Prusa Research provided a very detailed update on their XL 3D printer development.

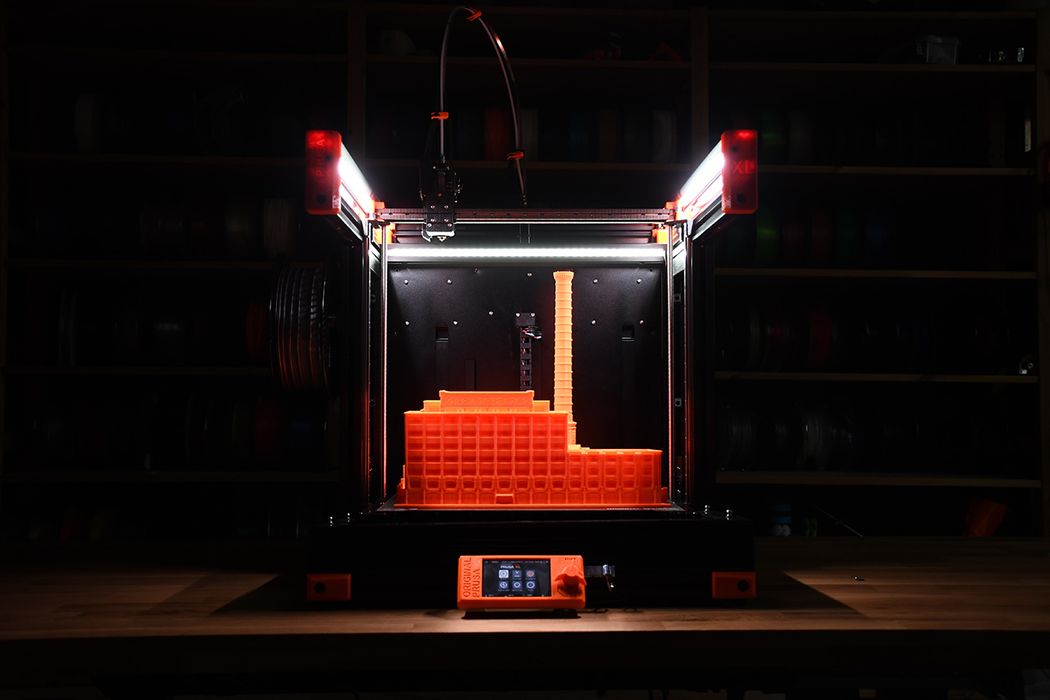

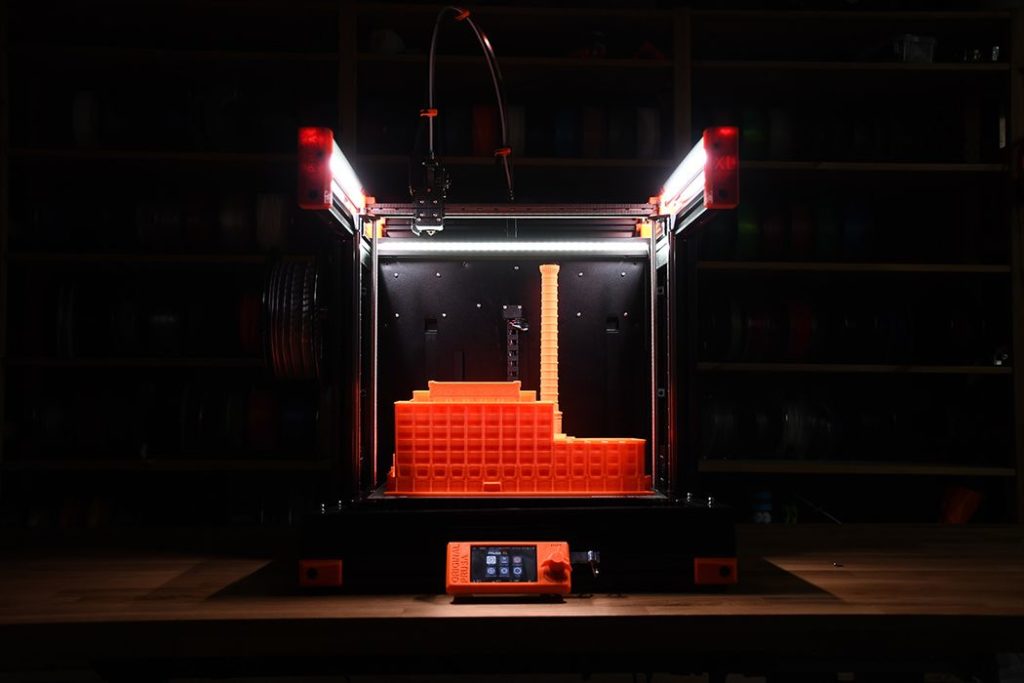

The XL will be Prusa Research’s 3D printer with the largest build volume, 360 x 360 x 360 mm. Not only that, it will also enable the use of five separate printheads for multimaterial printing, or use of soluble support for complex objects.

