Prusa Research significantly updated their SL1 MSLA 3D printer.

The new device, the SL1S, with the extra “S” for “SPEED”, is as you might suspect, a lot faster when 3D printing than its predecessor.

Like they’ve done with all their previous devices, Prusa Research has learned from experience to redesign the next version. The SL1S offers bigger prints, better quality and a host of improved ease-of-use features.

While the pixel resolution on their LCD array remains at 2560 x 1620, it’s delivered by a 5.96” array rather than the old SL1’s 5.5” version. This means the build volume on the SL1S increases to 127 x 80 x 150 mm from the SL1’s 120 x 68 x 150 mm.

SL1S Monochrome LCD

There’s something else with that LCD array: it’s monochrome instead of RGB. RGB arrays include filters to produce color for visual applications, but for MSLA 3D printing they simply reduce the energy transmitted through them. With a monochrome screen much more energy travels through, which in MSLA systems cures the photopolymer resin much more quickly.

In other words, the “S” in the SL1S is a real thing: the SL1S can 3D print a 150mm object in only two hours. Layers can be cured in transparent resin in as little as 1.3 seconds, while cloudy resins, like Prusa’s Tough resin line, take only 1.6-2.5 seconds. That’s a lot faster than the SL1.

The SL1 was already relatively fast to print as it used an unusual combo peeling motion where the resin tank itself would tip in addition to having the build plate rise slightly on each layer. This is quicker to execute and helps keep the resin mixed properly. The SL1S keeps this highly useful feature.

Prusa Research believes the added power of the monochrome LCD array will permit industrial users to experiment with unusual photopolymer resins that would otherwise take too long to cure.

The new array should also last far longer, because it operates with less time per layer.

To accommodate the new array, Prusa Research redesigned the optical system, shown here. The new design increases the quality of 3D prints with a far more powerful LED light source that delivers 4X as many UV photons as the SL1.

SL1S Usability Features

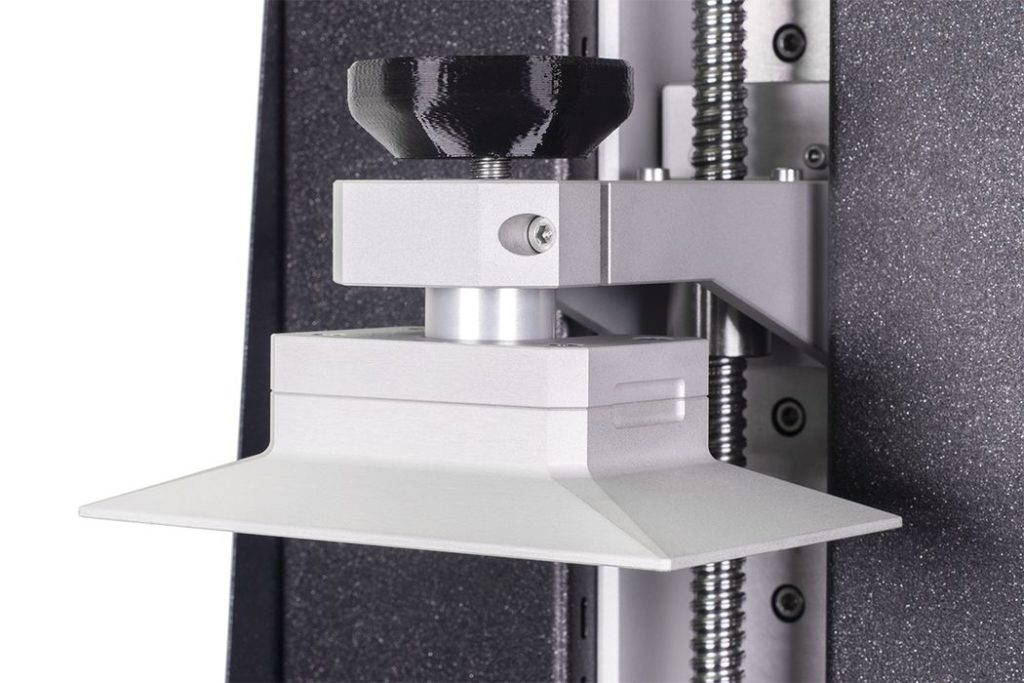

The SL1S has some additional handy features, such as this redesigned build plate that now has sloping sides. This allows resin to drip off safely into the resin tank and avoid unexpected drips when moving the build plate to the washer. This feature should be standard on all resin 3D printers, but unfortunately it is not.

Another very useful upgrade is a change to the resin tank. Instead of an aluminum tank, the new SL1S includes a nylon tank that is easily removable and has a snap-on lid. This means you can now safely store half-used resin in these protective tanks when swapping materials. That’s a far less messy approach, where otherwise you’d be carefully pouring resin back into bottles — and inevitably spilling some in the process.

Prusa Curing and Washing Machine

Along with the SL1S, Prusa Research has also updated their post-processing device, the Curing and Washing Machine. This machine can now pre-heat resins, as well as washing resin away with an IPA bath, and curing the prints with additional UV light exposure.

However, Prusa Research has encountered supply chain troubles and has been forced to not only increase the price of the wash station, but eliminate the kit version. They say, however, that very few purchased the kit version, which makes sense to me as resin 3D printer operators would have far lower tendencies to fiddle with equipment.

SL1S Pricing and Availability

The SL1S and the new Curing and Washing Machine are now available from Prusa Research in their online store for US$1,999 and US$749, respectively. They also offer a bundle for both devices at US$2,599.

One more thing: any outstanding orders for the older SL1 are now automatically changed to SL1S orders by Prusa Research, with no additional cost owed by the SL1 purchaser. That’s a nice touch!

Via Prusa Printers