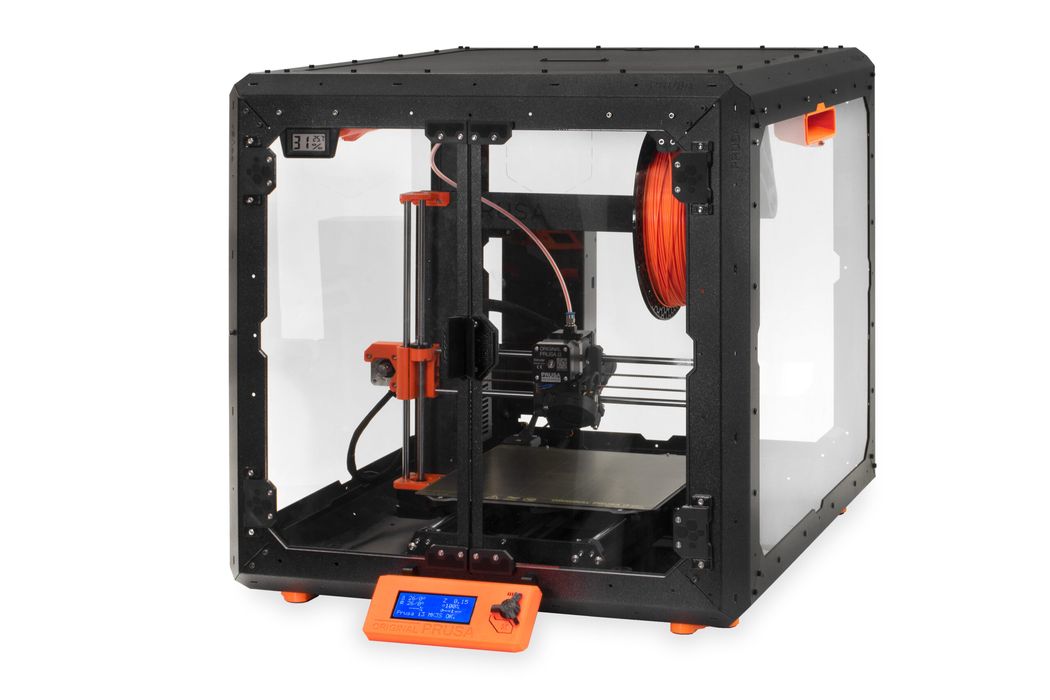

Prusa Research announced the availability of a new, sophisticated enclosure for their popular MK3S+ 3D printer.

The company had previously issued instructions on how to build a basic enclosure at low cost using parts from IKEA. While that option is still usable for those on a budget, the new Original Prusa Enclosure offers many more advanced features.

Why use an enclosure at all? The main reason has to do with temperature. Certain materials tend to warp when 3D printed on open gantry devices as the thermal gradient between freshly extruded material and the ambient air causes the print to distort. In some cases this can cause the print to fail and even damage the machine. An enclosure will capture stray heat from the print surface and hot end, decreasing the thermal gradient and reducing the probability of warping.

However, there are a number of other reasons for using an enclosure:

- Safety: an enclosure can prevent incursion into the active build area by children or pets

- Odor: some materials emit noxious fumes when heated, and an enclosure can keep them from circulating

- Cleanliness: open gantry machines are subject to dust landing on the machine, and an enclosure prevents this

