This week’s question relates to a rather old 3D printer, the ideaPrinter F100.

Reader Mario asks:

“Hi, I have an IdeaPrinter F100 since 10 years agó. but sadly, today one simple static current spark from my own hand fried some circuit and stops working, I wish to replace the electronics of the printer, can you help me with that?”

Let’s start with the basic “what is an ideaPrinter F100”?

This is rather old FFF 3D printer with build volume of 305 x 305 x 175 mm, and used 2.85mm filament. It was produced by “FusionTech”.

“FusionTech” is short for “Shanghai Fusion Tech Co.”, which today is more well-known for their popular professional 3D printer brand, “Raise3D”.

Note that Raise3D’s current advanced slicing software is called “ideaMaker”, originating from days gone by when their product was the ideaPrinter.

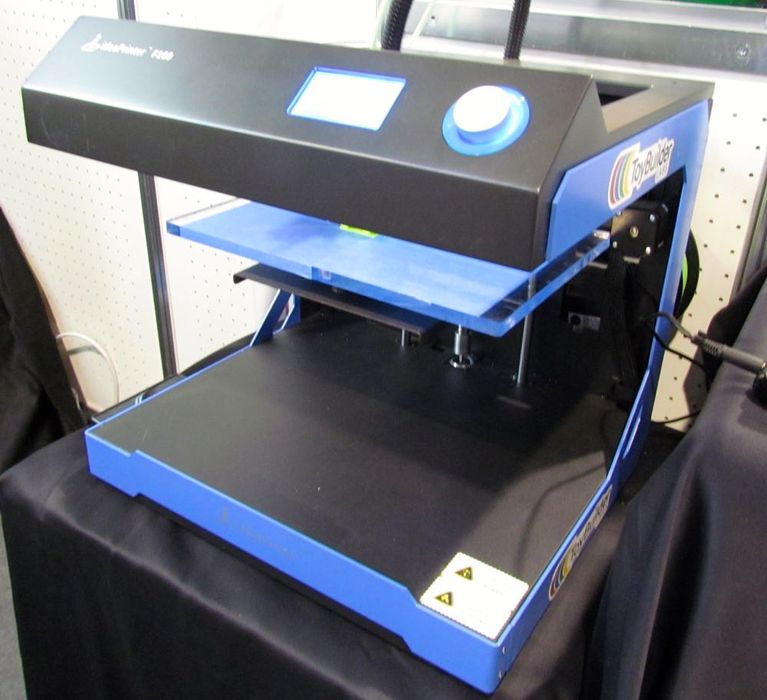

We first ran into Shanghai Fusion Tech Co back in 2015, shortly after the company’s founding. Then their flagship 3D printer was indeed the ideaPrinter F100. We saw that exact model, as shown at top.

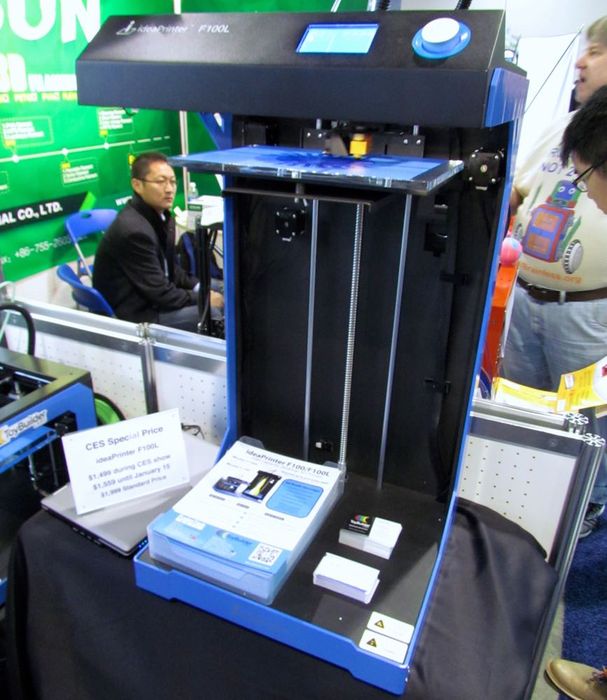

We also saw the “stretch” version of the same machine, the F100L.

As this machine is now about ten years old, it’s not surprising that Raise3D no longer supports the device. A look through Raise3D’s community online forum shows they last posted firmware for the device six years ago, and they don’t even have categories for discussing the ideaPrinter anymore.

As for replacement electronic boards, they don’t sell them, either. This is actually not surprising at all, because this is a very old machine in a market that has been very rapidly changing over the intervening years.

There are two ways to get a working board.

First would be to find a board from a third party. Of course, a quick search indicates there are none for sale. A second approach would be to purchase a second ideaPrinter for parts. Ideally, that would be a low-priced unit that has something else wrong with it, but does have a working board.

I did a quick search through eBay and other places, and found no such machines for sale. So it appears this approach may not work, unless you are extremely lucky to find one at an estate sale.

A second way to get the board working might be to have an electronics specialist take a look at the board and possibly repair it. It may be that a simple component, like a capacitor, might be burned out and could be replaced. On the other hand, a chip might be fried, and you may not be able to find a replacement. In either case, you’d better have a good electronics friend with interest in fixing the board for fun, or be prepared to pay a professional to do so.

But then this is where the financial equation comes in. The cost to replace or repair the broken board could be a few hundred dollars. If that’s the case, then it may be a better strategy to simply toss out the old printer and get a new one.

If you look closely in the image we took of the ideaPrinter F100L, you’ll note that the price of this machine was at that time US$2,000. That may seem pricey now, but back then it was probably typical for that type of device.

Mario, you may be thinking that this machine’s value is still in that range, but it is not.

Yesterday’s US$2,000 machine is actually far, far less functional than today’s US$300 machines. Today’s desktop 3D printers:

- Are far less expensive

- Print far faster

- Print with far, far better quality

- Are significantly more reliable

- Have many extra convenience features

- Can connect to clouds for remote operation

- Are much easier to maintain

- Have infinitely better (and heated) print surfaces

- Are far easier to operate

- Use the more popular 1.75mm filament

- Can handle far more interesting materials

- Are more fun

To me, there is really no reason at all to keep using the ideaPrinter F100, even if you could fix it. As long as you are able to afford a few hundred bucks, you can have a massively better machine on your desk. Good options might include the Creality Ender-3 or Anycubic Kobra product lines. These devices often come on sale when new models are released, so they can be quite inexpensive, as low as US$200 or even less.

My recommendation is to give up the ideaPrinter F100 and move on to a more current machine. I’d say you got your money’s worth from the F100 over that many years, it deserves a rest.

Via Aniwaa

It wouldnt be too difficult to replace the board and Screen(if needed) to an after market 3d printer control board. A BigTreeTech board would only cost around $50, and then you could cook your own firmware for your machine. There are alot of free tutorials on how to do it. If you really enjoy using that machine I would suggest that. As for getting more precision, you should be able to do that through firmware or with stepper motors with smaller steps but most stepper motors already have a 1.8 degree step and support micro stepping. Just make sure that if you get an aftermarket board, that it supports micro stepping to the degree that you want I.E. 16,32,64,128,256 steps