Charles R. Goulding and Preeti Sulibhavi discuss Rice University’s ongoing efforts to pioneer the use of self-assembling peptides as bioink for 3D printing.

In the Spring 2023 issue of Rice Magazine, the bioscience section showcased what researchers at Rice’s Hartgerink lab have been developing by essentially bioprinting peptides.

Peptides are chains of 50 or fewer amino acids, which are the organic, chemical building blocks of all proteins. There are 20 naturally occurring amino acids that makeup all the proteins in the human body in some permutation or other.

There is a class of self-assembling peptides that can arrange themselves solely based on structure and chemical composition. Referred to as multidomain peptides, they assemble into a water-based, gelatinous material or hydrogel.

Researchers can use multidomain peptides for soft robotic projects, bioengineering in the field of soft tissue as well as wastewater treatment. The researchers have been able to demonstrate the regenerative and healing properties of these peptides and how they serve as a great 3D printing, bioink (when the peptides are concentrated further).

To quote Rice Magazine:

“Multidomain peptides have been used for nerve regeneration, cancer treatment and would healing and have been shown to promote high levels of cell infiltration and tissue development when implanted in living organisms.” The concentrated peptides are proving to be very compatible as a bioink.

Self-assembling peptides used as bioink is a pioneering advancement in the field of biomedical engineering. The fact that these peptides can “self-assemble” makes them prime candidates for 3D printing bioink since they can reassemble after being mixed into a concentrated 3D printing material. It can revolutionize the way patients with degenerative diseases are treated and can vastly improve those health outcomes.

3D Printing and Bioinks

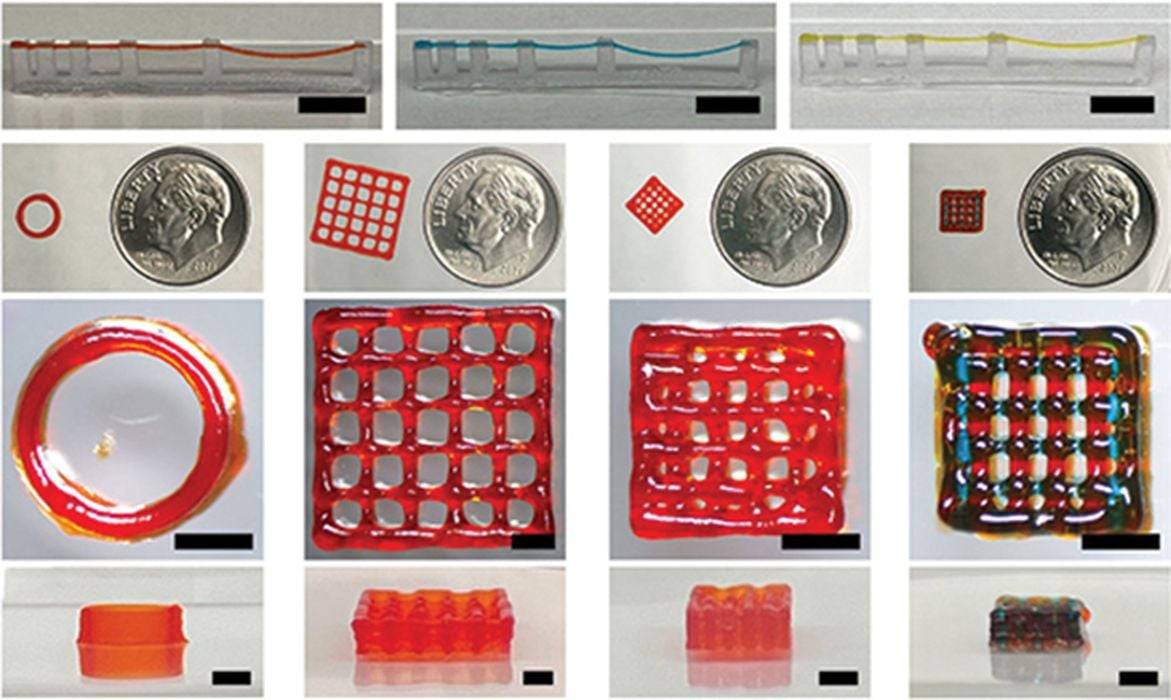

The key to this novel development is the fact that advanced bioink designs can use various methods of dissipating mechanical energy that can be focused on developing next-generation, cellularized 3D scaffolds, as opposed to 2D. These 3D scaffolds mimic anatomical size, tissue architecture, and tissue-specific functions. These next-generation bioink need to have high 3D printing fidelity and should provide a biocompatible microenvironment along with improved mechanical properties.

To design and develop these advanced bioink formulations, it is important to understand the structure-property-function relationships of hydrogel networks. By specifically leveraging biophysical and biochemical characteristics of hydrogel networks, high performance bioinks can be designed to control and direct cell functions. The possibilities for medical applications are limitless.

The hydrogels provide mechanical support to the cells and encapsulate them without damaging them. They can also control cell growth patterns and behavior. A system of multiple peptides makes it possible to modify the properties to control the cells and incorporate various functionalities. One such application is to attach an enzyme that stimulates the growth of bone. And the degree of cross-linking can be adjusted and altered to match the properties of different tissues that support the human body. In a sense, bioprinting helps the bioink “mimic” the properties of the proteins in the human body.

From cancer to orthopedics, bioprinting self-assembling peptides is a real game changer for the healthcare industry.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

A patient who has been told that they must live with a chronic condition that alters they path of their life forever can now find hope in their future, thanks to bioprinting researchers at Rice University as well as other institutions and laboratories developing self-assembling bioinks. While this research is still in the early stages, the potential for human application is real. Support for biomedical engineering teams designing and developing such methods for treatment is critical.