Raise3D announced an upgrade kit for their Pro3 series that dramatically increases print speed.

The company previous released a high speed 3D printer, the RMF500, about a year ago. This device included a number of features, not the least of which is a very rigid frame.

While this device was quite successful, Raise3D engineers pondered whether some of the techniques used on the RMF500 could be used on the company’s flagship 3D printer Pro3 series. It turns out that indeed, some of the features could be used on the Pro3 series platform to greatly increase print speed.

Increasing print speed is a rather tricky business. While it may seem easy to simply adjust the print speed setting in the slicing software from, say, 50mm/s to 300mm/s, it isn’t quite that simple.

When printing at extreme speeds motion issues arise. For example, the momentum of a flying toolhead must be handled when changing direction. This common move can introduce shock waves into the toolhead, motion system and frame. If not accounted for, the result will be bouncy echoes in the print referred to as “ghosting”. In extreme cases the toolhead could even slip and land where it isn’t supposed to be, wrecking the print.

Another issue is thermal. As filaments pass through the hot end, they absorb heat and soften. However, in a high speed printing scenario the filament and material move through the hot end more quickly, leaving far less time for heat absorption.

To counteract this, high speed printers usually change the hot end to increase the time of heat absorption and achieve the required softening.

Some manufacturers even require specifically designed filaments that soften more easily, and thus are easier to print at high speeds.

Raise3D Hyper Speed Kit

The Raise 3D Hyper Speed Upgrade Kit for Pro3 Series 3D printers makes changes to a Pro3 series 3D printer to enable all this to happen.

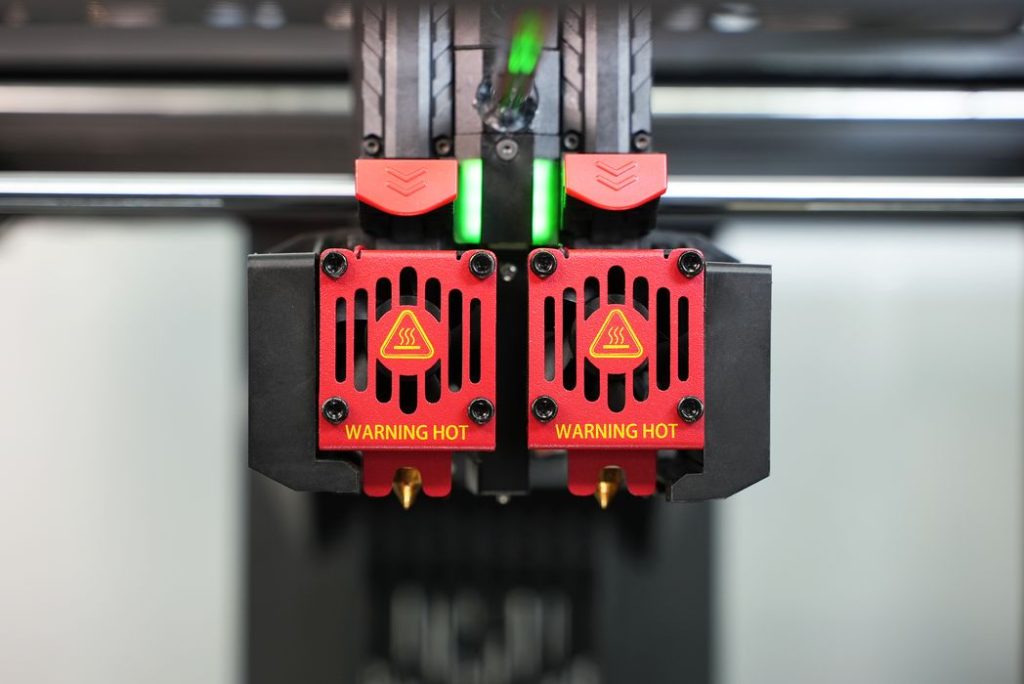

The kit includes replacement hot ends that (presumably) heat up the material more quickly. The kit also includes a “smart auto frequency calibrator”, which isn’t quite explained. I suspect it’s a system for ensuring the system can actually operate properly at high speeds.

Along with this hardware, the kit includes a software upgrade, which makes a lot of sense: the firmware in the Pro3 series device would have to process far more movements per second than in standard print mode, and there’s likely special software to do that. Raise3D said the new system is able to process more than 600,000 steps per second, which is quite impressive.

The kit includes a spool of ABS and PLA from the company’s new “Hyperspeed” line of materials. These are thermally designed for high speed use.

Raise3D said a Pro3 device equipped with the “HUK3” upgrade can print 3-5x faster than typical 3D printers, with a deposition rate of up to 28 cubic mm per second. Print speeds range from 120-250mm/s (for the shell) and 200-350mm/s (for the infill). An upgraded machine can 3D print up to 1kg of material per day, which is amazing.

What’s even more incredible is the pricing for this upgrade.

The kit itself will retail for US$999, but anyone already owning a Pro3 device (or even buying one before the end of the year) is able to acquire the HUK3 kit for only US$699.

You could say that this price is high because you’re buying a couple of specialized hot ends. But another way to look at it is that your Pro3 machine would be able to print almost 4X as fast.

In other words, the price of this upgrade effectively buys you another THREE PRO3 MACHINES.

That’s a pretty good deal, if you ask me.

Via Raise3D