This week’s question is about how one might go about operating an ancient 3D printer.

Fabbaloo Reader Paul writes:

“I have acquired an Originator i1. I have gotten it working. Was curious if there are any resources for information on details of operation of this unit?”

The “Originator”? Is this a real device? I don’t seem to recall it, but then I’ve seen literally hundreds of 3D printers in the past decade.

Hold on, we have a post about this device, written way back in 2014, making the Originator an eight-year old device!

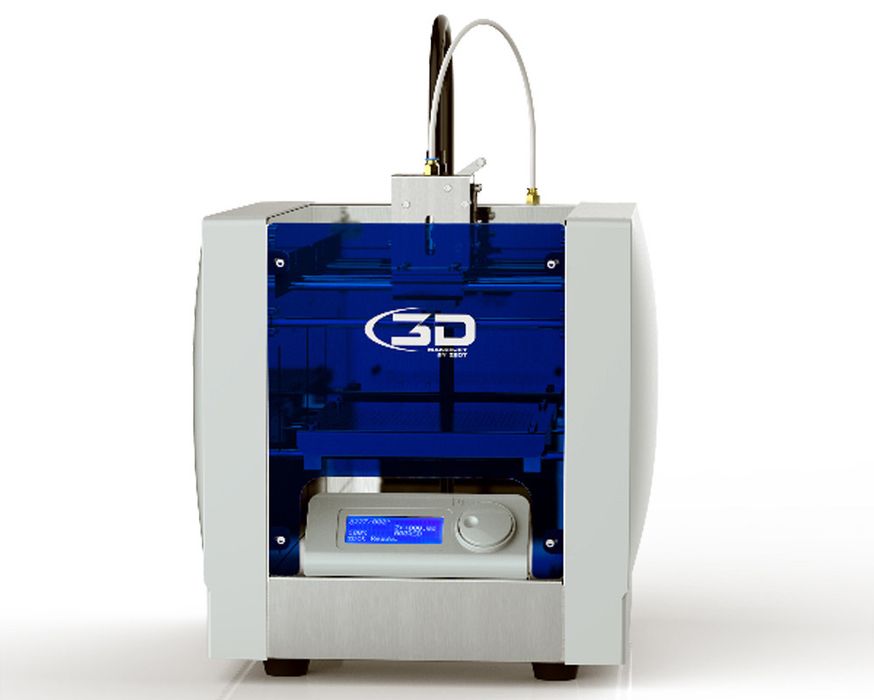

The Originator was produced by Orlando-based

3D MakerJet, which now seems to be defunct after being founded in 2009. A scan through the Internet archive shows the site began having server issues in July 2016, with the last seemingly active site capture on 22 June 2016. Since then all captures of the site are errors or “parked domain”. Evidently the company shut down sometime in 2016. The most recent press release is from February 29th, 2016. This means they were active for only about two years.

An examination of their most recent financial postings showed the company basically ran out of funds after being unable to sell a sufficient amount of equipment, and subsequently folded up with an accumulated deficit exceeding US$1.2M.

During this period it was all too common an occurrence, and the landscape is littered with machines produced by eager startups that got caught up in the 3D print consumer frenzy of 2014. Later that year it all came crashing down as everyone realized the machines were simply too hard to operate for general consumers, and without a clear use case, there was nothing to sell. Apparently 3D MakerJet fell into this category, while a few of their competitors successfully pivoted into educational or professional markets.

During their operational time 3D Makerjet produced a number of devices, including the Originator i1, i2, 20 and 35. They also announced an upcoming metal 3D printer that used a wire feed system, which evidently never hit the market.

The Originator i1 is a FFF 3D printer, with a rather tiny build volume of only 150 x 150 x 140 mm. Constructed in steel and plastic, the system included a 250W power supply and a heated print surface. Full details are still stored by the Internet archive.

Unfortunately, 3D MakerJet apparently never published an online support manual for the Originator i1, so it could not be captured by the Internet archive. However, they did publish an FAQ page that can be seen here.

The FAQ page answers basic questions like, “how do I clean the extruder nozzle”, and similar. This could be helpful for someone looking to get an i1 working, but it has only basic answers.

Paul, you’re very fortunate that the device is still working. Many devices of that age simply won’t power up or have issues with the motion system due to inactivity. Having it print at all is quite a lucky situation.

More than likely, it operates in the same manner as many 3D printers of that era did, and still do today. Anyone with good familiarity with FFF 3D printers should be able to run jobs on the machine.

For software, the key is to develop a configuration to prepare jobs for the Originator i1. This can likely be done using Ultimaker Cura or PrusaSlicer, but will require manual configuration of the machine. The tricky part will be figuring out the starting and ending GCODE, but again this can be done through copying existing scripts for other machines and adjusting after careful experimentation.

My searches have found zero online resources for this device, or any of the 3D MakerJet devices for that matter. This is an old device that has faded away from the memory of the Internet.

That said, someone with familiarity with FFF 3D printers is almost certainly able to work with the device as it would use understandable components. It would be possible to make simple fixes and tuneups if an experienced person were to get their hands on the device. Paul, you might want to reach out to your local makerspace to see if such a person is available to give you some advice after looking at the machine.

The real problems will occur when the machine inevitably breaks. It could be a belt, motor, circuit board, power supply or other key component. Should that happen, you’d have to source the replacement yourself and after this much time it may not be possible to do so.

One approach for spare parts might be to attempt to obtain a second i1, even one not working, so that it could be pillaged for parts when necessary. That is your best approach for spare parts. eBay might have something come up eventually.

However, I do question the value of even attempting to work with the i1. Unless you’re into 3D print history and have fun with the challenge of getting a “heritage” machine working that no one else has, it’s likely better to simply get one of today’s new machines.

There are plenty of quite powerful devices available at low cost — even US$299 — that would run rings around anything the i1 can do. They will be more reliable, supported, bigger, faster, produce better quality prints, and be much easier to operate.

I have several ancient 3D printers in my possession as well, including one of the original MakerBot CupCake machines. But none of them operate, nor do I want them to; they are now museum pieces, and I suspect the i1 is in that category, too.