quite successful. They explain:

“The results demonstrate the contribution of hydrogel composition and rheology in determining the printability, stability, and heavy metal binding characteristics of the hydrogel, and indicate the critical role of the PEI in increasing stability of the printed construct, in addition to its metal binding properties. The highest removal capacity was obtained for copper, followed by cadmium, cobalt, and nickel ions. In the optimized formulation, each hydrogel tablet removed 60% from 100 ppm copper in 5 h and up to 98% in 18 h. For more concentrated solutions (1000 ppm), ∼25% of copper was removed in 18 h.”

This is quite interesting, particularly because the tablets can be produced with inexpensive ingredients and at scale.

They also found that they could “tune” the tablets’ function to allow for different types of metal adsorption.

Professor Silvana Andreescu explained the project:

“Our work demonstrates unique capabilities of green and sustainable materials to be additively manufactured and designed so that they have the ability to capture and remove toxic contaminants, providing innovative solutions for next-generation detection and remediation technologies. This work contributes to the development of materials and methods for environmental monitoring and clean up to achieve the global WHO goals for clean and sustainable water.”

This is a fascinating example of applying 3D print technology to a real-world problem. If this is commercialized, one could see equipment to produce this type of tablet set up at water processing facilities, where they could produce tablets for many different forms of contamination on demand.

Via RCS and Clarkson University