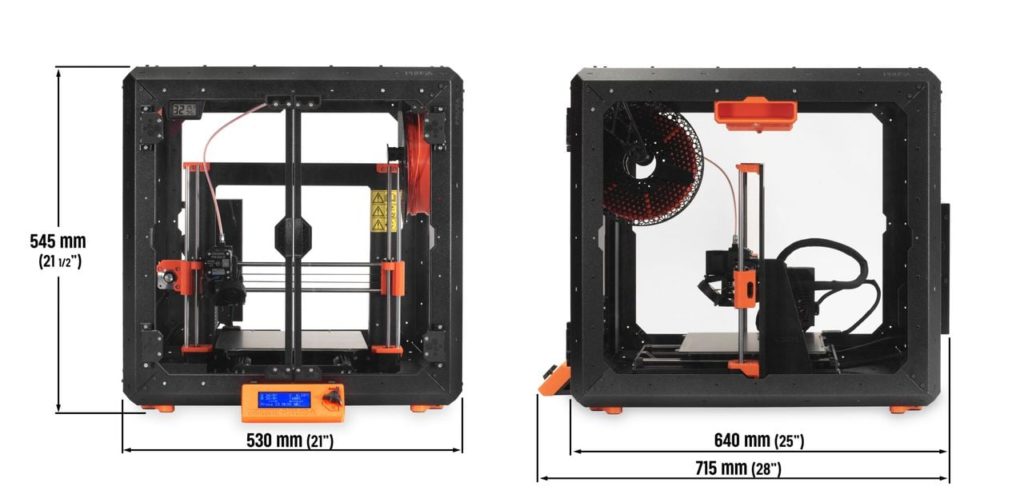

The new Original Prusa Enclosure does all that and quite a bit more. It’s actually a very advanced design, far more than I had assumed. In fact, the enclosure itself weighs an amazing 10kg (22lbs), demonstrating that it is a lot more than six flat panels stapled together.

Prusa Research ships the enclosure as a kit, but includes all required parts to assemble it. This is similar to their 3D printer line, where many of the devices require user assembly. The enclosure is sized to fit the MK3S+, and apparently with some modifications can accommodate the prior MKS2.5 device. I suspect it may also be usable on third party equipment, if it fits properly in the enclosure.

Prusa Research said the enclosure will permit the operator to attempt 3D printing certain higher temperature materials:

“Some materials are more difficult to print than others. Our enclosure creates a stable environment with an increased temperature that prevents advanced materials from warping and detaching from the print sheet.”

They specifically mention PP, PA, and PC materials.

It’s also possible to place a spool inside the enclosure, which would pre-heat the material slightly and thus potentially increase print quality and reliability.

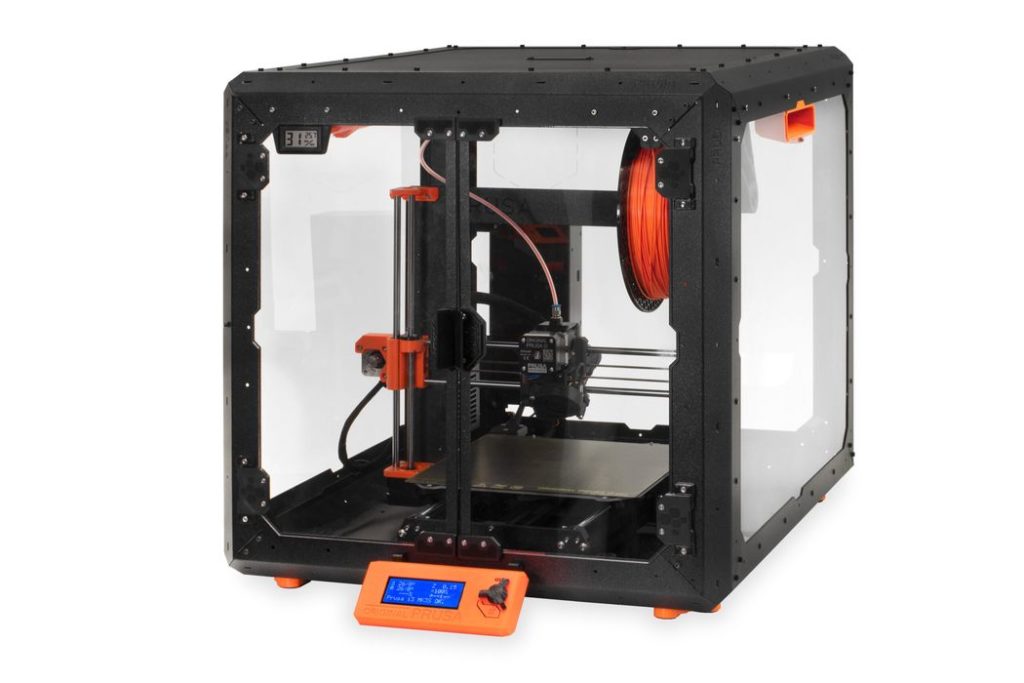

The MK3S+ has the ability to detach its control panel and mount it on the outside of the enclosure. This is quite interesting, as it keeps the electronics from being exposed to heat. However, the MK2.5S model has a different setup and it doesn’t look like that machine’s panel can be moved in a similar manner.

One very intriguing feature is that the Original Prusa Enclosure can be stacked! This means that an operator could place several devices on the same footprint, saving considerable space. There are an increasing number of small production workshops using multiple devices, so this could be a big seller in that group.

On the front of the enclosure is a temperature monitor that shows both internal and ambient temperatures, something I always wonder about when using enclosures on other machines.