It’s a very promising machine that has attracted a great deal of attention. This is Prusa Research’s first foray into professional gear, and that’s a new market for the company. It’s important for them to get it right and carry their good reputation into new areas.

As is their practice, Prusa Research continued their transparency on the project with a comprehensive update that revealed more about what’s happening behind the scenes in the XL development project.

Before their update, however, CEO Josef Prusa wrote about the events happening oh-so-close to their company:

“I know these are not the best times to share a dev diary – a war is raging in Ukraine, just several hundred kilometers from our factory, and there are more pressing issues than discussing the features of a 3D printer. We’re trying to help wherever we can and once again I’m amazed by the generosity and support coming from all around.”

Product development has been a challenge ever since the pandemic began in 2020, with Prusa Research indicating two years ago they were even having issues sourcing boxes for their products. However, most of that has been sorted out, and they now focus on XL development.

Like most manufacturers, Prusa Research found short supplies of critical electronic chips that would have been used in the XL. The shortages forced them into reconsidering the chips used, and it turns out they’ve selected an alternative from their original choice. The new unspecified chip is said to be more powerful as it is a newer version of their original target chip.

The new chip includes firmware features that should streamline future updates to the XL. Apparently the chip will allow them to store machine configuration information in non-volatile memory, which can be inspected later during updates.

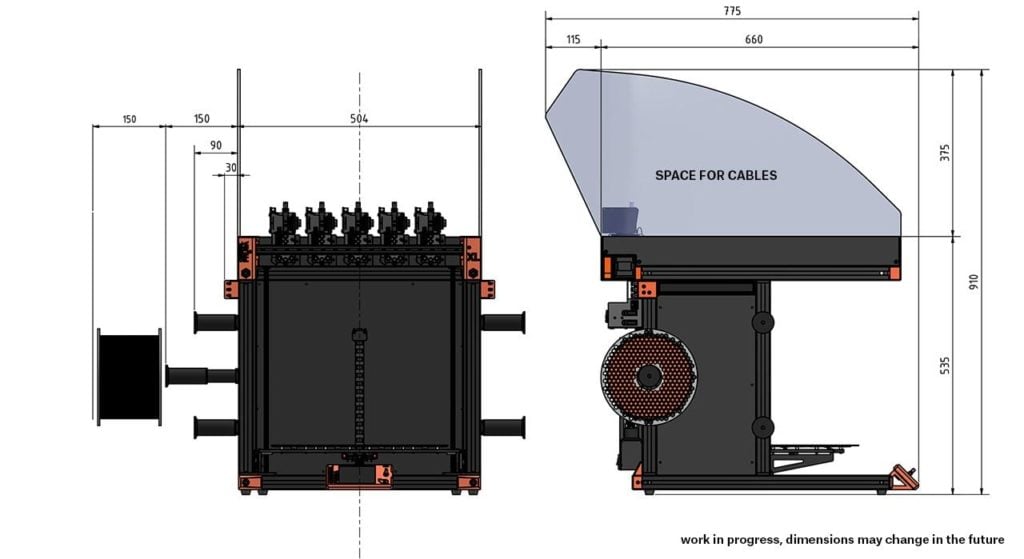

Prusa also showed the full dimensions of the XL 3D printer, including the clearances required on each side of the device.

The other major revelation is that Prusa Research has now set up their own SMT production lines. These will permit the company to manufacture their own printed circuit boards that are used in the XL. This is a huge step as it essentially takes out a massive amount of supply chain risk from their production workflow, and should make deliveries more predictable.

Since they built the SMT lines for the XL, it would not be surprising if they eventually used them to make PCBs for other products, providing similar advantages. Prusa said this is “an incredibly important step forward for us”, and I don’t doubt that at all.

Regarding technical points of the XL development process, Prusa Research revealed they seem to have perfected a method of avoiding wipe towers during multimaterial printing.

Wipe towers are blocks of waste material that attempt to remove drippy bits leftover in idle nozzles that would otherwise make a mess or even corrupt the print. Evidently their new extruder design (the “Nextruder”) is so precise that they can manage these drips with software control, eliminating the need for wipe towers or equivalent.

They’ve also rebuilt their internal system communications to provide an automated way to manage dynamic configuration changes. This is important, as the XL allows for changes of toolheads, and the machine should now be able to detect and track those all by itself.

Prusa Research said they are building several internal prototypes to perform testing, so it sounds like they are still a distance away from a more public beta test of the XL. However, they also say that the machine would be delivered to customers as early as 3Q2022, only a few months away.

The XL could be a breakthrough machine for the professional market, and it sounds like Prusa Research is well on the way to getting it done.

Via PrusaPrinters