Rocket-maker Relativity Space is about to collect a whopping US$500M in a Series D raise.

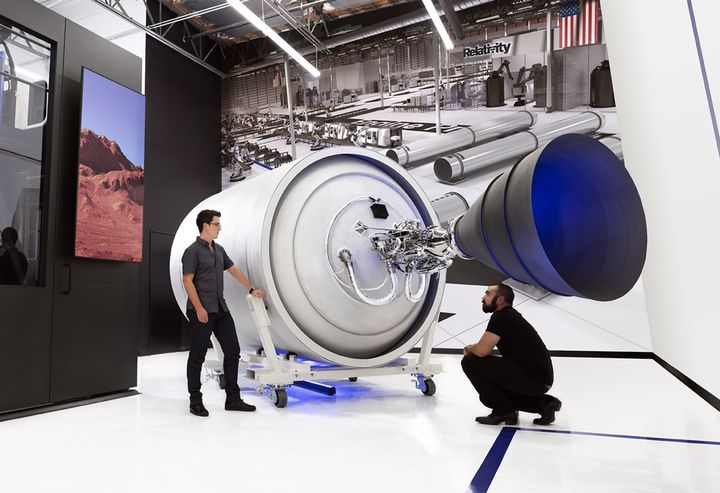

The California-based company is notable because their approach to building rockets is entirely different than any other provider: they are 3D printing them from top to bottom.

To do so, Relativity Space has designed their own custom metal 3D printer, a device they appropriately named the “Stargate”. This is not a standard cartesian-style PBF machine, but instead is powered by a very large robotic arm system.

While they have not yet flown any rockets, 3D printed or not, the concept appears very promising. It’s so promising they have attracted a number of increasingly large investments and contracts from interested parties.

They’ve made two announcements recently about secured clients, including Lockheed and Iridium. They’ve spent US$59M building a new factory to house Stargates and production facilities. They received an investment of US$140M recently, too.

With the announcement of this latest investment round, the company valuation is now a staggering US$2.3B, surely one of the highest-valued companies betting on 3D printing technology.

The new cash will be no doubt used to scale up operations to meet customer demands and prepare for their first launch. TechCrunch says:

“The $500 million round would presumably be to scale operations in earnest, gathering the personnel, materials, transportation, insurance and other necessaries for taking on major missions. Terran-1 hasn’t flown yet, but the projected costs and cadences make it a very attractive option, larger than Rocket Lab’s Electron but smaller than a SpaceX Falcon 9 — and pound for pound, maybe more cost-effective than both.”

The big test will come some time in 2021, when Relativity Space will perform their first launch of the 3D printed rocket, Terran-1.

Should it succeed, we’ll see a confirmation of the use of 3D print technology like no other time in history. Other companies and industries will see what Relativity Space has achieved and they’ll try to replicate that success in their own worlds.

From top to bottom, we may soon see a lot more entirely 3D printed products.

Via TechCrunch