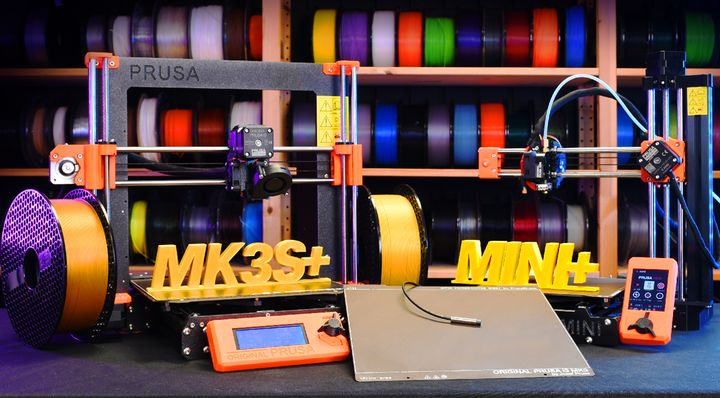

Prusa Research announced they’ve upgraded their current lineup of desktop 3D printers — but only slightly.

In a lengthy blog post by founder Josef Prusa, it was revealed that their flagship FFF desktop 3D printer, the MK3S, is now the MK3S+. The popular Prusa MINI is now the Prusa MINI+. There’s also a few more minor surprises.

We were all expecting the company to be releasing details on new, unreleased products, but apparently they’ve had challenges in doing so. Prusa explained:

“Truth be told, we were expecting that we would be working on something entirely different by now – like putting finishing touches to the XL and the successor to the Original Prusa i3 MK3. However, the current situation makes sourcing new parts much more difficult and we have to find new ways to solve various problems.

So even though we’ve made major progress on our ‘next-gen’ machines, we’re not ready to show them at this very moment. We have something else, though: I would like to announce that the improved models of our 3D printers, the Original Prusa i3 MK3S+ and the Original Prusa MINI+, just arrived!”

That is somewhat disappointing, as I’ve been eagerly anticipating the release of the stretch “XL” machine and some kind of upgraded flagship device. In fact, I recently speculated on what a hypothetical Prusa MK4 could include.

Ironically, in that story I suggested the company might leak out minor improvements in the MK3S, and call it the “MK3S Plus, or something like that.” The name is about the same, but the improvements are not to the degree I suspected.

Prusa MK3S+

What comprises the “+” on these new machines? It turns out there are a couple of changes that don’t really increase the quality of the machine, but instead tend to increase the reliability of its operation.

The main feature seems to be the replacement of the bed sensor. Now, both the MK3S+ and MINI+ include the new “SuperPINDA” sensor. This sensor is not as temperature-sensitive as the previous versions, and thus will be more accurate when sensing the bed’s topology after repeated hot 3D prints. The sensor includes a much higher-quality cable that can withstand far more use.

Prusa says:

“Most of these changes are not major enhancements that would drastically change the behavior of our printers. Think of them as a ‘reliability upgrade’ which is based on the feedback we received from the community, and also by running our printers nearly 24/7 in our print farm. Basically, if your MK3S prints without any issues, the upgrade won’t bring any significant print quality improvements.”

One more change of interest is that the smooth rods on the X and Y axes are now attached by “robust plastic holders” instead of the tie-wraps previously used. That is a holder from very early versions of the machine, and it is long past time for them to be replaced — good job there!

I’ve actually heard some dismiss the MK3S simply due to the tie-wrapped assembly, as some apparently feel that it was not sufficiently rigid. That is in spite of the very high quality of 3D prints that come off the MK3S. Prusa Research might get a few more buyers from this change.

On the MK3S+ there is a minor change to the extruder: they’ve tweaked the filament path slightly to make printing flexible materials a bit more reliable. Flexible materials are notoriously challenging to 3D print for a variety of reasons, and one of them is that the spaghetti-like filament can sometimes curl up in the extruder instead of heading down into the hot end like it is supposed to. Hopefully this change will rectify that issue.

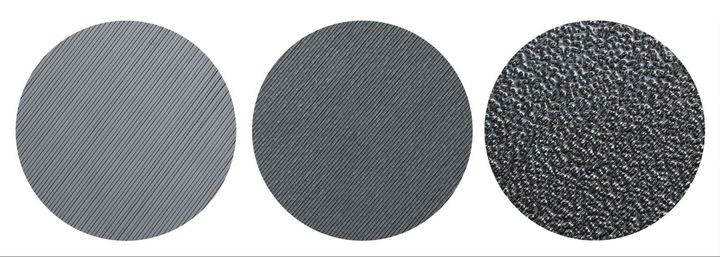

Finally, the company is introducing a third type of print sheet. Currently they offer a smooth sheet with PEI film, and a powder coated “textured” sheet. The new sheet is called “Satin” and its properties lie in-between the two others. The idea here is that while their smooth sheet is great for PLA, it’s not optimal for PETG, and the textured sheet is great for PETG but not so good for PLA. Instead, the new satin sheet is apparently good for not only both of those materials, but also works fine for others, with Prusa saying:

“ASA, Polycarbonate, Polypropylene, flexible filaments or even Nylon, this sheet can handle them all.“

Finally, you might be wondering when they will ship these new machines. It turns out they ALREADY HAVE BEEN! They began shipping these units instead of the original MK3S and MINI devices last week, without announcing anything. That’s reasonable, as the new versions will effectively replace the old versions in the lineup.

Be sure to read the entire saga from Josef Prusa for all the technical details on these changes.

Via Prusa Printers