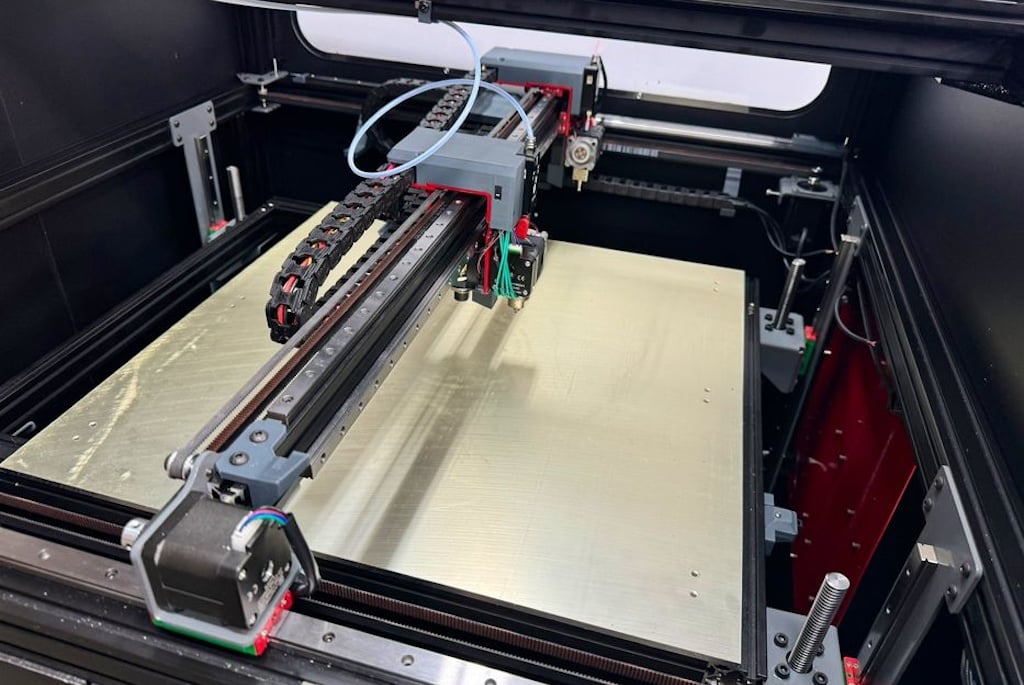

We’ve received a lot more information about Project R3D’s Talos high speed 3D printers.

The Chicago-based company first announced the Talos series only a few weeks ago in early September. Now the company seems to be shipping them to customers after only a few weeks.

The Talos series is comprised of three models, the 600, 1200 and 1800, which have similar features but considerably different build volumes.

All devices include independent extrusion systems (IDEX), and can operate at very high print speeds, but more about that later. The print volumes are large, and the company offers optional enclosures for each of the three models.

The largest of the three is the massive Talos 1800, which sports a huge build volume of 600 x 1800 x 600 mm. This easily puts the device in the “large format” category, as its X-axis dimension is almost two meters long.

There are three options for extruder & hot end choice with these machines:

- E3D Revo Hemera XS

- Mosquito Magnum/LGX

- Mosquito Magnum+/LGX ACE

Note that the Revo option would provide a means for easy swapping with other Revo-compatible hot ends for different materials and applications.

About that print speed: Project R3D said the machines can achieve a print speed of up to 1000mm/s, which is one of the fastest we’ve heard of, and is vastly more than typical professional machine speeds of 80-100mm/s.

It’s not clear how they achieve that speed, aside from apparently robust mechanical components. However, I suspect they are doing some form of vibration compensation, perhaps with Klipper firmware under the hood.

The speed is of critical importance for large machines such as these. Without high speeds, large prints could literally take days or weeks to complete. By speeding up printing large jobs could take much more reasonable durations, perhaps even hours in some cases.

That also doesn’t account for the possibility of using extra-wide nozzles, which would also significantly increase print speed. Large diameter nozzles are often used on large-format equipment because the need for fine details is often not required on large parts.

Project R3D said the machines are suitable for use in automotive, aerospace, military and cosplay applications.

Via Project R3D