Having used many types of 3D printers for so many years, I’ve heard all the hype. But what are the hidden truths?

We’ve all seen the glossy brochures and fabulous web pages glorifying the latest 3D printers and their amazing technologies. They are indeed amazing. Massive progress has been made over the past decade, and there’s never been more powerful 3D printers available at incredible price points.

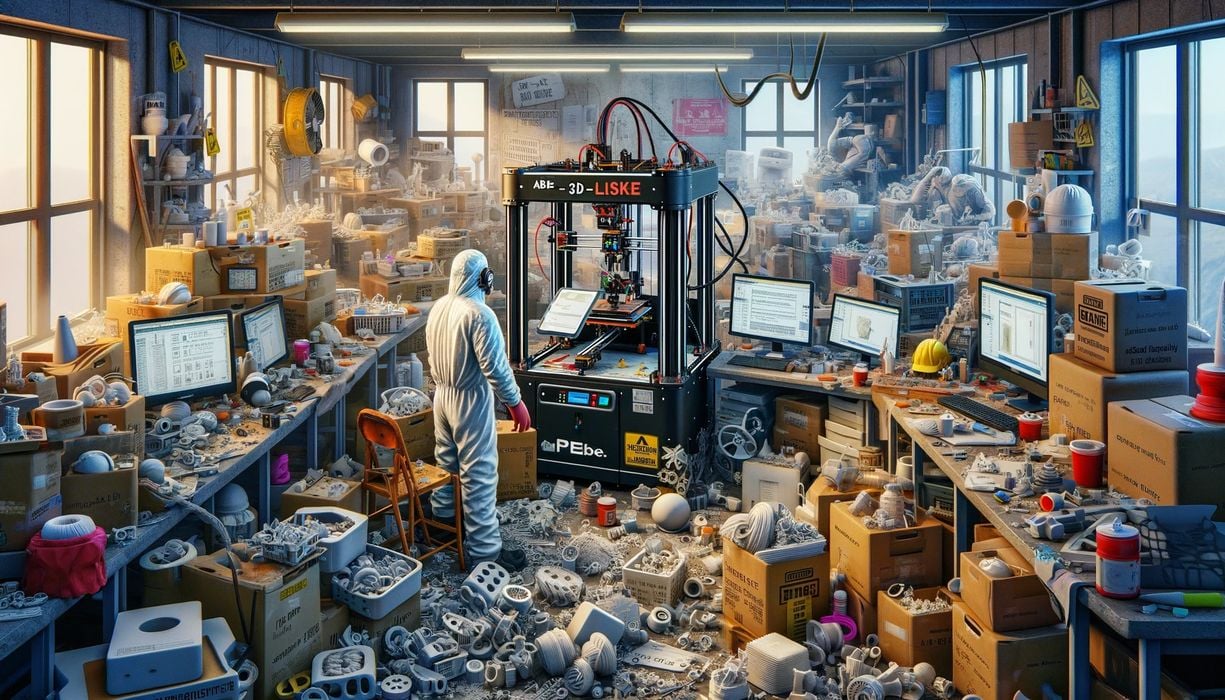

But there’s a hidden downside that is almost never described. Let’s take a look at some issues that may surprise new 3D printer operators.

There’s a Right Tool for the Job, Except When There Isn’t

The public’s notion of 3D printers are that they are some type of magic replicator that can reproduce any given object. The truth, however, is that all machines use different processes that are most appropriate for certain kinds of objects. The rule of thumb is to choose the right tool for the job. But in some cases there is no tool, because the nature of the object and required material simply cannot be 3D printed.

At least, not yet.

That Material Isn’t Available

When producing prototypes and certainly end-use products, specific materials are required for environmental, regulatory, or functional purposes. That material had better be available for use on a 3D printer, or you can’t produce your item. “ABS-like” material is not ABS. You may have to compromise your engineering decision in order to print an object.

My Machine Broke, Again

3D printers are still not as reliable as most appliances. Paper printers are quite reliable, and the public has come to expect that level of reliability with their 3D printer. Except that these machines still break frequently. Sure, they break less than they used to, but virtually every machine will require fixing sooner or later. It’s always best to ensure your supplier can provide spare parts.

My Machine Is Obsolete Already!

An effect that is happening in recent years is a rapid take-off of technology. Features and pricing are incredibly advanced and the pace of change is changing quickly. In other words, that machine you acquired five years ago is now basically worthless. The machine you buy today might be worthless in a year or two.

There’s a Lot More Work Than I Thought

Making a 3D printed object is pretty easy: hit the print button and wait. Hold on, there’s more to do, sometimes a lot more: you must post process your print. The type of post processing varies depending on the type of 3D printer used, but all of it takes time, tools and patience. Even if a 3D printer is very fast, you may still have to spend a ton of time cleaning up the print afterwards. Print speed isn’t everything.

That Material is Toxic

Most resin 3D printers are typically unsafe because they use toxic resin that could be exposed to the operator. It is possible to use them safely if one takes a number of precautions, including use of PPE, however, I fear many people don’t. It’s troublesome and tedious to use these machines safely, even though they can produce outstanding print quality.

I Have To Learn CAD?

Printing objects is easy, but where is the content to be printed? 3D models may be found online in a number of increasingly complex online repositories, but most often you cannot find exactly what you want, or you are baffled by poor search capabilities. Eventually you will realize that you will have to learn a CAD software tool in order to design your own parts. This is quite challenging (and sometimes expensive), and some people are just not up for the task for a variety of reasons.

Those are seven hidden truths of 3D printing. Did I miss any?