Quantica has raised a massive €14M in funding to power development of their unique NovoJet 3D printing technology.

The Berlin-based company, founded in 2018, hopes to shake up manufacturing with 3D printing through the use of a new printing technology they call “NovoJet”.

NovoJet: High-Speed Inkjet Printhead

NovoJet is a kind of inkjet printhead, reminiscent of those used in several high-volume 3D printing systems. These systems can be used to build very high-speed printing systems because the inkjets are able to deliver material in parallel at very high rates.

The way to visualize this is to imagine a high-speed 2D printing press, where the paper is flying through at great velocity, and a full row of inkjets is frantically dropping ink where required. Now imagine doing that layer-by-layer to form 3D objects.

That’s why inkjet systems are able to print so quickly.

Overcoming Viscosity Challenges

But there’s a problem: in order to get the ink to flow smoothly and quickly through the microscopic nozzles, the viscosity of the fluid must be quite low. Higher viscosity fluids would quickly clog up the works.

That, in turn, causes a major issue: high viscosity fluids are the most useful because they can be denser and ultimately provide for superior 3D parts. In other words, many of the inkjet-style 3D printing systems don’t produce particularly useful parts.

Enter Quantica’s NovoJet technology. Novojet is an “ultra-high viscosity” print head, with an incredible viscosity range of 1-400 mPA.s, emerging from a row of 96 nozzles per printhead.

Quantica said this system allows for the use of true high-performance and functional additive materials, all while printing at high speeds.

Quantica’s Progress and Future Plans

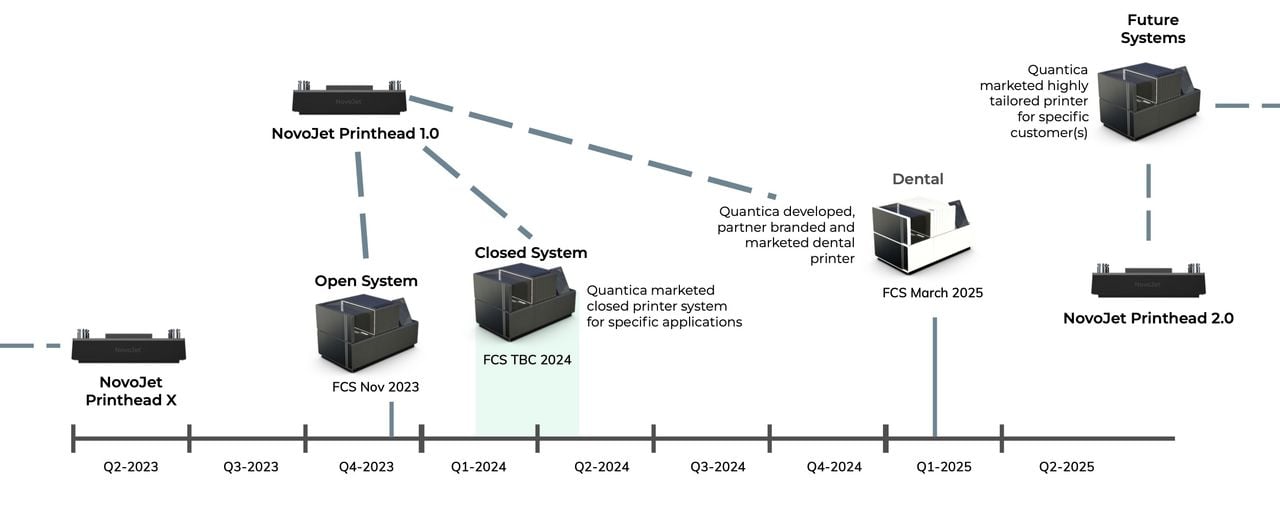

The company’s work is still in progress. While they have completed development of the NovoJet printhead, they now have to build a 3D printer around the concept.

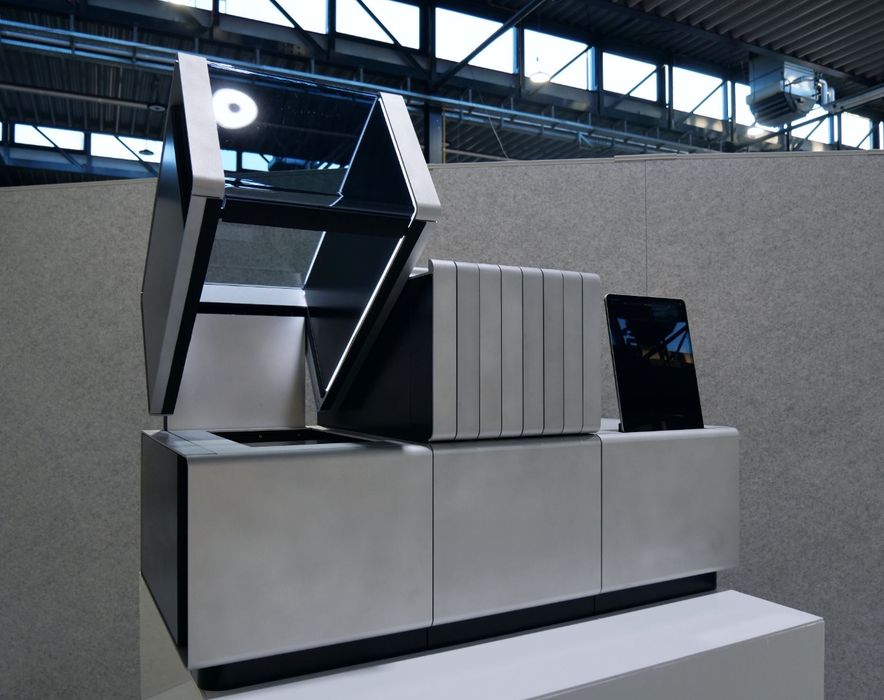

So far they’ve produced a prototype device, the NovoJet C7, which was publicly shown last fall. This device was able to accommodate up to seven print heads, demonstrating the scalability of the process.

Quantica hopes to release their first commercial system towards the end of the year, and apparently this will be an open development platform. This will be followed by a “closed system” sometime in 2024.

It seems the company will spend considerable time over the next while developing and testing a variety of functional materials that leverage the NovoJet technology. These will be tested among a set of partners in various industries.

Potential Applications for NovoJet Technology

Quantica foresees a long list of potential 3D printable applications for NovoJet, including:

- Bioprinting: Controlled cell deposition with lower shear printing modes, high speed pipetting of sensitive media, bone and cartilage printing with hydroxyapatite, ceramics, polymers

- Audiology: Low leaching, MDR and ISO 10993 compliant, function integration with conductive materials, functionalized silicone padding

- Medical: Orthoses with padding, prosthetics, pharmaceuticals and drug delivery, dental ceramics

- Wearables: Polymer batteries, sensor integration with conductive and particle loaded materials, printing on textiles

- Hydrogels: Cellular scaffolding, soft robotics and sensors

- Glass filled polymer: Eyewear and lenses

- Coatings: Automotive, disinfecting surfaces

- Electronics: Emissive polymers, conductive inks, hydrogel polymer batteries

It seems clear why investors awarded the company with the new Series B funding; Quantica has a very powerful technology that could do great things.

Via Quantica