After yesterday’s story about how desktop 3D printer buying strategies are shifting, I thought about what kind of machines might be offered in the near future.

3D printers have always evolved, and done so rapidly. Every year machines have increased in capabilities, reliability, convenience features and print quality. Prices have also generally gone down in the long term, although they tend to occasionally bounce up temporarily as new generations of equipment emerge with new features.

Today’s FFF devices include a number of de factor standard features that might have been considered advanced (and expensive) years ago. Some of these include:

- Automated leveling

- Touch screen control

- Simplified assembly

- 32-bit controller boards

- Filament-out detection and recovery

- Power-out detection and recovery

- Silent stepper motors

- Magnetically attached PEI-style print plate

- Starter set of print parameters

You probably wouldn’t consider buying a machine without those today, but there was a time not that long ago when NONE of these were present on typical equipment.

Today we see more features emerging, including:

- Advanced calibration

- Use of AI

- Higher speeds

- Higher temperatures

So far these and several other advanced features are only beginning to appear on more expensive desktop equipment. However, if the pattern holds we will see these and others seep down into lower priced models eventually, and they’ll become standard features everyone expects.

This sequence of events isn’t going to stop. There will be more innovations to come over the next few years, and the “standard” machine of the future will include these innovations.

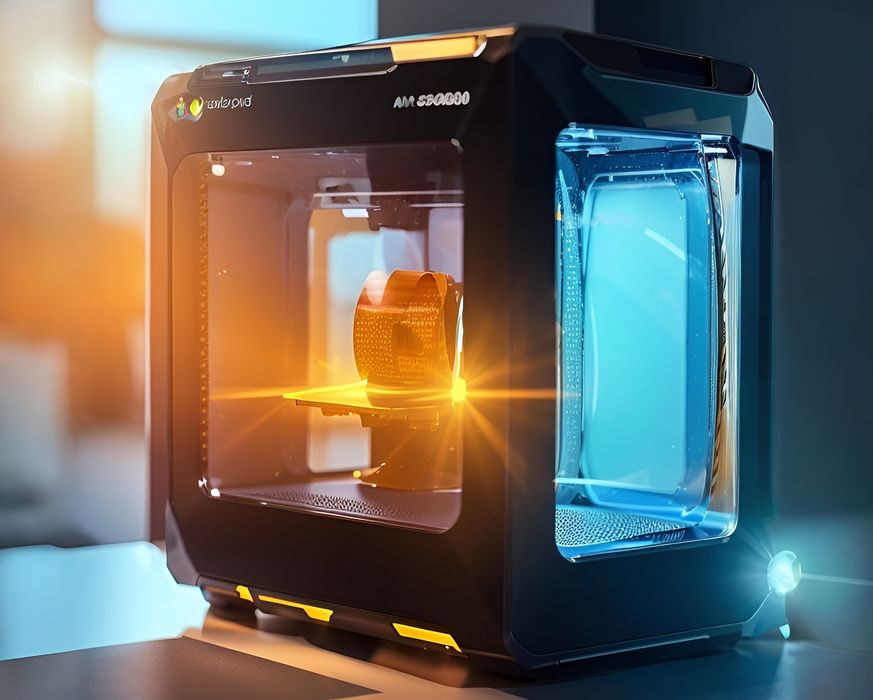

But what might that machine look like? What could typical specifications look like?

I prepared what could be the specs for a hypothetical typical desktop FFF 3D printer of 2026, three years from now, based on the trends of today and some speculation.

First, I suspect that FFF will still be in force as the main desktop 3D printing process. It’s unlikely we will see it replaced within three years by an alternate process, such as volumetric.

2026 Hypothetical Standard Specifications

- Build volume: 300 x 300 x 300 mm

- CoreXY design

- Rigid metal frame

- Actively heated build chamber to 50C

- Fully assembled

- Fully enclosed with magnetic locking door

- Activated carbon/HEPA filtering system

- Responsive full color touch screen

- USB-C, WiFi, Ethernet, MicroSD interfaces

- 1.75mm filament

- Dual independent extruders (IDEX)

- 0.4mm hardened, quick-swap nozzles

- 300C maximum extrusion temperature

- Nozzle wipe station

- High-grip extrusion mechanism

- “Surround” cooling fans and ducts

- High volume all-metal hot end with ceramic heater

- 600mm/s maximum print speed

- Printer self-checking system

- AI-powered closed loop motion system monitoring and tuning

- LiDAR sensor-based bed leveling

- LiDAR sensor-based quality assurance throughout jobs

- Onboard camera for remote monitoring and AI failure detection

- Bright internal lighting

- Anti-vibration firmware

- Optional cloud-based job preparation, dispatch, monitoring and control

- Heated spool storage in build chamber

In other words, tomorrow’s standard desktop FFF 3D printers will begin to resemble today’s more advanced 3D printers. What might be the cost of such equipment? Like it always does, the average price level will probably fall to something around US$200-400 for such a machine.

At that price and the power of these advanced machines, it would be reasonable to believe there could be increased sales and adoption of desktop 3D printing by 2026. This would be particularly so if software advanced in parallel to provide more easy access to usable 3D models for printing.

That would in turn open up the possibility for even more advanced equipment at even higher prices, just as it always does. What those machines might include, I cannot say.

How do you feel about this list of standard features? Would you add more? Or feel the machines of 2026 won’t get that far?

The future of hobby 3d printing is the past of additive manufacturing

2 component inkjet.

Wax/soluble wax

Wax/photopolymer

Single jet per substance ala solidscape

or

arrays of jets ala 3d systems

The patents are open. Industrial knockoffs are popping up at slight discounts from the originals.

Its only a matter of time until someone starts marketing deposition printheads to hobbyists.

All sounds great except for the Dual IDEX print heads. My experience so far with a dual head machine is not great. Very hard to have both heads perfectly aligned especially if they are mounted on the same gantry. With increased print speeds the need for multiple heads printing at the same time is less necessary. I’m curious how the multiple swap-out heads PRUSA XL shakes out.