Prusa Research announced the “Automated Farm System”, a system to control an array of inexpensive 3D printers.

The concept of a 3D printer array is not new; it’s been attempted by several companies over the past few years, with few, if any, having major success. We’ve seen versions from Stratasys, MakerBot, Mass Portal, Voodoo Systems, 3DQue, Mosaic Manufacturing, Loop3D and even Ultimaker, but none seem to have caught on with manufacturers in spite of strong initial interest.

Prusa Research is set to change that with the new Automated Farm System, which has been hinted at by CEO Josef Prusa several times in the past.

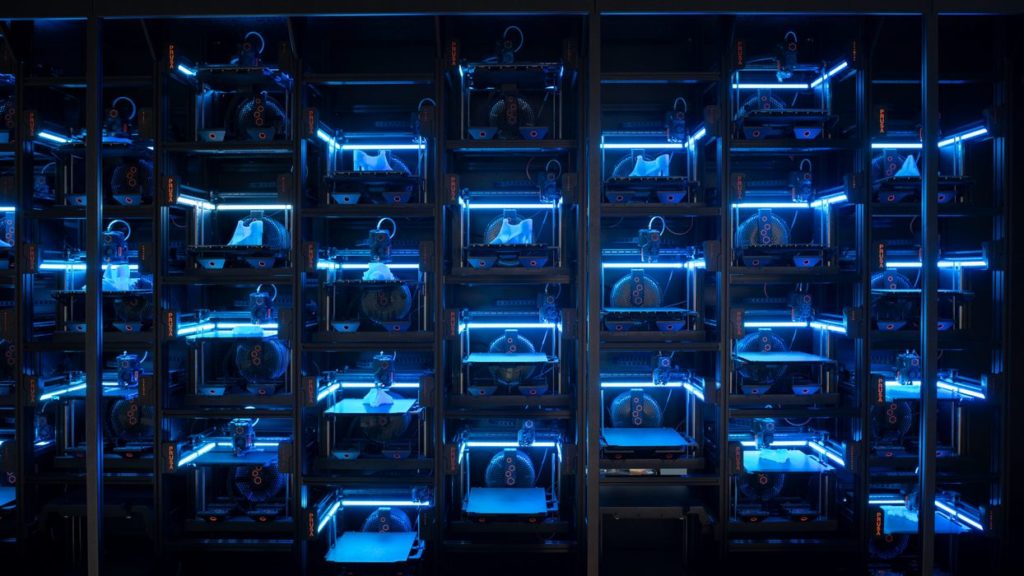

In a way, the AFS’s origin is entirely internal. The company has long been using its own 3D printers to produce parts for new 3D printers. Over the years their print farm has grown substantially, today numbering some 600 devices in their Prague factory.

To run such an amount of 3D printers requires considerable effort, and Prusa Research has long been experimenting with methods of automating their internal labor. Now, it seems they’ve managed to put all that knowledge in a can and market it as the AFS.

The idea of a 3D print array, or “farm” is pretty straightforward, yet provides incredible versatility. Large numbers of parts can be produced in parallel, overcoming the inherent slowness of individual 3D print jobs. Different parts can be produced at the same time by different printer units, overcoming the limitations of traditional mass manufacturing.

In addition, control of an array can simplify labor efforts by remotely controlling all the devices as much as possible.

