Desktop Metal has introduced a pure copper material to be 3D printed on their Studio System.

The Studio System, introduced in 2017, targets accessible metal 3D printing. The “desktop” of the Desktop Metal offerings, the Studio System has seen some notable progress over the last few years. Enhancements to both the hardware and material sides of the portfolio have taken the Studio System to more installations around the world.

Copper 3D Printing

Today, Desktop Metal has introduced an intriguing new material for its Studio System: copper.

We’ve been considering copper 3D printing as an exciting next area of focus for the industry, as more companies have been working toward viable capabilities with the material.

One of the most familiar materials over the entirety of human metalworking history, copper has presented some unique challenges to adaptation for additive manufacturing. Primarily, the metal is highly reflective. Most metal 3D printing systems use lasers — think PBF — to sinter metal powder together. That becomes much more difficult with a highly reflective powder, which would prefer a disco ball effect to a quiet acquiescence to being sintered. Copper also transmits heat and electricity very well, adding to challenges in creating a stable and predictable meltpool.

Relatively few companies today offer copper 3D printing. SPEE3D was perhaps the first major company to introduce the material. Targeting rougher applications such as the mining industry, SPEE3D’s copper capabilities are impressive — but not perhaps what every user might be looking to accomplish. Other possibilities arose from Fabrisonic’s ultrasonic capabilities.

More recently, though, copper has been appearing more frequently in more traditional 3D printing systems — and, appealingly, more affordable ones.

Markforged introduced copper to its Metal X portfolio earlier this year. Last month, Xact Metal introduced its own copper addition. Additive Drives recently debuted in Germany with some interesting copper 3D printing capabilities.

Desktop Metal Copper 3D Printing

Electrode holder

Helical heat exchanger

Bus bar

Announcing copper today, Desktop Metal joins the movement to make the metal more accessible.

The company notes of its new material that it is pure copper, explaining in the release:

“Unlike laser-based processes, which often print chromium zirconium copper, the Studio System’s proprietary Bound Metal Deposition process is able to print pure copper, unlocking the full benefits of the material.”

Proven customer applications using the new pure copper material include:

- Electrode holder for manufacturing

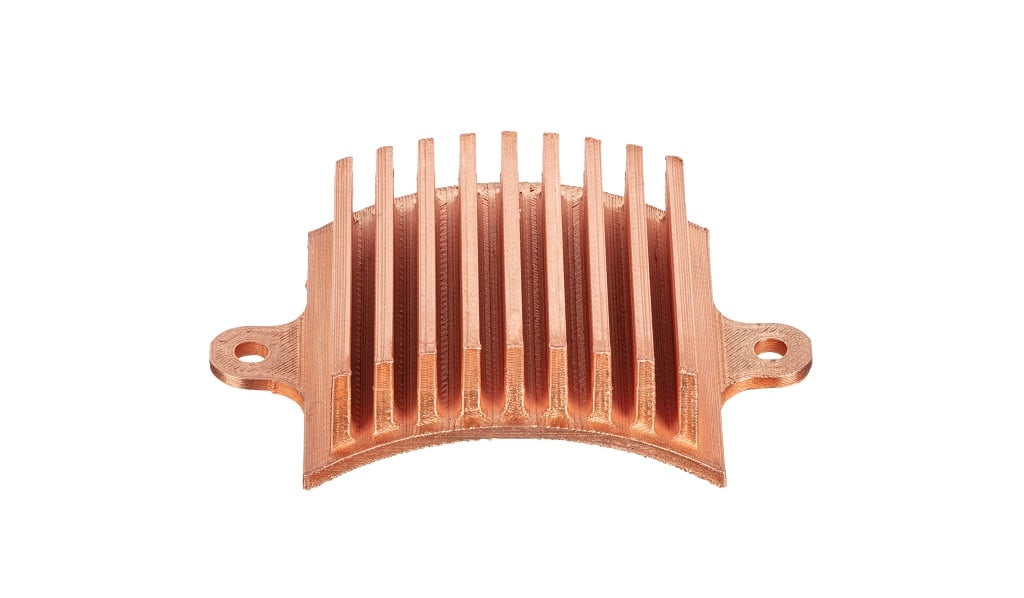

- Motor heat sink for automotive

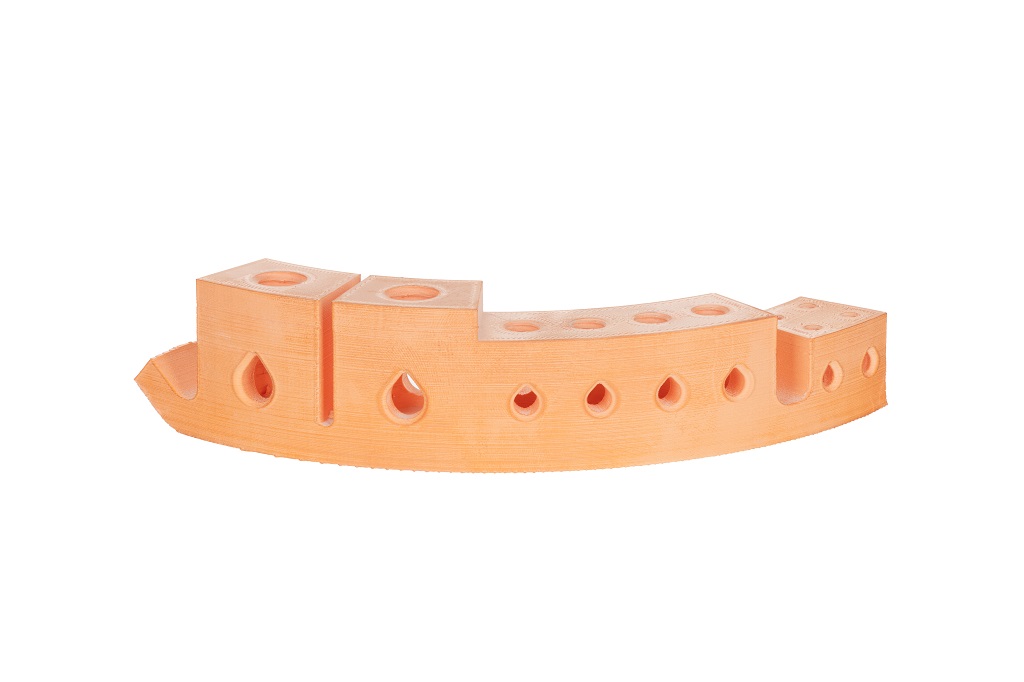

- Helical heat exchanger for chemical processing

- Bus bar for electric power distribution

These early proof points leverage the benefits of additive manufacturing — complex geometries, reduced part counts, etc. — as well as the thermal and conductive qualities of copper.

“Known for its excellent thermal and electrical conductivity, copper is a highly desired material for a variety of industries and applications, such as heat exchangers and electrical components for heavy industries to consumer products,” said Jonah Myerberg, CTO and co-founder of Desktop Metal. “Whether for heat sinks, electrical motor and power grid components, or resistance welding electrodes, 3D printed copper on the Studio System is an ideal choice for manufacturing parts featuring complex geometries.”

Via Desktop Metal