Researchers have developed a mathematical model to predict extrusion widths to improve 3D print quality.

3D printing using the FFF process is extraordinarily complex. While it seems that the soft thermoplastic simply pushes out of the nozzle, there are countless factors involved.

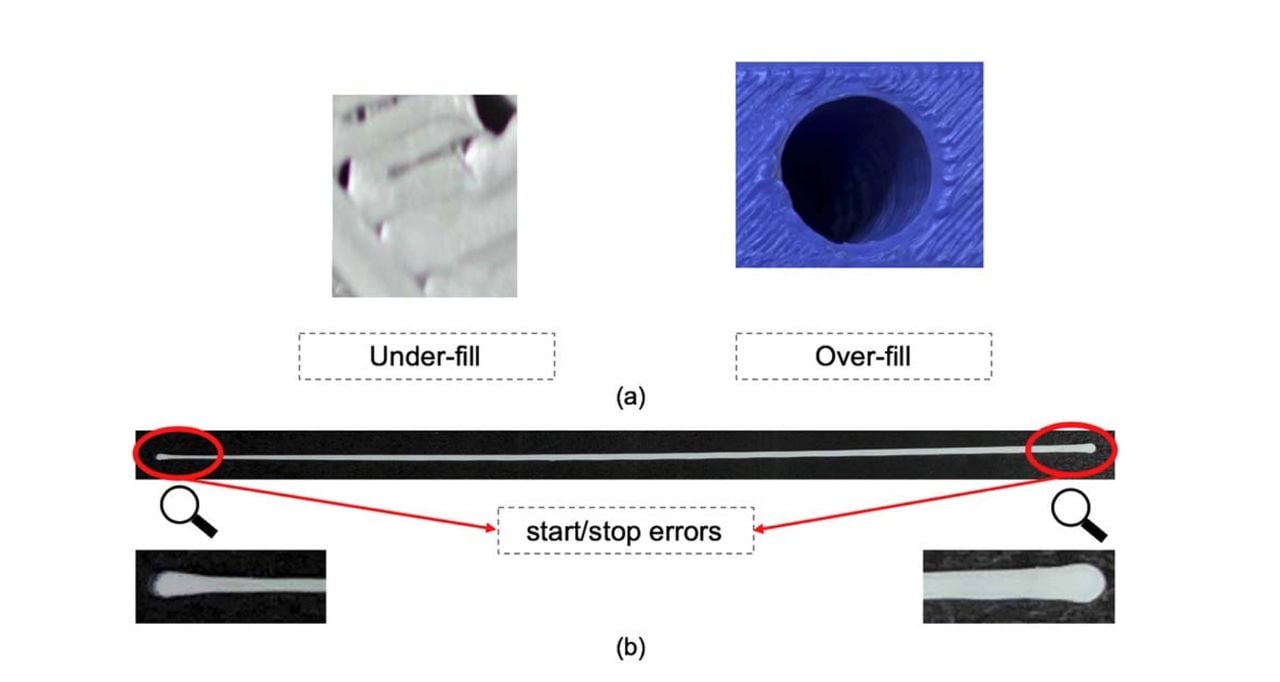

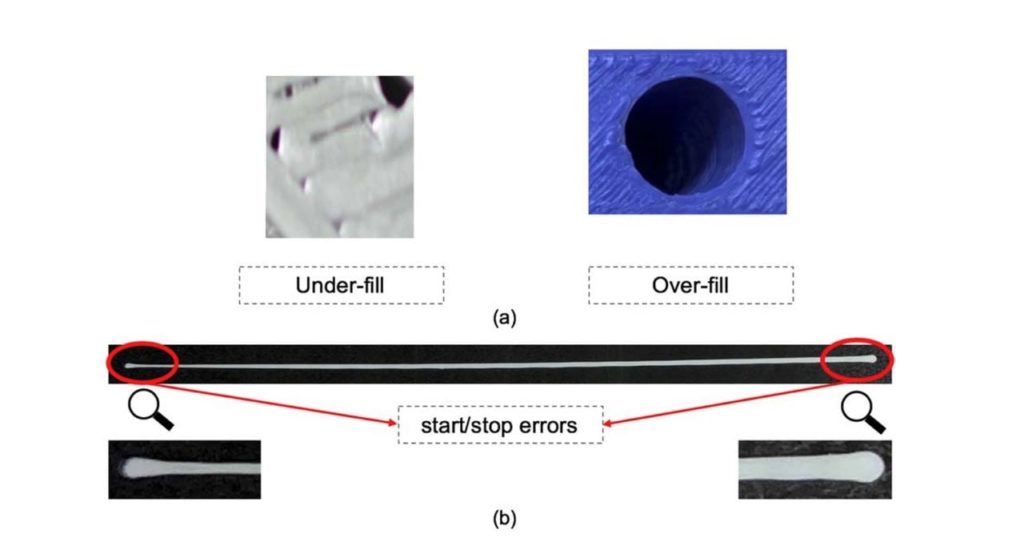

The problem is that the variability of numerous in-print situations results in unpredictable extrusions. These can lead to decreased part quality, that’s becoming far more important.

To those 3D printing plastic dragons, it’s not a big issue. But to those considering using an FFF setup for production end-use part purposes, it’s another story. Production parts must be made to specific quality measures, and not vary from them. That’s actually quite challenging to achieve.

The issue lies in the print parameters that drive the motion system during extrusion. Temperatures, speeds, flow rates, accelerations, and other factors all combine to form the extrusion. These can appear in all manner of combinations during arbitrary print jobs.

The new research attempts to figure out how to predict extrusions. They explain:

“There is a lack of a quantitative understanding of the impact of printing kinematics on such variations to guide the printing process control. This article deals with the challenge by establishing a mathematical model that quantifies the printing width variations along the printing paths induced by printing speed and acceleration.”

This is quite interesting, because this mathematical model could be incorporated into future slicing software to make adjustments to ensure “perfect” extrusions for a given geometry.

An interesting side effect of the model is that it can be used to monitor variations between print jobs on similar equipment. This could identify issues present in the equipment, or perhaps even suggest frequency of maintenance cycles.

The researchers are able to predict the results from a printer they from which they have only limited test data.

They identified five phases of extrusion, each of which affects the quality of the extrusion in different ways:

- Phase 1: Pre-Action, The nozzle begins moving and the line width increases

- Phase 2: Warm-Up 1, The nozzle continues accelerating and the line width continues to increase

- Phase 3: Warm-Up 2, The nozzle reaches the specified speed and the line width keeps increasing

- Phase 4: Steady, The line width reaches nominal width and remains constant, and the nozzle remains at constant speed

- Phase 5: Slow-Down, The nozzle starts to decelerate and the printing line width starts to increase

These effects can be seen in the image at top, and certainly can affect print quality. It appears their model amounts for these phases and thus the flows could be adjusted accordingly.

In this chart you can see that they have correctly predicted the line width at two different print speeds.

This is intriguing research that I hope will be integrated into 3D print slicing systems as soon as possible. If so, then print quality should instantly increase as the correct extrusions should always occur.

Via IEEE