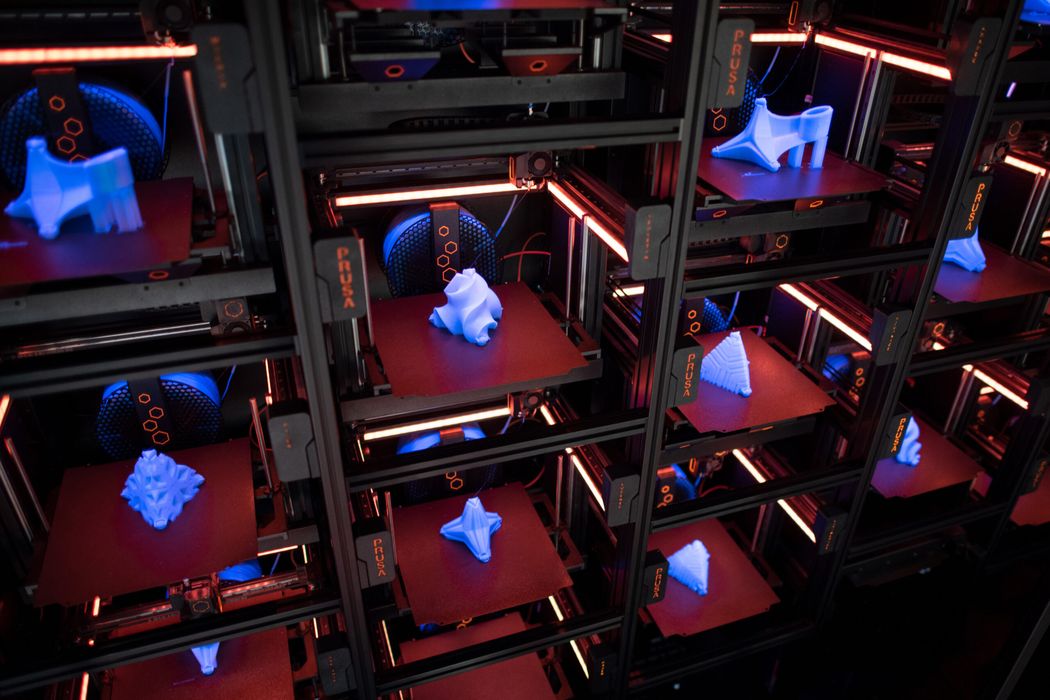

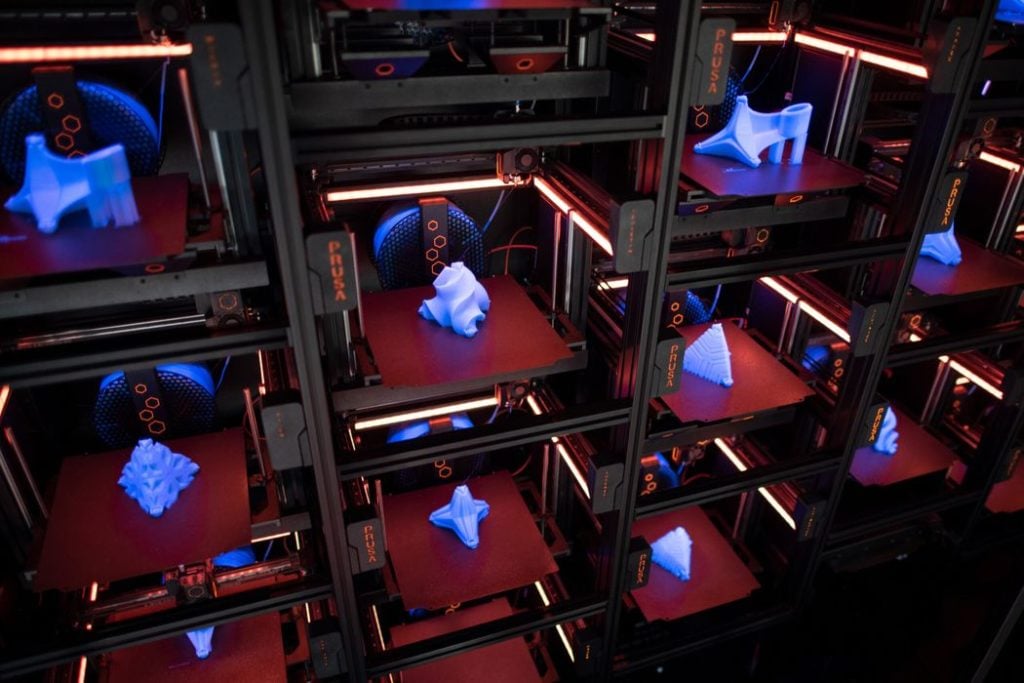

Those characteristics are indeed present in the AFS, which is to debut at Expo 2022 in Dubai as part of the Czechia exhibit. The Dubai display will involve an array of 34 “new CoreXY Original Prusa 3D printers” that are not quite the expected Prusa XL device rumored for some time. However, for purposes of the AFS demonstration, they will be ideal.