The enclosure also supports the Prusa MMU2S, a multimaterial accessory for the printer that allows use of up to five different filaments within a print job. The MMU2S sticks up above the main machine slightly, so they’ve adjusted the vertical space to accommodate it. While you can place one spool inside the enclosure, I suspect the remaining four might have to remain outside the enclosure.

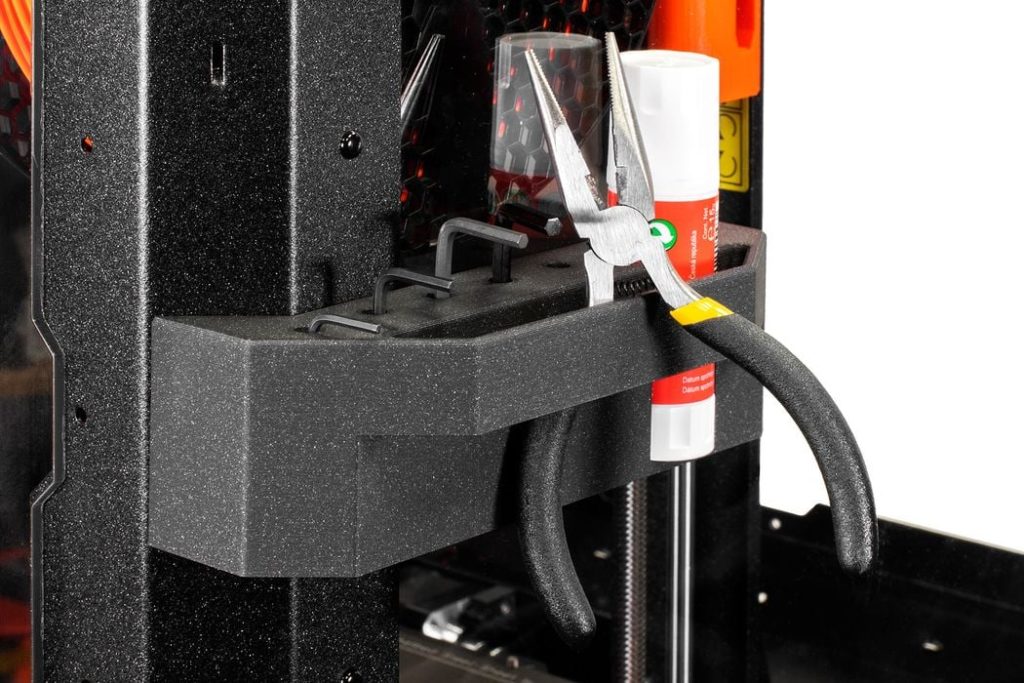

Prusa Research makes a big deal of the ability to modify the enclosure, and that’s something that their client base will almost certainly do. For example, the enclosure includes a variety of mount points where operators could place tools, cameras or other useful items.

There are several optional features available for the Original Prusa Enclosure:

- A filtration system that would pull air from the chamber and filter it before exhausting to the room. This might also moderate the temperature of the chamber if it gets too high

- For EU customers, they offer a fire suppression system that could extinguish fires from damaged equipment

- A lock system can be mounted on the doors to keep unauthorized personnel away from the machine’s insides

- A quick-release power cable allows easy removal of the machine if required

- An LED light strip will illuminate the build chamber, allowing proper viewing of the print job by humans and cameras

They’re also working on what they call a “Smart Box” that could coordinate and control all of the accessory systems, including some new items like thermal sensors, automated door locks and even print job monitoring. Finally, they intend on publishing a series of free modifications and accessories for the enclosure on Printables.

The presence of this product could rattle some of Prusa Research’s competitors that do offer equipment with enclosures. Up to now they’ve been able to say their equipment is better because of the enclosure. But not anymore, and it may be that the cost of a MK3S+ and enclosure could be far less than some competitive enclosed machines.

They’ve set the price of the base enclosure at US$349. That may seem like a steep price, given that it is possible to buy certain inexpensive 3D printers for that price. However, the enclosure is not a 3D printer: it makes a 3D printer better. This price point is also lower than competing commercial enclosures that don’t always offer as much functionality.

The Original Prusa Enclosure will not be for everyone, but there are certainly many that need something like this product. I believe Prusa Research will sell a great many of these enclosures.

Finally, I’m wondering if and when their competitors will try to match with their own enclosure designs.

Via Prusa Research