The AFS involves a racking system that allows quick swap of whole 3D printers. Should one require service, it can be easily pulled out for repair and another put in its place. Prusa Research describes this as a “rack like” system for 3D printers.

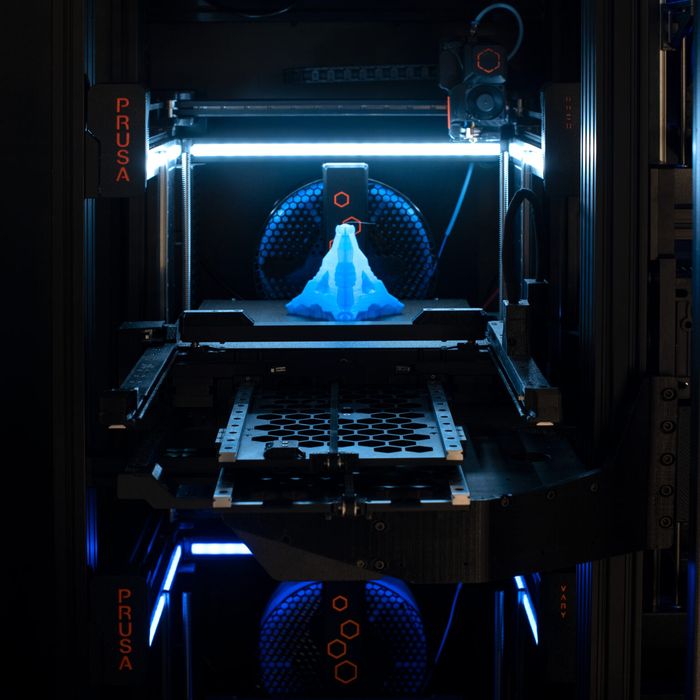

The major challenge with 3D print automation is the requirement for removal of completed prints. Normally this is done using manual effort, which as you might expect is expensive, inconsistent and not a particularly interesting task.

There have been multiple attempts at automated print removal by several companies using unique hardware solutions. However, Prusa Research is using a straightforward approach here: a robotic arm will remove completed print plates from printers and shuffle them to an unloading station. For the Dubai display, prints will be simply collected in bins, but the possibility remains they could be shunted off for other processing, such as smoothing, painting or even assembly.

Prusa Research has developed a new software tool they call “Prusa Connect” to control the AFS. Apparently this is a rather intelligent system. They explain:

“Our new software called Prusa Connect controls everything: when you select a file to print, it finds the best machine for the job automatically (e.g., a machine that just finished printing and is not fully cooled down yet, so getting back to operating temperatures will be faster and more efficient). Prusa Connect keeps track of all print jobs, statistics, remaining time, and other crucial settings and statistics. Once an object is finished, the software automatically sends a mechanical arm that lifts the print sheet, moves it towards the collecting area where the object is detached from the sheet and delivers the part to the collection bin. The print sheet is then returned to the printer.”

The AFS is designed to be flexible, and can be constructed with different capacities and possibly even different types of 3D printers in the array.

Prusa Research expects to offer the AFS at a reasonable price, and is targeting US$3000 per printer for “large farms”. At that price, the 34-unit Dubai display would cost US$102,000. However, “34” might not be a “large farm”, so the cost could be higher. Prusa Research’s own 600-unit farm would cost US$1.8M at that unit price for perspective.

The AFS is a massive step for Prusa Research, as it formalizes their offering to larger-scale manufacturing, a market they haven’t truly addressed with their individual-oriented products to this point. While they do have clients purchasing quantities of current equipment and using them in self-built farms, these customers now have an option to supercharge their operations using Prusa Connect and the AFS.

I’m very curious to see how this plays out. Will the Prusa AFS be widely accepted by industry where other options were not? If they do, Prusa will no doubt have to expand their own farm to produce even more 3D printer parts.

Via PrusaPrinters